Safety Chucks Manufacturers

Safety chuck, horizontal and vertical installation. The standard safety chuck is simple, practical and easy to install. It provides fast, safe, reliable and easy coupling and disconnection for frequent movements such as coupling and disengagement. Moreover, the dimensions of the safety chuck...

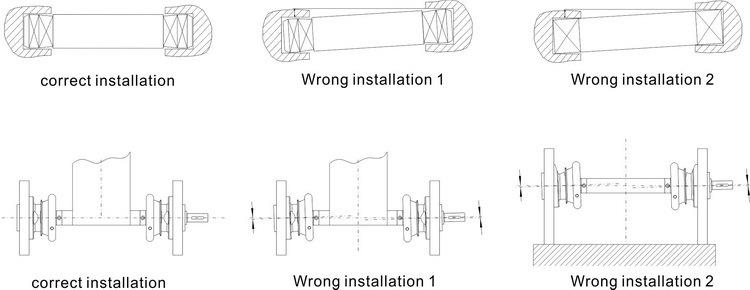

Safety chuck, horizontal and vertical installation. The standard safety chuck is simple, practical and easy to install. It provides fast, safe, reliable and easy coupling and disconnection for frequent movements such as coupling and disengagement. Moreover, the dimensions of the safety chuck drive section can be designed and manufactured according to different mechanical specifications and characteristics. The overall structure is safe and free of loose rotation. The sliding safety collet allows the operator to make axial adjustments during machine operation. Adjustment can be made by handwheel (optional), axial support bracket ensures safe and accurate torque transmission

Safety chuck basic function

The safety chuck is a quick-connecting device that is applied to the receiving and discharging reels to save time for the operator to load and unload. There is no need to move the structure of the machine every time when changing materials. The safety chuck provides the operator with the ability to quickly change materials when receiving and discharging. Reduce the time of the upper and lower materials, making the operator's work more efficient to achieve cost savings.

