Brake Magnet

There are two types of magnetic powder clutches and brakes that are worthy of attention. There are two types of products: the coil rotary type and the coil static type. The coil rotary rotary coil is powered by a slip ring mounted on the shaft. This type of product is rarely used due to the...

There are two types of magnetic powder clutches and brakes that are worthy of attention. There are two types of products: the coil rotary type and the coil static type. The coil rotary rotary coil is powered by a slip ring mounted on the shaft. This type of product is rarely used due to the unreliable power supply method and the unbalance caused by the coil during high-speed rotation. Applications, most of the products on the market today use coil static type.

The coil stationary product has two types of housing stationary and housing rotating. For products where the housing is stationary, the stationary coil is located outside the rotor, and for products where the housing rotates, the stationary coil is located inside the rotor. Depending on the shape of the output rotor face, the commonly used products are cylindrical rotors, cup rotors and disc rotors. Cylindrical rotors are generally used in large and medium-sized products, and the structure is relatively simple; cup-shaped rotors are generally used for housing-rotating products, which have good heat dissipation and large slip power; and disc-shaped rotors are generally used for micro-products, which are suitable for precision control applications.

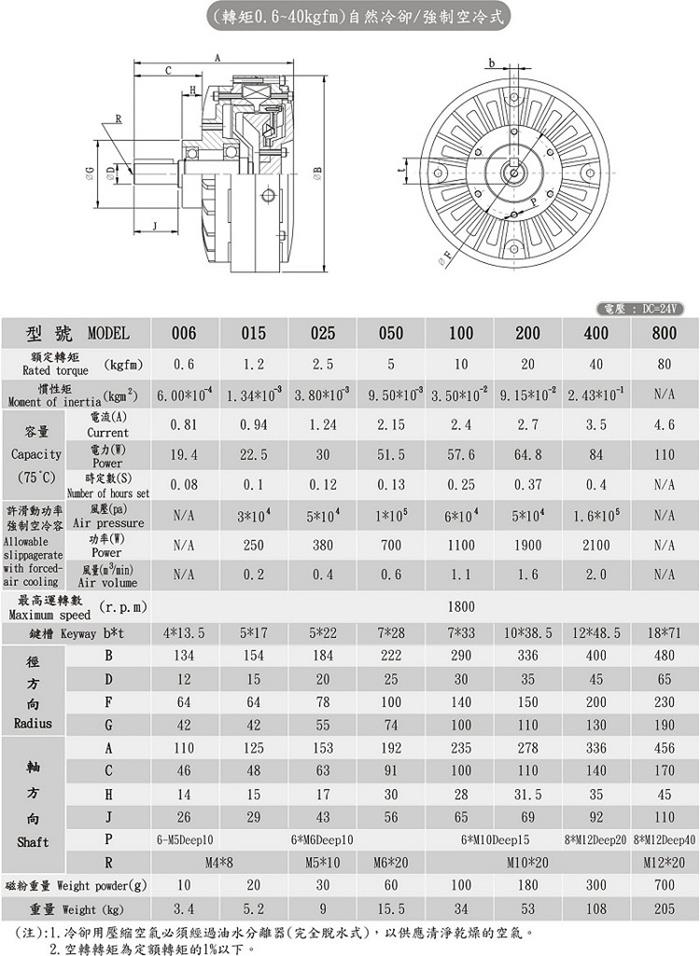

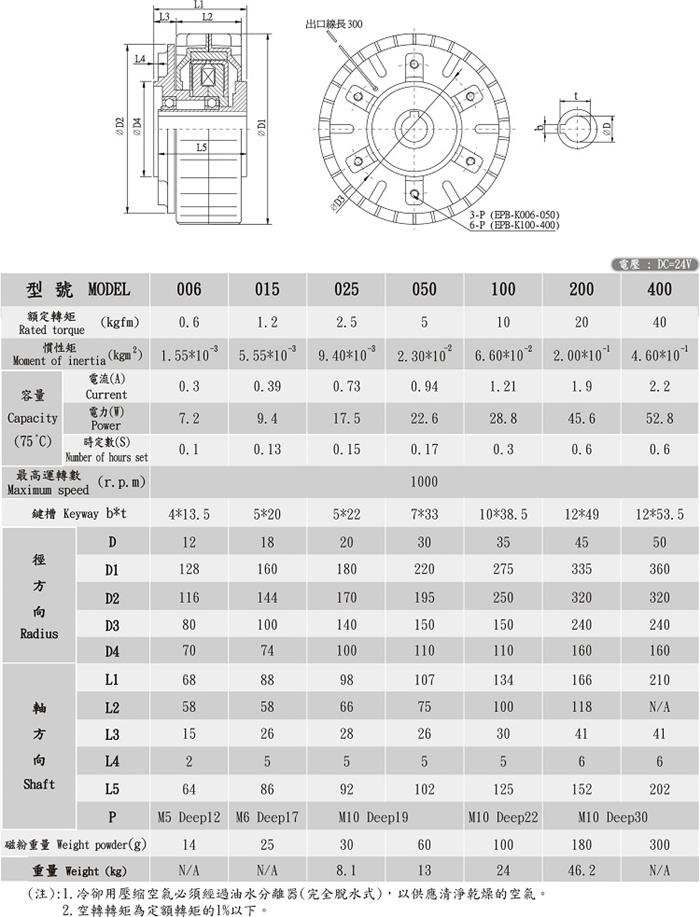

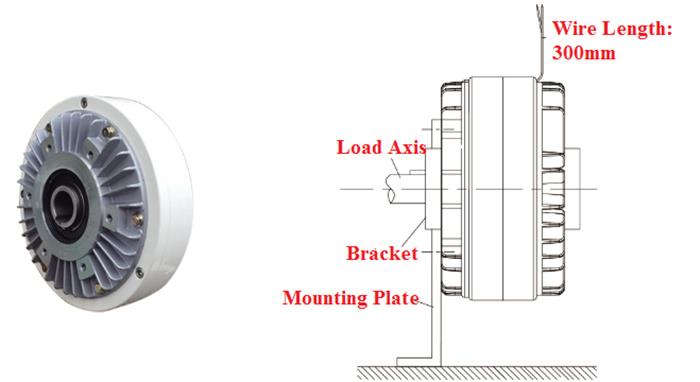

According to the specifications, it can be divided into large (%"""34" or above, medium and small (2-5""34/ and micro.#34//, according to its cooling method, it can be divided into natural cooling type, forced air cooling type and water. Cooling type, according to the connection type, can also be divided into extended shaft type and hollow shaft type. According to different main and driven transmission routes, it can be divided into housing rotation type and housing static type (coil stationary), and horizontal installation according to installation form. And vertical and so on. Various forms can be combined according to the needs of use to complete the corresponding functions, but the form of vertical and horizontal installation can not be used interchangeably.

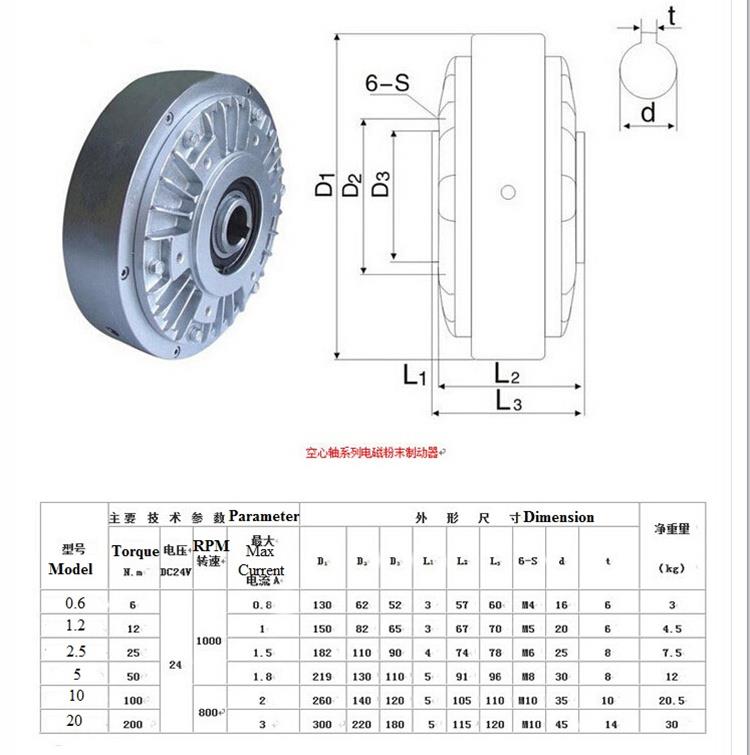

The magnetic powder brake has a minimum torque specification of 0.5Nm, a torque specification of 5Nm (including 5Nm), and a maximum magnetic torque of 400Nm, and 6Nm, 12Nm, 25Nm, 50Nm, 100Nm, and 200Nm are common specifications. The magnetic powder brake has a rated voltage of DC24V and can be controlled by a tension controller to output DC0~24V.

