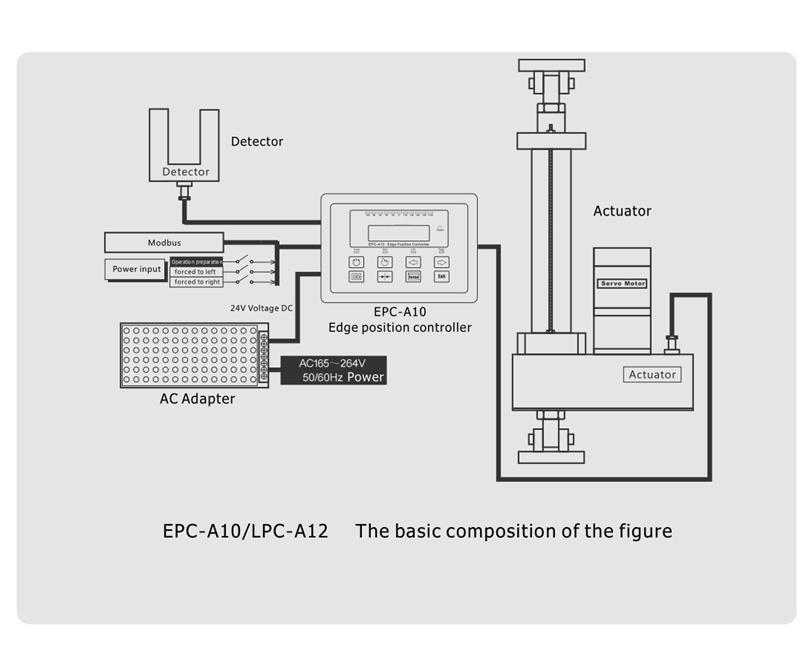

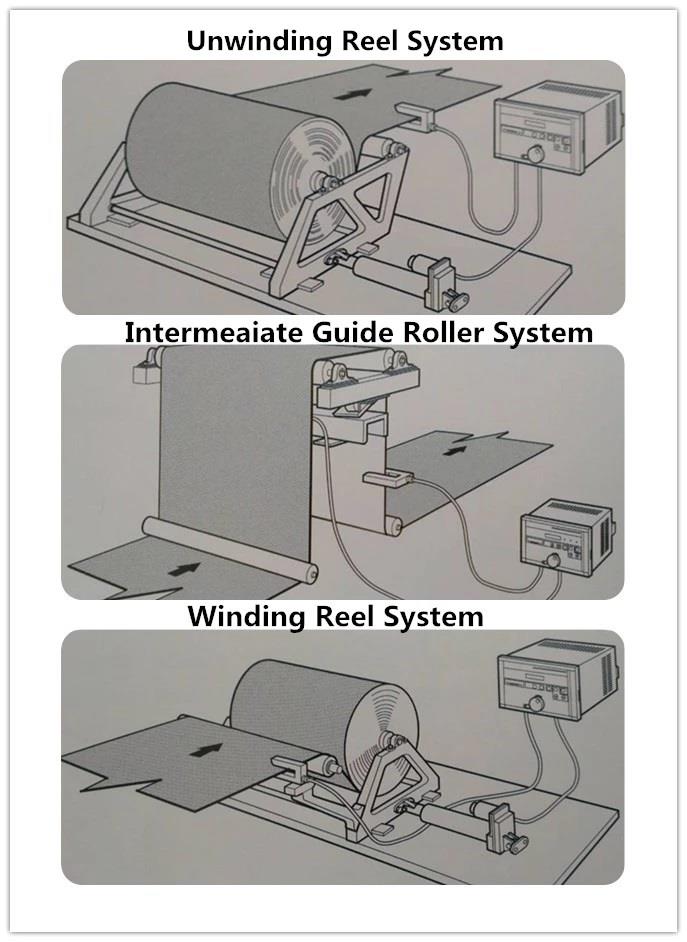

Edge Guiding System

The servo web guide controller EPC-A10 uses a high-speed 32-bit CPU to drive the DC servo motor. It adopts an over-adjusted integral variable PI adjustment algorithm with high precision of rectification, fast response, support for heel, heel and medium. 1. Support the chasing line, chasing the...

The servo web guide controller EPC-A10 uses a high-speed 32-bit CPU to drive the DC servo motor. It adopts an over-adjusted integral variable PI adjustment algorithm with high precision of rectification, fast response, support for heel, heel and medium.

