Guide System

High-speed, high-precision, high-efficiency automated processing of coils requires ever-increasing control of the lateral position of the coil. Equipped with high-performance automatic rectification is the key to improving the production capacity and yield of coils. The coil will produce lateral...

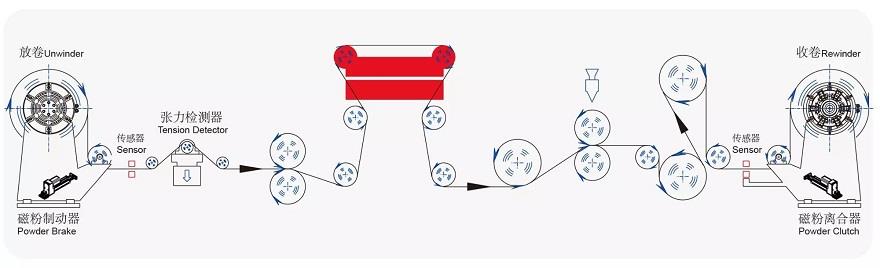

High-speed, high-precision, high-efficiency automated processing of coils requires ever-increasing control of the lateral position of the coil. Equipped with high-performance automatic rectification is the key to improving the production capacity and yield of coils. The coil will produce lateral displacement (running deviation) during the discharge, middle section and receiving process, so the correction system can be installed in the above three positions to control the precise passing of the coil.

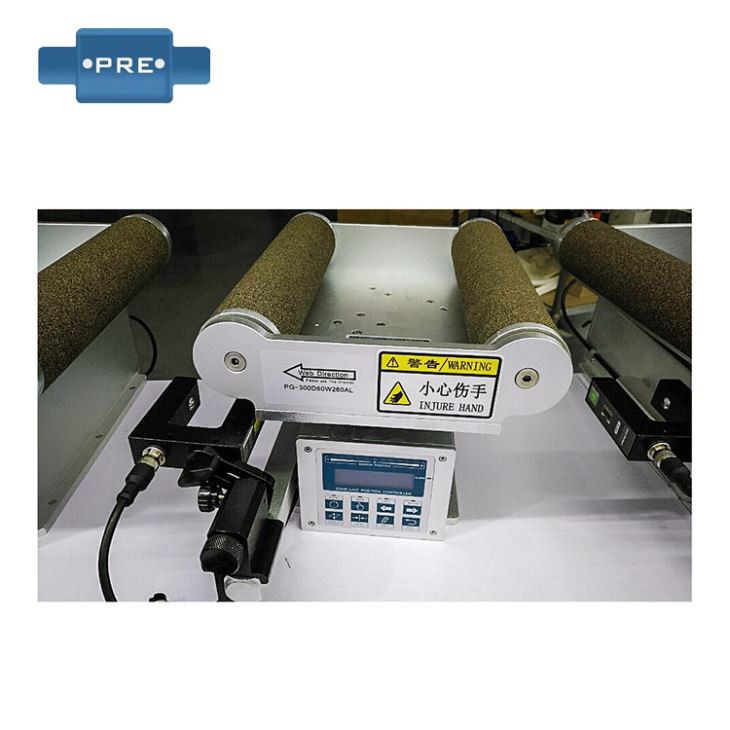

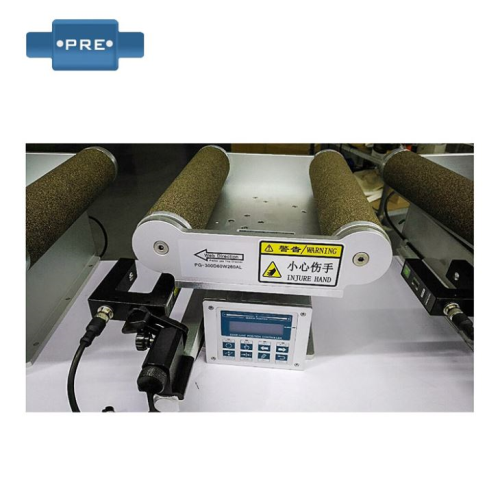

The guide system consists of an automatic control system consisting of a controller, an edge detection/detection line sensor, an electric drive, and a guiding mechanism. The guiding sensor detects the relative position of the edge, the line or the color block of the coil, converts it into an electric signal and transmits it to the correcting controller, and the guiding controller compares the signal with the set signal, and according to the deviation amount, the controller outputs a proportional proportional The signal is corrected immediately to the electric drive.