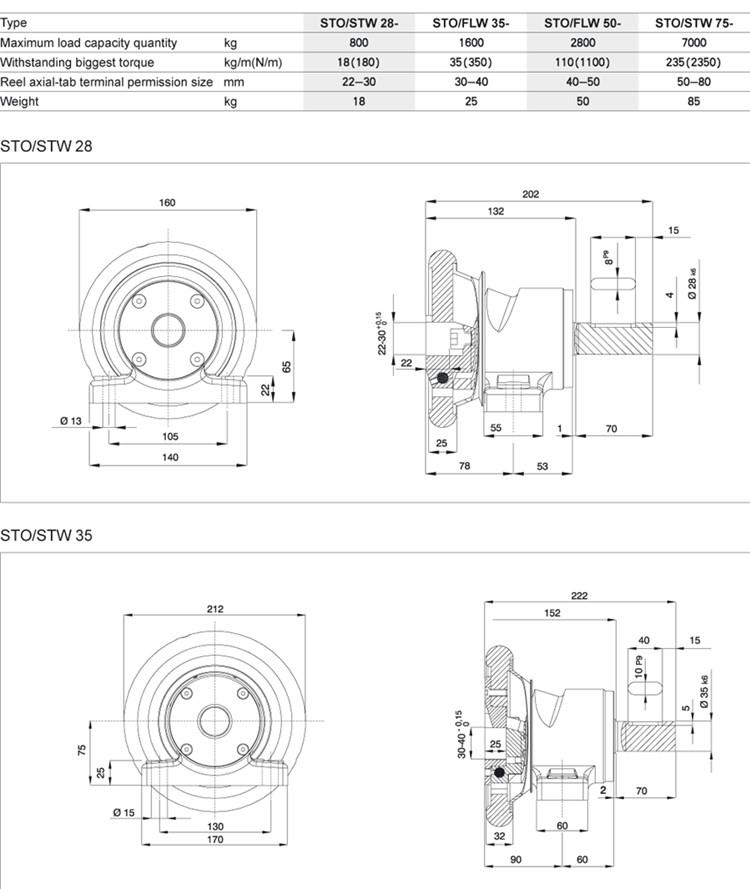

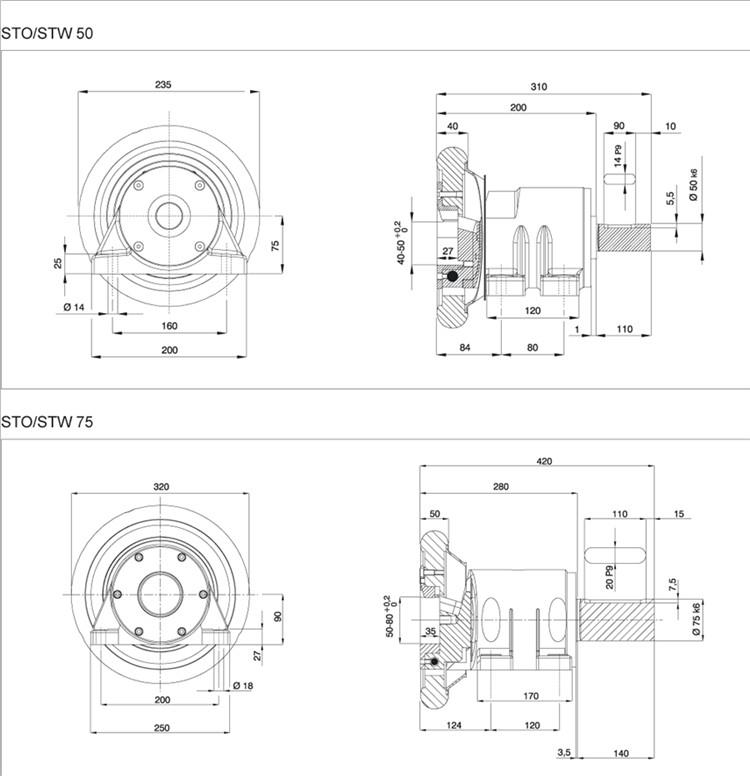

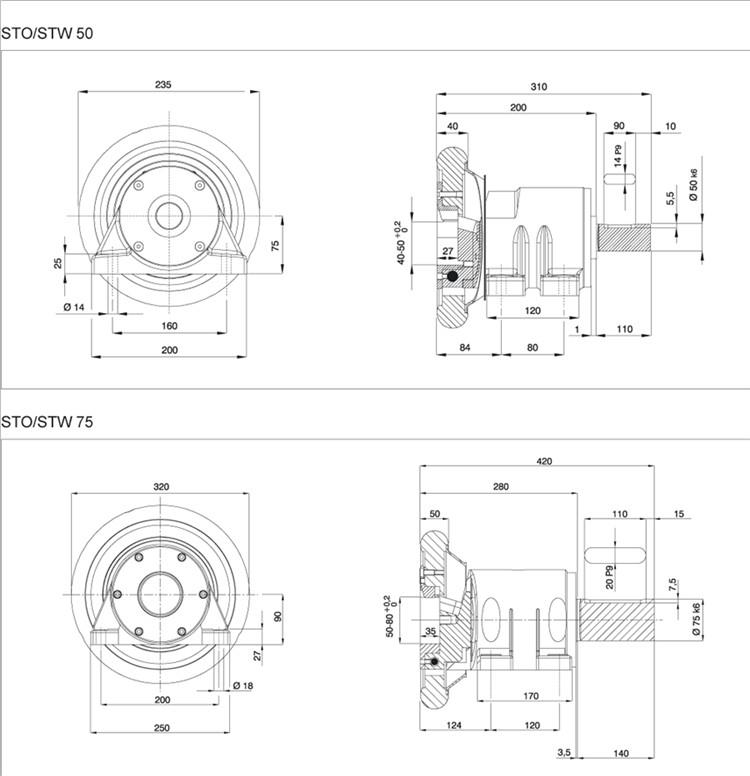

STOSTW Series Foot Mounted Safety Chuck

Foot Mounted Type Safety Chuck | ||||

Model | Max Load Weight(kg) | Resist Max Torque (kgfm) | Square Range(mm) | Weight(kg) |

