Aluminum Alloy Guide Roller For Printing Machine

1.Introductions of aluminum guide roller We adopt high quality aluminum alloy as the body material,use extrusion molding and make ribs structure inside.The outside diameter can be made from 25mm to 320mm.Under the treatment by computer balancing correction process,the dynamic balance of the...

1.Introductions of aluminum guide roller

We adopt high quality aluminum alloy as the body material,use extrusion molding and make ribs structure inside.The outside diameter can be made from 25mm to 320mm.Under the treatment by computer balancing correction process,the dynamic balance of the aluminum roller will be smaller than 2g.With using of sophisticated equipment and special tools,the roll surface gloss can be 0.8,concentricity can reach 0.02mm.

Special treatment in the shaft axle and the using of imported bearings will make sure the the aluminum guide roller work very well at high speed with no deformation.

Advantages Of JCTPRINT Aluminum Guide Rollers:

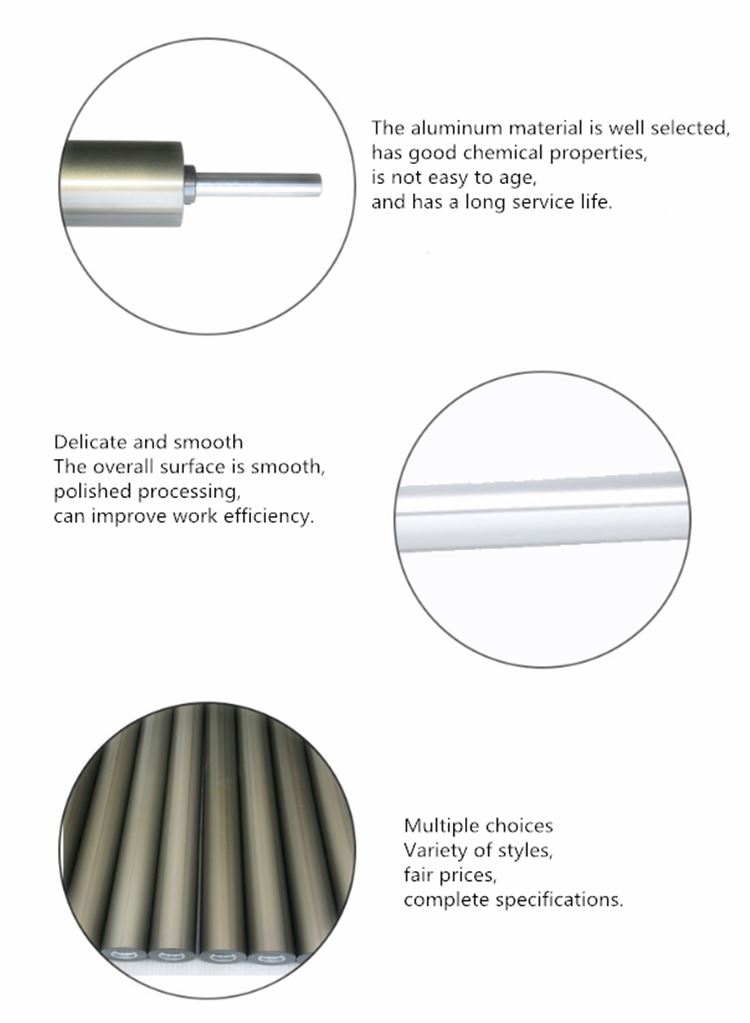

Good material

The aluminum material is well selected, has good chemical properties, is not easy to age, and has a long service life.

Delicate and smooth

The overall surface is smooth, polished processing, can improve work efficiency.

Multiple choices

Variety of styles, fair prices, complete specifications.

2.Features and applications

Our aluminum guide rollers have the characteristics of high strength, low resistance, light weight, flexible rotation, no-rusty, wear resistance and corrosion resistance.