When selecting the magnetic powder brake, please select according to its installation type, rated torque, rated voltage, etc., to improve the selection efficiency:

1. Determine the details, such as the type, torque and type of the magnetic powder brake (internal rotating hollow shaft series, external rotating hollow shaft series, micro series, single shaft series);

2, the size or range of torque, the unit Nm, the common torque range is between 0.5Nm ~ 400Nm;

3. When ordering the magnetic powder brake or clutch, you should inform us which machine and use it is used for, so that our company can better recommend or suggest for users;

4. Before the magnetic powder brake and clutch are tested, please read the product manual carefully.

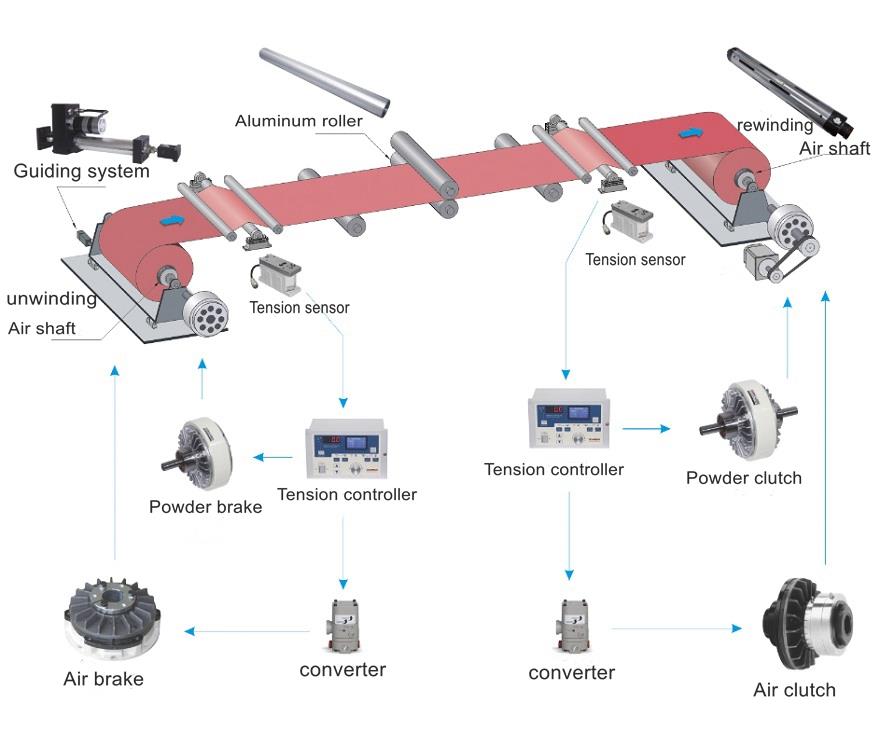

5, supporting products, POD magnetic powder brake, POC magnetic powder clutch can be used with tension controller, tension sensor, gear

Deceleration motor, air shaft and other products are available, please specify the supporting equipment, please tell us;

6, consumables - magnetic powder, if the user needs to be spare, please tell us the weight required, the unit is gram (g).

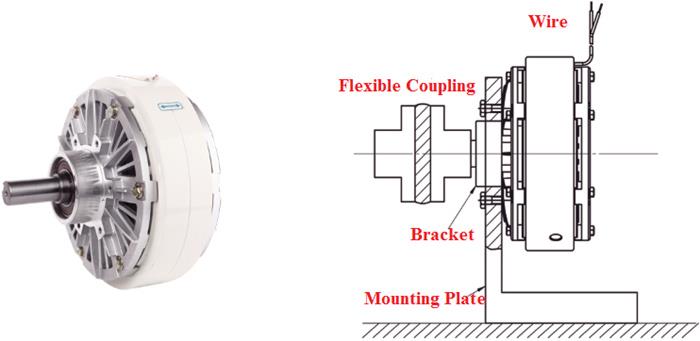

PRE-B Single Shaft Magnetic Powder Brake

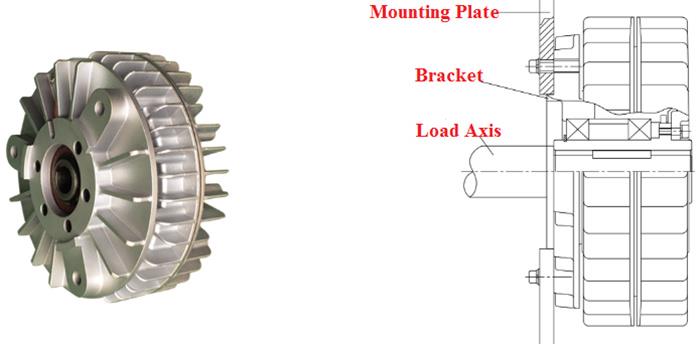

PRE-B1 Hollow Shaft Shell Rotating Magnetic Powder Brake

PRE-B2 Hollow Shaft Inner Shell Rotating Magnetic Powder Brake

Application of magnetic powder brakes in current technical requirements

A test method for a low voltage ride through capability of a frequency converter of a magnetic powder brake, characterized in that the steps include:

