Great Pyramid Air Shafts

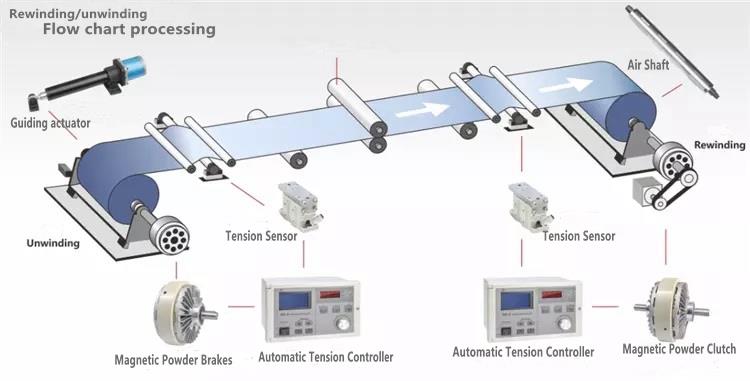

These Core Shaft ( Air Expandable Shaft ) are used for winding and unwinding operations in various industries such as plastic, paper & packaging, polyester, film, foil, rolling mills, tyre, textile process etc. Specifications: Body: Aluminium & M.S. Size: Shaft O.D. 3”/4”/6”/8”/12”...

These Core Shaft ( Air Expandable Shaft ) are used for winding

and unwinding operations in various industries such as plastic, paper

& packaging, polyester, film, foil, rolling mills, tyre, textile

process etc.

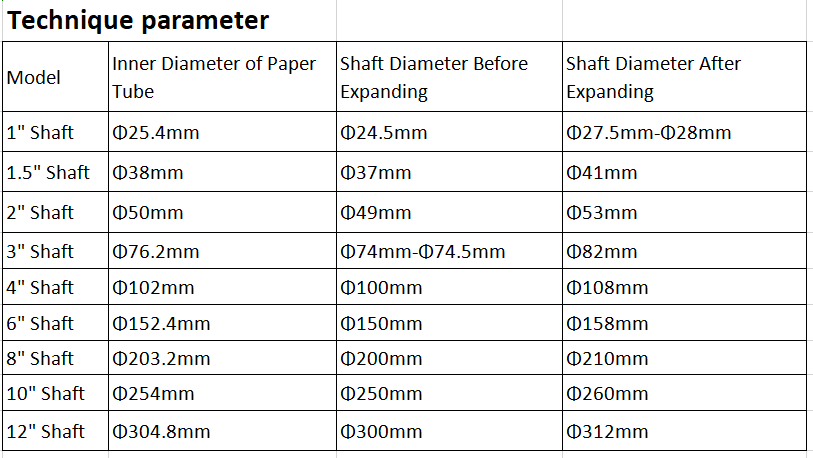

Specifications:

Body: Aluminium & M.S.

Size: Shaft O.D. 3”/4”/6”/8”/12”

Length: Up to 4000 mm

Performance indicators: Proven World Class 100% Customer Satisfaction Ratio

The use of the inflation shaft is very simple, that is, simply by clamping the tube to achieve the working state. The air-inflating shaft has a built-in airbag, and the air-filled expansion dies are used to wind up the unwinding product. When the work is completed, deflate the material die. The flat position of the inflation shaft needs to be straightened. Do not keep it inflated when not in use. At the same time, ensure the humidity of the air shaft to avoid the rust of the air shaft.

When using the air-expansion shaft, it is necessary to check the inflation shaft at all times, and find small problems in time to avoid causing greater losses. For example, if the screw is loose and tightened in time, the shaft head is loose and timely, and so on, etc., the air shaft needs to be kept in mind.

Gas rising shaft corona treatment is to change the surface energy of many substrates, making it easy to bond with printing inks, coating materials and adhesives. All substrates have good adhesion characteristics after some processing in the manufacturing process. .

Key strip type air rising shaft

Corona treatment is a post-treatment. It should be noted that corona treatment is not the only treatment that can change the surface energy of a substrate that can be used in the production of substrates. Other treatment methods include flame treatment and coating treatment, and the specific treatment method depends mainly on the structure of the substrate.

Many people believe that corona treatment roughens the surface of the substrate, making it easier to absorb printing inks and adhesives, but this view is denied by observations made using scanning electron microscopy.

The current popular theory holds that corona treatment rearranges the molecular structure of the substrate surface to produce more polar parts, which is conducive to the attachment of foreign objects.

The surface energy is measured in dyne, and all liquids and most substrates (except porous) can measure ten dyne values. In order for the printing ink to adhere well to the surface of the substrate, the dyne value of the substrate should be 10 dyne higher than the dyne value of all inks.

The surface energy of water-based inks is higher than the surface energy of solvent-based inks, so the substrate must also have a high surface cause value. Everything in nature has the characteristics of returning to the initial state, which paper products processors want to achieve. The higher the value, the faster the processing energy decays.

Therefore, when water-based inks are printed on films, metal foils and some papers, they should be treated twice before starting printing. When using a corona treatment device (matched properly) on the printing machine, the processing energy level of the film can be lengthened to the original. Energy level (or slightly higher).

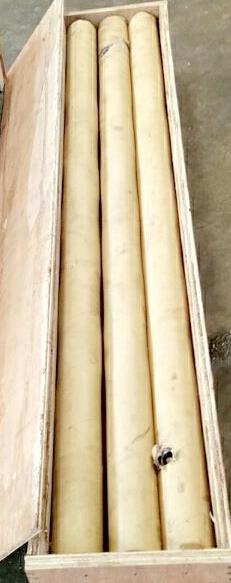

Packing

Order Details

Item Name | Air Expanding Shaft |

MOQ(Minimum Order Quantity) | 1Pc |

Lead time | 16-18 days after receiving the deposit |

Calculated Weight | Depend on account |

Package | Wooden Tube/Wooden Box |

Price Term | EXW,FOB, CIF, etc |

Payment term | TT,L/C,Western Union |

Country of Origin | China |

Hot Tags: great pyramid air shafts, China, manufacturers, suppliers, factory, quotation, pricelist, buy