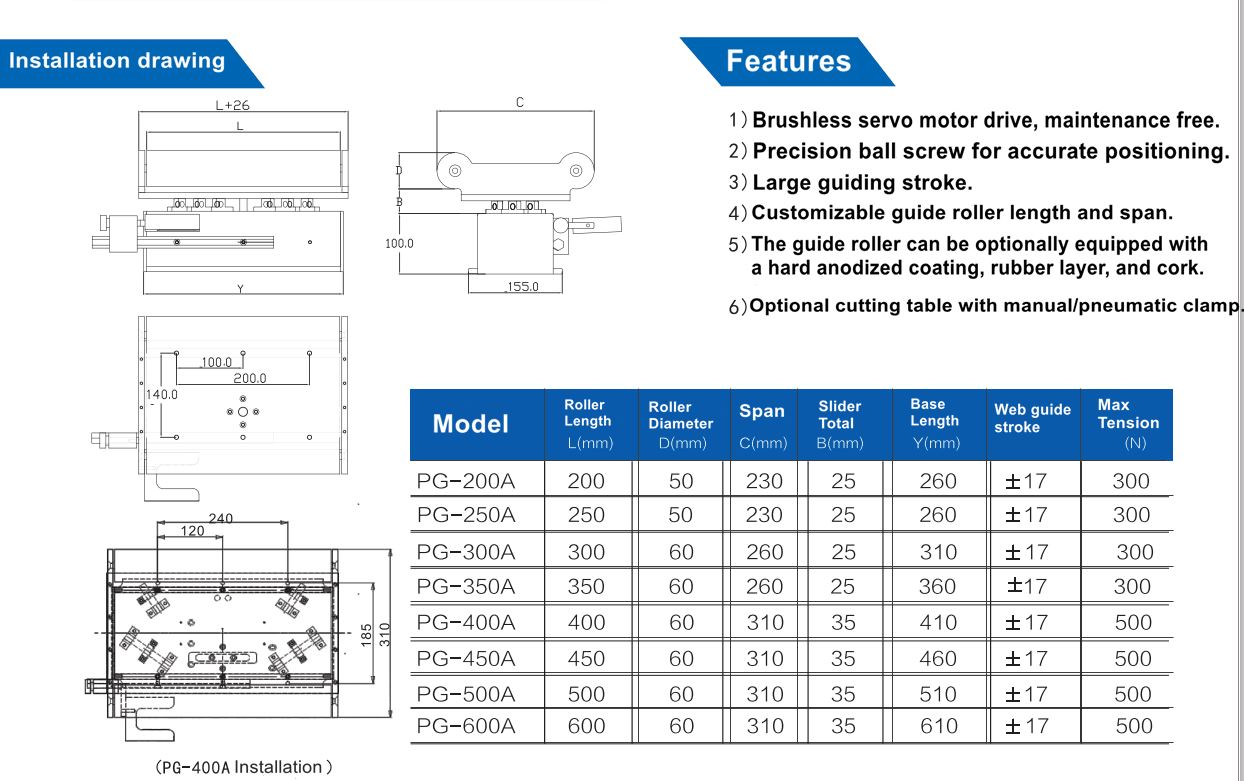

Featured features

1) One-piece design: tightly sealed, compact.

2) Powerful performance: perfect function and high precision.

3) Convenient operation: user-friendly interface design, LCD digital display.

4) Beautiful appearance: aluminum alloy finishing, surface sandblasting oxidation.

5) Flexible installation: can be integrated, separated and installed, can be installed at any angle.

The web guide control system is an automated closed-loop system that automatically corrects the lateral deviation of the coil. The working principle is as follows: the guiding sensor detects the relative position of the edge, the line or the color block of the coil, and compares the detected value with the set value to be converted into a proportional signal by the controller program for correction to the electric drive. The guiding control system is composed of a controller, an edge detecting/detecting line sensor, an electric drive, and a guiding mechanism. The system is divided into a rewinding and rewinding system and a traveling guide mechanism (customizable). The detection methods include edge detection, line inspection and alignment.

Applicable industries: printing, packaging, paper, non-woven, lithium batteries, solar energy, rubber tires, textiles, metallurgy, etc.

Applicable coil: Winding materials such as web, film, metal foil, film, leather, non-woven fabric, woven fabric, etc.

Applicable equipment

Printing and packaging: flexo printing machine, gravure printing machine, rotary printing machine, label printing machine, slitting machine, coating machine, laminating machine, inspection machine, die cutting machine, film blowing machine, bag making machine, etc.

Non-woven fabrics: sanitary cloth equipment, sanitary pad production line, baby diaper production line, medical auxiliary material production line, etc.

Lithium battery: pole piece coating machine, pole piece rolling mill, slitting machine, winding machine, etc.

Rubber tires: extruders, cord production lines, calenders, cutting machines, forming machines, etc.

Packing

Order Details

Item Name | Web Guide System |

MOQ(Minimum Order Quantity) | 1pc |

Lead time | 10-15 days after receiving the deposit |

Calculated Packing Size | Depend on model |

Package | Carton/Wooden Box |

Price Term | EXW,FOB, CIF, etc |

Payment term | TT, L/C,Western Union |

Country of Origin | China |

Hot Tags: guide system, China, manufacturers, suppliers, factory, quotation, pricelist, buy