Aluminum guide rollers are widely used in printing, packaging plastics, paper, glass, pharmaceutical, electronics batteries, textile machinery and industries.

|

Body material |

Aluminum |

|

Diameter |

22-320mm |

|

Length |

100-6000mm |

|

Weight |

1-100kg |

|

Anodize |

HV300/HV700 |

|

Thickness of anodize |

20-80μm |

|

Type |

Without shaft/ With shaft/ Through shaft |

|

Surface |

Smooth/ Cross line/ Center line/ Groove line |

|

Smoothness |

Ra6.3-0.4 |

|

Balancing |

G6.3/G2.5 |

|

O.D(mm) |

I.D(mm) |

Wall Thickness |

Stiffener |

|

Ф32 Ф33 Ф40 |

Ф24 Ф27 Ф34 |

4:00 3:00 3.00 |

8 |

|

Ф40.5 Ф42.5 serrated roller Ф43.8 |

Ф31 Ф30 Ф34.5 |

5.00 4.50 5.00 |

|

|

Ф47 Ф50.5 Ф51 with groove |

Ф40.8 Ф40.5 Ф38 |

3.00 5.00 6.50 |

8

6 |

|

Ф55 Ф58.5 Ф61 |

Ф46.5 Ф51.5 Ф51 |

4.50 3.50 4.90 |

6 8 6 |

|

Ф70 serrated roller Ф71 Ф71 |

Ф46 Ф63.2 Ф61 |

7.20 4.50 3.50 |

8 7 |

|

Ф74.5 Ф75.5 Ф80 |

Ф60 Ф66 Ф73 |

7.20 4.50 3.50 |

8 8 |

|

Ф81 Ф81 Ф80 |

Ф72.5 Ф71 Ф69 |

4.30 5.00 5.50 |

8 8 8 |

|

Ф90 Ф99 Ф101 |

Ф81 Ф90.5 Ф92 |

4.50 4.30 4.50 |

8 8 7 |

|

Ф101.5 Ф101 Ф101 |

Ф91.5 Ф89 Ф86.3 |

4.50 11.00 11.00 |

7 8 8 |

|

Ф111 Ф115 Ф116 |

Ф102 Ф93 Ф94 |

4.50 11.00 11.00 |

7 8 |

|

Ф120.5 Ф121.5 Ф130.5 |

Ф105.5 Ф111.5 Ф118 |

7.50 5.00 6.25 |

9 |

|

Ф140 Ф145 Ф151.5 |

Ф120 Ф123 Ф139.5 |

10.00 11.00 6.20 |

8 7 8 |

|

Ф151.5 Ф153 Ф162 |

Ф131.5 Ф121 Ф148 |

10.00 11.00 7.00 |

9 |

|

Ф184 Ф203 |

Ф168 Ф179 |

8.00 12.00 |

|

|

Ф150.5 Ф151 Ф200 Ф320 |

Ф136.5 Ф140 Ф186 Ф296 |

7.00 5.50 7.00 12.00 |

10 |

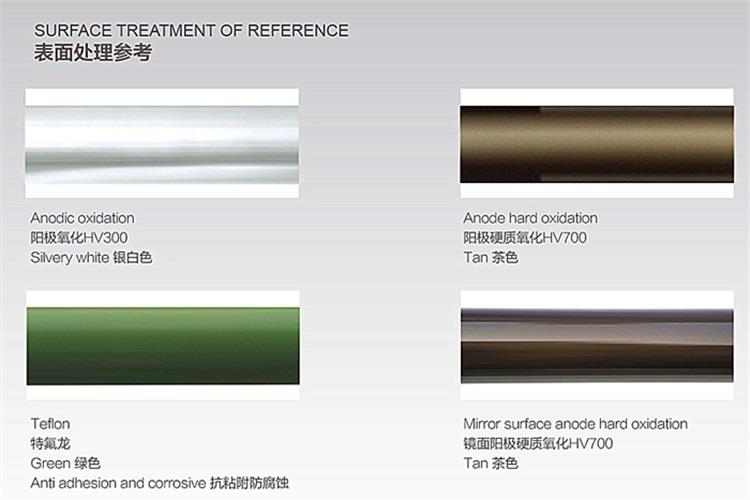

4.Surface treatment

We can also do special treatment on the aluminum roller surface which can realize good scratch resistance, abrasion resistance and anti-sticking performance.