STO/STW28 | 800 | 18 | 22mm-30mm | 18 |

STO/STW35 | 1600 | 35 | 30mm-40mm | 25 |

STO/STW50 | 2800 | 110 | 40mm-50mm | 50 |

STO/STW75 | 7000 | 235 | 50mm-80mm | 85 |

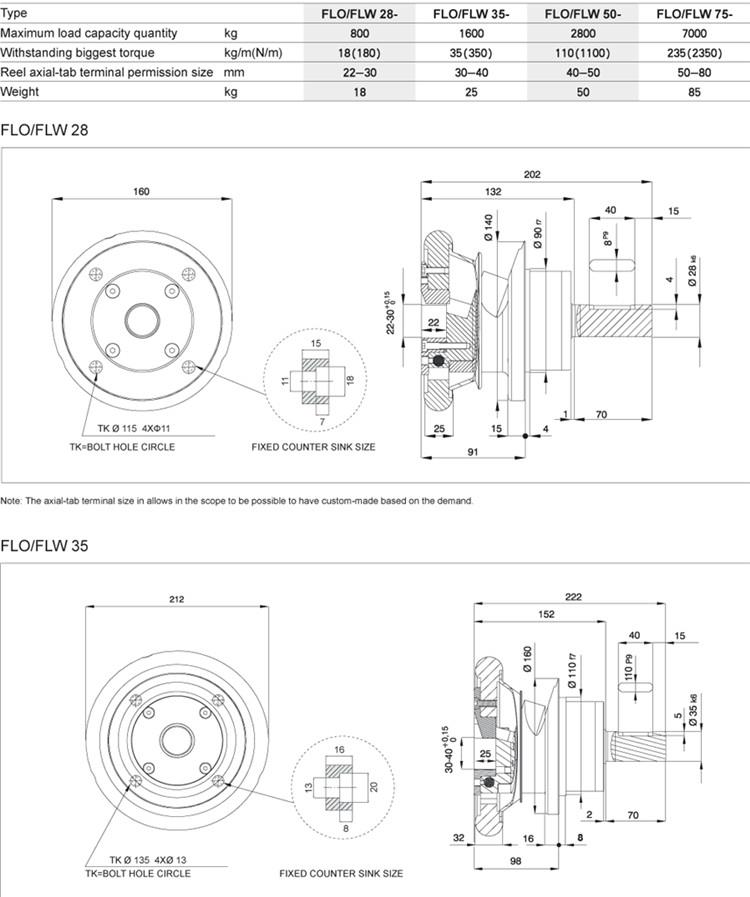

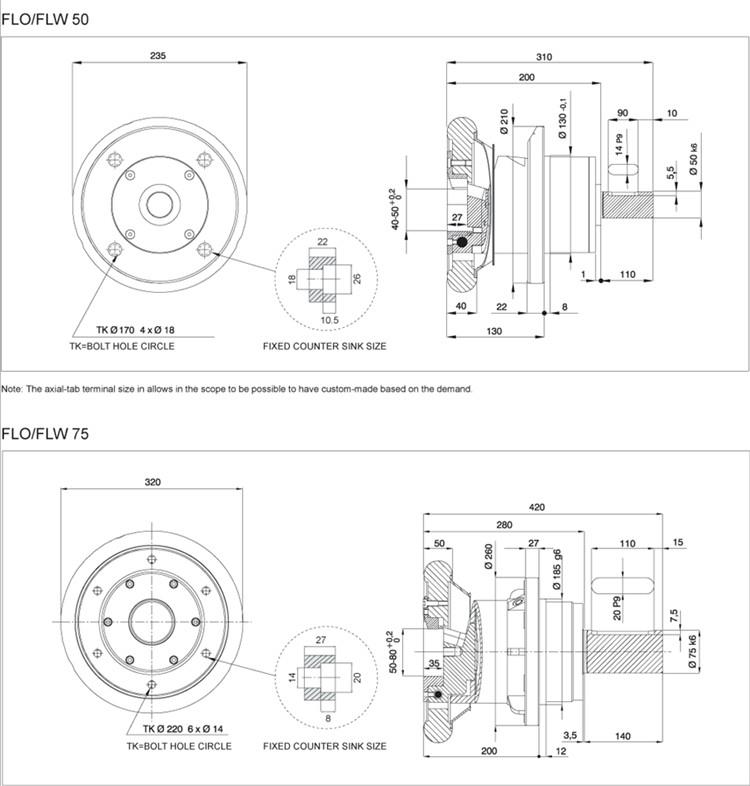

FLOFLW Series Flange Mounted Safety Chuck

Flange Mounted Type Safety Chuck | ||||

Model | Max Load Weight(kg) | Resist Max Torque (kgfm) | Square Range(mm) | Weight(kg) |

FLO/FLW28 | 800 | 18 | 22mm-30mm | 18 |

FLO/FLW35 | 1600 | 35 | 30mm-40mm | 25 |

FLO/FLW50 | 2800 | 110 | 40mm-50mm | 50 |

FLO/FLW75 | 7000 | 235 | 50mm-80mm | 85 |

Advantages of safety chucks

1. The overall structure of the safety chuck is reasonable, the rigidity is good, and it can withstand large torque and eliminate the looseness during rotation.

2, accurate machining accuracy to ensure accurate positioning, the reel nozzle uses a special heat treatment process;

3. Provide replaceable VT-type reel holders, which greatly extend the service life of the safety collet;

4, the use of special alloy steel materials with superior performance, superior durability and durability;

5. The bayonet is nickel-plated, and the bayonet is hardened and has high hardness and durability. It can ensure good performance even under heavy load and high speed applications.

6. The reasonable tolerance of the bayonet parts ensures smooth and continuous torque transmission, which greatly enhances the safety of the machine.

7. Simple installation, suitable for continuous sliding or high frequency use, buffer starting, with soft start characteristics.

The purpose of the safety chuck: It is suitable for the two ends of the square head air expansion shaft, which facilitates the disassembly and assembly of the air expansion shaft.

