Tension Control Products

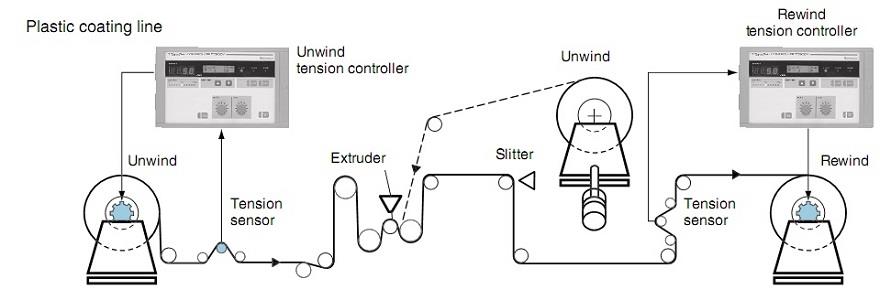

The tension controller is a widely used technology in the textile, paper and other industries. The quality achieved is directly related to the production efficiency and quality of the product. Most of the early tension control was realized by means of analog electronic devices, and the general...

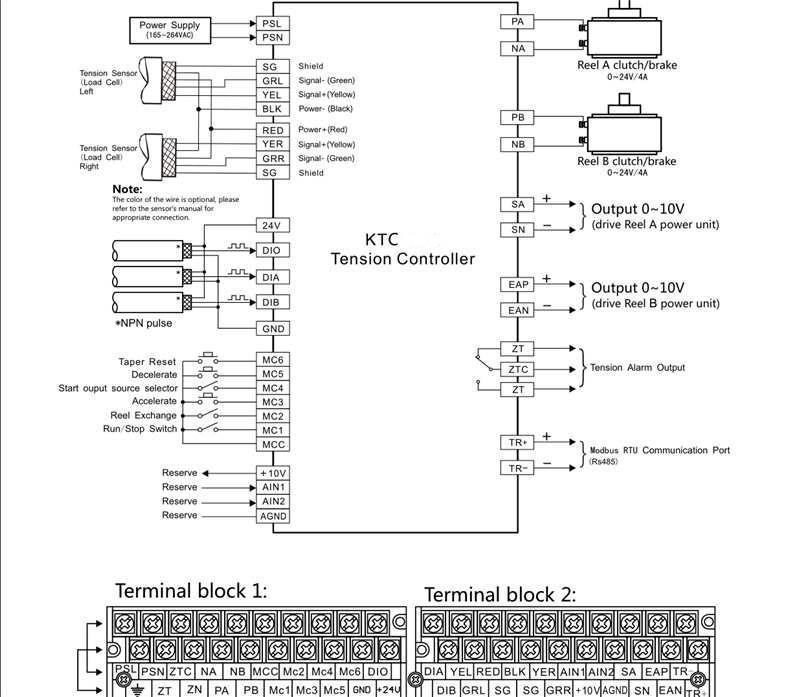

The tension controller is a widely used technology in the textile, paper and other industries. The quality achieved is directly related to the production efficiency and quality of the product. Most of the early tension control was realized by means of analog electronic devices, and the general control precision was low, the stability was poor, and the effect was poor. The step excitation method is used to identify the model of the controlled object, and the measurement of the actual parameters such as the winding diameter, paper thickness and moment of inertia is avoided. The tension controller can be designed only by the transfer function of the controlled object. Using the obtained controlled object transfer function, the incremental PID controller design is carried out in Simulink of Matlab, the PID parameters are determined, and the determined PID control parameters are used as the value area for the next genetic algorithm optimization. The results show that the modified objective function has a good effect on the optimization of genetic algorithm and provides a practical control strategy for constant tension control.

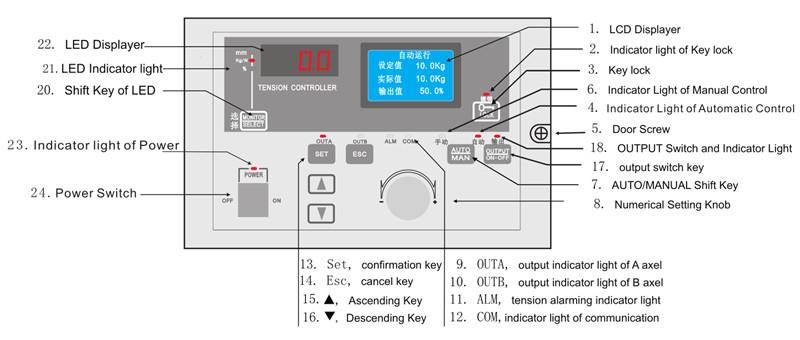

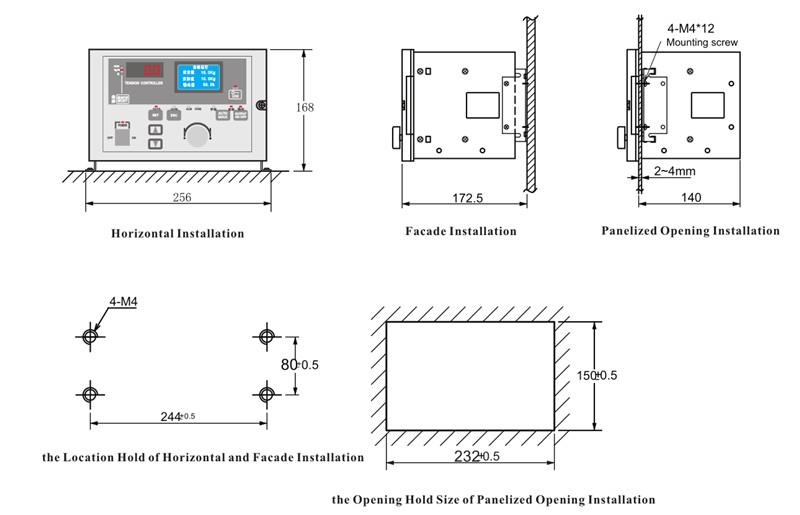

Operating Panel:

Installation:

The main role of the tension controller

Usually, when the machine is working, in order to ensure the speed of the machine, a tension controller is often used to control the running speed of the machine. This control must be effective for any speed of the machine, including acceleration, deceleration and constant speed of the machine. Even in the case of mechanical emergency braking, it should be able to ensure that the cut material is not damaged. The stability of tension control is directly related to the quality of the slitting product. If the tension is insufficient, the raw material will drift during operation, and the finished paper will wrinkle after slitting and rewinding; if the tension is too large, the raw material will be easily broken, so that the finished paper breaks after slitting and rewinding.

The main function of the tension controller: to achieve constant tension control of the coil, or to achieve taper control of the coil tension according to the process requirements. Tension controllers are generally used to control magnetic powder brakes, inverters, servo motors, etc. Under normal circumstances, there are many occasions requiring constant tension control; for taper control, it is generally applied in the case of winding, such as achieving tight inner ring of the coil and loose outer ring, so that the material is not easily deformed after being rolled up.

Order Details

Item Name | KTC-828A Automatic Tension Controller / KTC-818A Semi-Auto Tension Controller / KTC-838A Automatic Tension Controller with Taper and Communication |

MOQ(Minimum Order Quantity) | 1pc |

Lead time | 2 days after receiving the deposit |

Calculated Packing Size | 20cm*15cm*15cm,2kg/pc |

Package | Carton |

Price Term | EXW,FOB, CIF, etc |

Payment term | TT,L/C,Western Union |

Country of Origin | China |

Hot Tags: tension control products, China, manufacturers, suppliers, factory, quotation, pricelist, buy