01. Anodizing treatment HV300,the surface is silver.

02. Hard anodic oxidation treatment HV700,the surface is dark brown.

0.3 Teflon treatment,the surface is green.The roller is Anti-adhesion, anti-corrosion.

04. Mirror hard anodic oxidation treatment HV700 treatment, the surface is dark brown and has excellent mirror gloss.

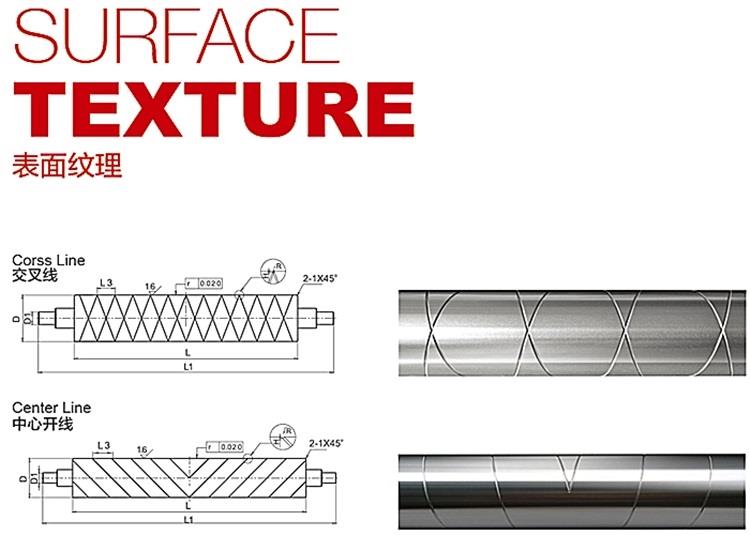

5. Surface texture and shaft type

1) According to shaft end model ,aluminum guide roller has 4 standard types: Flat tube type,Without-shaft type, Shaft type and Through-shaft type.

2)According to surface texture ,aluminum guide roller has 5 tandard types: Cross line type, Center line type, Grooved roller,anilox roller and Rolla roller.

Aluminum guide roll surface damage form

1, roll surface crack

Aluminum guide roller cracks are divided into normal cracks and abnormal cracks. Normal cracks are also called hot cracks. They are caused by the thermal stress generated by multiple temperature cycles, and the roll surface is gradually broken. It is a kind of micro-surface layer that occurs on the roll surface. Phenomenon; abnormal cracks are thermal shock cracks caused by accidents such as slippage, steel sticking, calendering, stacking steel, and tailing during rolling, and cracks of a certain depth and ductility are formed locally on the surface of the roll surface.

2, indentation

The aluminum guide roll indentation mainly refers to the intrusion of foreign matter such as iron oxide scale due to cleaning reasons during the production process, and irregular or irregularly shaped pits which are continuously or discontinuously distributed on the roll surface.

3, oxide film shedding

After the aluminum guide roll is rolled, after a period of hot roll, a thin layer of silver-gray or light-blue oxide film is formed on the surface of the roll, which is important for protecting the roll surface and improving the surface quality of the rolled piece due to the rolling force. The repeated action causes the oxide film to generate microcracks around the carbide; when the roll cooling capacity is insufficient, it is difficult to form a dense oxide film on the roll surface, and the oxide film is rapidly deteriorated even if it is formed. When the rolling is unreasonable, the oxide film is rapidly destroyed during the formation process, which causes the oxide film to fall off, leaving defects such as meteor spots on the roll surface, resulting in an increase in the roughness of the roll surface and an increase in the wear amount.

4, bonded steel, abnormal wear, etc.

Due to the abnormal rolling caused by the adhesion of the roll surface to the rolling stock, the aluminum guide roller has a sticking steel; the unreasonable process parameters during rolling cause excessive consumption of the same wide-kilometer roll, resulting in uneven wear on the roll surface.

Packing

Order Details

|

Item Name |

Aluminum Roller |

|

MOQ(Minimum Order Quantity) |

1PC |

|

Lead time |

10-15 days after receiving the deposit |

|

Calculated Weight |

Need to count |

|

Package |

Wooden Box/Pallet packing/according to clients’demand |

|

Price Term |

EXW,FOB, CIF, etc |

| Payment term | TT,L/C,Western Union |

| Country of Origin | China |

Hot Tags: aluminum alloy guide roller for printing machine, China, manufacturers, suppliers, factory, quotation, pricelist, buy