For machines that are used for winding and unwinding, the air-expansion shaft can be applied. The length of the air-expansion shaft can reach six meters or more, and the shortest can reach several hundred millimeters. The air expansion shaft is mainly suitable for post-press equipment such as: drying machine, flexo printing machine, gravure machine, trademark printing machine, etc.; other machinery: coating machine, leather machine, setting machine, embossing machine, slitting machine , rewinding machine, paper tube machine, bag making machine, laminating machine, laminating machine, film blowing machine, paper machine, setting machine, non-woven machine, cloth inspection machine, bronzing machine, battery equipment, etc. Use.

Safety chuck, horizontal and vertical installation. The standard safety chuck is simple, practical and easy to install. It provides fast, safe, reliable and easy coupling and disconnection for frequent movements such as coupling and disengagement. Moreover, the dimensions of the safety chuck drive section can be designed and manufactured according to different mechanical specifications and characteristics. The overall structure is safe and free of loose rotation. The sliding safety collet allows the operator to make axial adjustments during machine operation. Adjustments can be made with the handwheel (optional), which ensures that the crimping shaft is safe and accurately transmits torque.

Packing

Order Details

Item Name | Safety Chuck |

MOQ(Minimum Order Quantity) | 1Pair |

Lead time | 10 days after receiving the deposit |

Calculated Weight | According to different models |

Package | Wooden Box |

Price Term | EXW,FOB, CIF, etc |

Payment term | TT,L/C,Western Union |

Country of Origin | China |

Hot Tags: safety chucks manufacturers, China, manufacturers, suppliers, factory, quotation, pricelist, buy