Core Shaft

Characteristics of the air shaft in pneumatic brake What are the characteristics of the pneumatic shaft of the pneumatic brake? The characteristics of the splitter: it is a kind of special winding of the hair, the reel, the pneumatic brake can be inflated after the high pressure is inflated....

Characteristics of the air shaft in pneumatic brake

What are the characteristics of the pneumatic shaft of the pneumatic brake? The characteristics of the splitter: it is a kind of special winding of the hair, the reel, the pneumatic brake can be inflated after the high pressure is inflated.

Inflatable shaft features:

1. Inflatable operation time is short: the separation and placement of the inflation shaft and the paper tube can complete the inflation and deflation in just 3 seconds, and the part of the shaft end side can be loosely engaged with the paper tube.

2. Large load capacity: According to the actual needs of customers, the size of the shaft diameter can be determined, and the high-hardness steel is used to increase the bearing weight.

3. Simple maintenance: long use time: Although the mechanical part of the inflation shaft is a component, each part of its own structure has a fixed specification, which can be used interchangeably, making it easy to maintain.

Understand what causes the inflation shaft to wind up at a low speed

For the air-expansion shaft, the winding speed is low, and the air-conditioning pressure should be stopped, which affects the work efficiency, so that the shaft cannot be large and small at the same time. Slitting machines are one of the most important facilities for machine companies. The function and the difference between the function and the difference directly reflect the level of the product and the production efficiency.

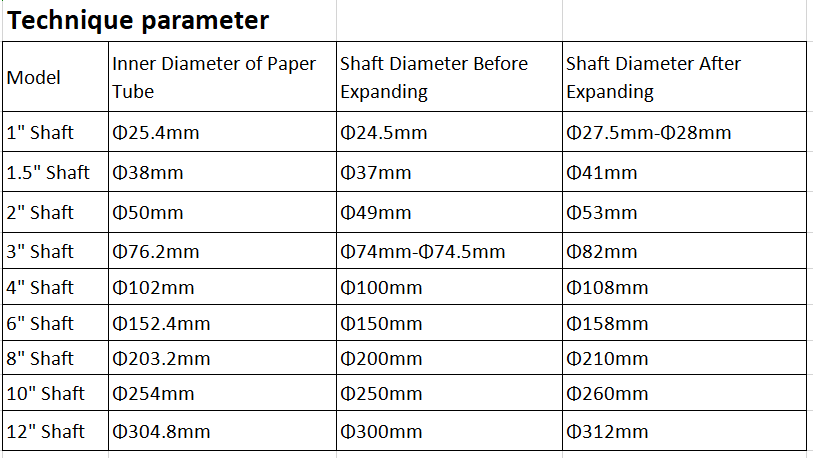

Wide range of applications: Inflatable shafts as individually designed parts, from 1 inch to 12 inches, the length and length are determined by the customer's actual needs, where there are strip printing, rewinding, coating, lamination, bag making, papermaking and other related volumes Take the machine. Can be applied to the company's inflatable shaft.

Cost-effective: The design of the inflation shaft is designed for practical work, and can be applied to thick and wide coils.

Long use time and simple maintenance: Although the inflation shaft is a mechanical accessory, each part in its own construction has fixed specifications and can be used interchangeably to make it easy to maintain. Our factory has strict requirements on the quality of the air-swelling shaft and the quality of the accessories. The quality of the products is absolutely guaranteed.

Single fitting: The inflatable shaft is a single part of the winding and unwinding machine. Each part in the structure has a fixed size and can be disassembled and combined to make maintenance easy and durable.

Air shaft freedom and machine tool motion

Any free object in three-dimensional space has six degrees of freedom, that is, movement in three directions along the X, Y, and Z axes and rolling in three directions of X, Y, and Z. At present, in the air-expansion shaft system, the machine tool spindle is used as the Z-axis, and the direction of the workpiece is taken as the positive direction.

Basic principles of machining

During the cutting process, the trajectory swept by the cutting tool relative to the part being machined is the contour shape that is machined. Whether the moving tool is still moving the workpiece, there must be relative motion between the tool and the workpiece to complete the machining process.

Processing range and number of control axes of the inflation shaft

CNC lathes are mainly used to machine rotary parts. Cutting tools only need to be used for lateral feed motion and longitudinal feed motion. Therefore, the CNC lathe only controls the X-axis and the Z-axis, and is a typical two-axis machine tool.

At present, most of the common air-inflating shafts are two-axis and half-machine tools. Although the machine tool can move in three directions of X, Y and Z, the control system can only control two axes at the same time for interpolation. Some inflatable shafts can The X and Y axes are linked, but the X and Y axes use a unified road signal for control. The control system still only outputs two signals, which is not a three-axis machine.

Although the two-axis and half-machine tools are capable of processing most of the parts, they still seem to have more than enough strength when machining some surfaces with higher precision requirements. Moreover, when the thread is milled on the air shaft, it is necessary to control the XYZ three axes at the same time. At this time, the two-axis and half-machine cannot be completed, and the non-three-axis machine cannot.

Three-axis machine tools still have the limitation of machining, that is, only one surface can be processed at a time. If other surfaces are to be processed, the workpiece should be re-clamped. One is the extra-spreading time, and the other is that re-assembly will bring errors. Therefore, on the basis of the three-expansion shaft machine, the rotation around the X-axis and the rotation around the Y-axis become four-axis and five-axis machines, but there is no six-axis machine. Since the Z-axis is the machine spindle, the spindle is supposed to rotate.

Order Details

Item Name | Core Shaft |

MOQ(Minimum Order Quantity) | 1Pc |

Lead time | 16-18 days after receiving the deposit |

Calculated Weight | Depend on dimension |

Package | Wooden Tube/Wooden Box |

Price Term | EXW,FOB, CIF, etc |

Payment term | TT,L/C,Western Union |

Country of Origin | China |

Hot Tags: core shaft, China, manufacturers, suppliers, factory, quotation, pricelist, buy