1. Support the chasing line, chasing the edge, and working on the medium

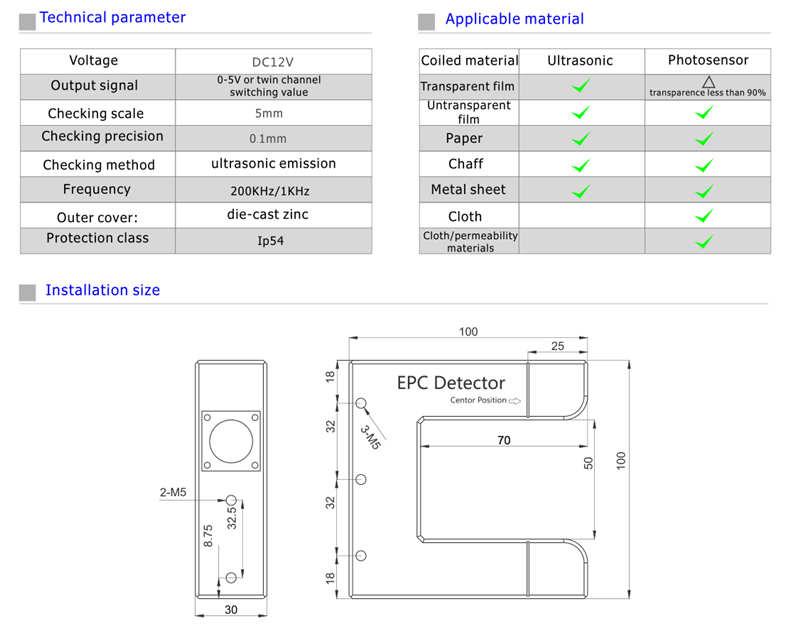

2, support photoelectric sensor, ultrasonic sensor

3, intelligent detection of sensor parameters, no need to calibrate the sensor in most environments

4, automatic stroke measurement, no mechanical limit switch

5, no overshoot integral variable PI adjustment algorithm, high precision, quick response, less error

6, ultra-high speed 500 microseconds (0.5 milliseconds) response speed

7, analog sensor signal 12-bit AD sampling, 700,000 times per second sampling speed

8, using FIR digital filter, hysteresis filter, anti-interference ability is stronger, the signal is more stable

9, DC servo motor pushes the ball screw

10, all system status parameters power-down memory.

Preparation and precautions before starting

a. Thoroughly check the mechanical seal, and whether the attachments and pipelines are installed properly and meet the technical requirements. b. Perform static pressure test before starting the mechanical seal to check whether the mechanical seal has leakage. If there are more leaks, you should find out the reasons and try to eliminate them.

If it is still invalid, it should be disassembled and reinstalled. Generally, the static pressure test pressure is 2~3 kg/cm2. c. Press the pump to turn the disc to check if it is light and even. If the car is struggling or not moving, check whether the assembly size is wrong and whether the installation is correct.

Reason.

Installation and outage issues

a. Keep the sealed chamber filled with liquid before starting. For transporting the solidified medium, steam is applied to heat the sealed chamber to melt the medium. start up

It is necessary to drive the car before to prevent the soft ring from breaking due to sudden start. b. For the mechanical seal using the pump external sealing system, the oil sealing system should be activated first. Finally stop the oil sealing system after parking. c. After the hot oil pump is stopped, the cooling water of the sealing oil chamber and the end face seal cannot be stopped immediately. When the oil temperature of the end seal is lowered to below 80 degrees,

To stop cooling water, so as not to damage the sealing parts.

Operational problem

a. If there is a slight leakage after the pump starts, it should be observed for a while. If the leakage is still not reduced if the operation is continued for 4 hours, the pump should be stopped.

. b. The operating pressure of the pump should be stable and the pressure fluctuation should be no more than 1 kg/cm 2 . c. During the operation of the pump, evacuation should be avoided to avoid dry friction and seal damage on the sealing surface. d. Sealing should be checked frequently. In operation, when the leakage exceeds the standard, the heavy oil is not more than 5 drops/min, and the light oil is not more than 10/min.

If there is still no improvement trend within 2-3 days, the pump plug should be stopped to check the sealing device.

Packaging:

Order Details

|

Item Name |

Web Guide system |

|

MOQ(Minimum Order Quantity) |

1Set |

|

Lead time |

2-3 days after receiving the deposit |

|

Calculated Packing Size |

Depend on actual model set |

|

Package |

Carton/Wooden Box |

|

Price Term |

EXW,FOB, CIF, etc |

|

Payment term |

TT, L/C,Western Union |

|

Country of Origin |

China |

Hot Tags: Edge Guiding System, China, manufacturers, suppliers, factory, quotation, pricelist, buy