(1) Set the voltage sag generator to be connected between the factory bus and the inverter of the auxiliary machine, and the inverter of the auxiliary machine is AC output to the motor of the auxiliary machine, and the magnetic powder brake is connected to the output shaft of the motor under test. The circuit breaker Q0 and the circuit breaker Q1 are set between the factory bus and the voltage sag generator, the circuit breaker Q2 is set between the voltage sag generator and the inverter of the auxiliary machine, and the digital storage recorder is set, respectively connected AC input voltage terminal of the test auxiliary machine inverter, AC output voltage terminal, DC+

(2) Start the digital storage recorder, select the digital storage recorder channel and set the coupling mode and voltage upper and lower limit parameters;

(3) Close the circuit breaker Q0 and circuit breaker Q1 of the factory bus, so that the voltage sag generator is powered, the input voltage of the voltage sag generator and the three-phase indicator are normal. According to the voltage sag simulation, set the voltage. The sag time, the number of sag, and the corresponding circuit breaker outlet according to the sag voltage value;

(4) Close the circuit breaker Q2, check the AC input voltage of the digital storage recorder, and the DC bus voltage of the inverter is normal; (5) According to the local or remote control mode of the auxiliary machine of the tested auxiliary machine, set the starting frequency of the inverter, and start the inverter to check that the DC bus voltage and AC output voltage of the digital storage recorder are normal;

(5) According to the local or remote control mode of the auxiliary machine of the tested auxiliary machine, set the starting frequency of the inverter, and start the inverter to check that the DC bus voltage and AC output voltage of the digital storage recorder are normal;

(6) Gradually increase the excitation current of the magnetic powder brake, and monitor the AC input current of the inverter with a caliper meter until the input current increases to the input current when the inverter is in normal operation;

(7) Start the storage recording mode, click the suspend button on the voltage sag generator panel, simulate the voltage sag according to the voltage sag number, sag time and sag depth set in (3), at the end of the sag After the normal voltage is restored, the storage recording mode is ended;

(8) It can be judged whether the inverter of the auxiliary auxiliary machine has the low voltage ride-through capability required by the index by storing the change of the DC bus voltage and the AC output voltage of the auxiliary auxiliary machine during the voltage sag recorded by the recording.

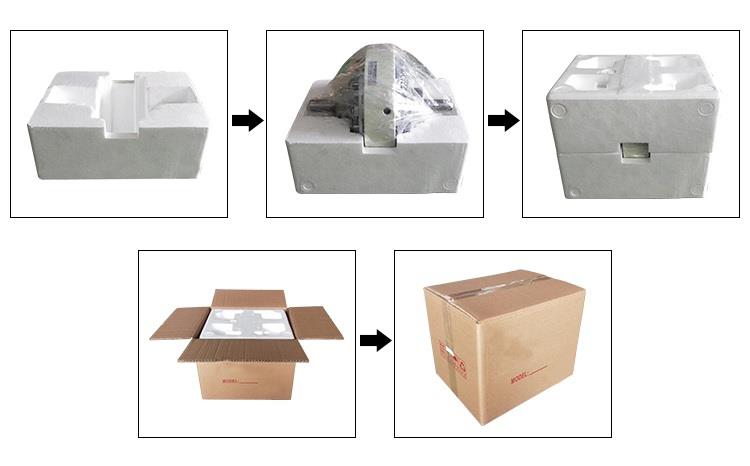

Packing

Order Details

Item Name | Magnetic Powder Brake |

MOQ(Minimum Order Quantity) | 1Pc |

Lead time | 3-5 days after receiving the deposit |

Calculated Weight | According to different models |

Package | Carton/Wooden Box |

Price Term | EXW,FOB, CIF, etc |

Payment term | TT,L/C,Western Union |

Country of Origin | China |

Hot Tags: brake magnet, China, manufacturers, suppliers, factory, quotation, pricelist, buy