Bending Roller

The axial stretch roll, also known as the bending roll, consists of a high-quality aluminum alloy rubber sleeve, a bent iron core assembly, a bracket base and a hand lever adjuster. It has the function of adjusting tension, leveling the substrate, eliminating the wrinkles and wrinkles of the...

The axial stretch roll, also known as the bending roll, consists of a high-quality aluminum alloy rubber sleeve, a bent iron core assembly, a bracket base and a hand lever adjuster. It has the function of adjusting tension, leveling the substrate, eliminating the wrinkles and wrinkles of the substrate. It is suitable for processing machinery for paper, film, textile, metal foil and other products, especially for PE, PVC and other substrates.

The axial stretching roller has the following characteristics:

1. The axial stretching roller can be adjusted in the range of 1~10, which can effectively and evenly stretch the substrate;

2. The stretch strip is made of silica gel material, which can effectively keep the roller surface clean and avoid damage to the substrate;

3. The roller body has small rotation torque and flexible operation;

4. Rotating power can be added as needed.

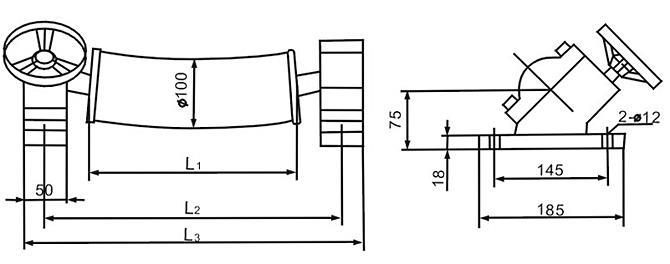

Technical parameters

| No | L1 | L2 | L3 | Remarks |

| 1 | 600 | 710 | 760 | Applied to the base material width of 500mm |

| 2 | 700 | 835 | 885 | Applied to the base material width of 600mm |

| 3 | 1200 | 1320 | 1370 | Applied to the base material width of 1100mm |

| 4 | 1400 | 1488 | 1538 | Applied to the base material width of 1300mm |

| 5 | 1600 | 1690 | 1740 | Applied to the base material width of 1500mm |

| 6 | 1900 | 1985 | 2035 | Applied to the base material width of 1800mm |

| 7 | 2100 | 2180 | 2230 | Applied to the base material width of 2000mm |

| 8 | 2300 | 2353 | 2403 | Applied to the base material width of 2200mm |

Ordering instructions, please note

● Roller length

● Mandrel length

● Roller diameter

● Line speed

Method for increasing the service life of the flattening roller

In order to improve the wear resistance and crack resistance of the flattening roller, the plasma cladding technology is mainly used to melt and cover Al2O3 on the surface of 45 steel and doped with Fe-Ni based high temperature wear resistant alloy coating. This process is roughly 45 round steel blank → guide roll blank → plasma cladding → guide roller surface grinding treatment → plasma alloy guide roller.

After inspection, the coating obtained according to the above plasma cladding process is uniform and dense, and has no pores and no cracks. Because the 45 steel matrix has good thermal conductivity, the solidification speed is fast when cooled in air, so the structure of the obtained coating and the precipitated phase inside it are very fine and uniform.

Comparing the plasma alloy guide rolls with conventional high chromium cast steel guide rolls, their service life is significantly improved. The service life of the high-chromium cast steel guide rolls is mostly 8 hours, then serious wear grooves and fatigue cracks will occur, and the deep grooves generated by the wear will cause sticking steel and calendering, and the surface quality of the steel. There is a big impact, and then it will be scrapped. The plasma alloy guide roller has remarkable resistance to abrasive wear and thermal fatigue resistance, and its average service life can reach 138 hours. In addition, after repairing the guide roller, its average life can reach 96 hours, and the effect is very obvious.

Through comprehensive evaluation of the plasma alloy guide rolls, it can be known that the application of the plasma cladding technology on the guide rolls of the rolling mill can significantly improve the service life of the guide rolls of the rolling mill, which can reduce the cost of guide roller handling and loading, and reduce the labor intensity of frequent replacement. Because of the waste of rolling work time caused by the disassembly and handling of the guide roller, and the increase in the amount of steel rolling, a large amount of high-quality steel can be saved, and at the same time, the safety accident caused by the damage of the guide roller can be reduced.

Packing

Order Details

Item Name | Bending roller |

MOQ(Minimum Order Quantity) | 1PC |

Lead time | 10-15 days after receiving the deposit |

Calculated Weight | Need to count |

Package | Wooden Box/Pallet packing/according to clients's requirement and demand |

Price Term | EXW,FOB, CIF, etc |

| Payment term | TT,L/C,Western Union |

| Country of Origin | China |

Hot Tags: bending roller, China, manufacturers, suppliers, factory, quotation, pricelist, buy