Tension Measuring Device

The tension sensor is an instrument used to measure the tension value of the coil during tension control. Applications include pharmaceuticals, strain gauges, tensile strain gauges and compression strain gauges that are connected together in a bridge manner. When subjected to external pressure,...

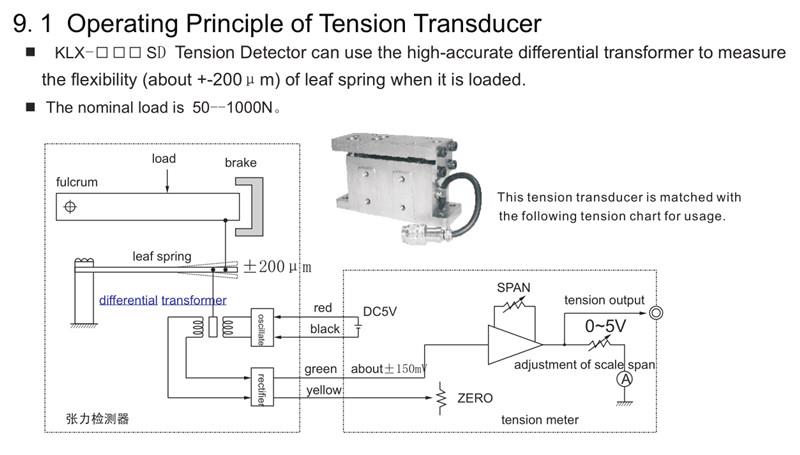

The tension sensor is an instrument used to measure the tension value of the coil during tension control. Applications include pharmaceuticals, strain gauges, tensile strain gauges and compression strain gauges that are connected together in a bridge manner. When subjected to external pressure, the resistance of the strain gauges changes. The amount of change will be proportional to the strain. The size of the tension; the micro-displacement type is to apply a load by an external force to cause the leaf spring to be displaced, and then the tension is detected by the differential transformer. Since the displacement of the leaf spring is extremely small, about ±200 μm, it is called a micro-displacement type tension detector. . In addition, it is divided into: the shaft top, the shaft type, the cantilever type and the like.

The LX series of tension sensors are tested with full bridge strain gauges and processed by integrated circuits. Therefore, the tension is detected, and the characteristics of low temperature floating, high temperature setting, and good linearity are obtained.

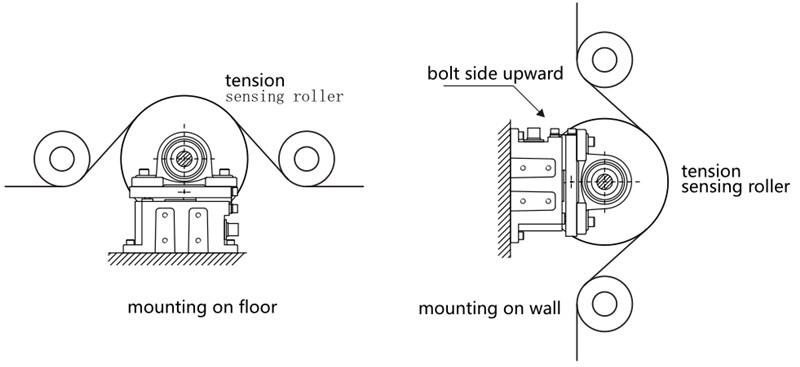

In order to ensure the accuracy of the tension sensor, there are still some problems in the process of installation and use. Please pay attention to the following details when installing and using the tension sensor to ensure the measurement accuracy and service life of the tension sensor:

1. The tension sensor should be handled lightly, especially for small-capacity sensors that use alloy aluminum as the elastomer. Any shock or drop caused by vibration is likely to cause a large output error.

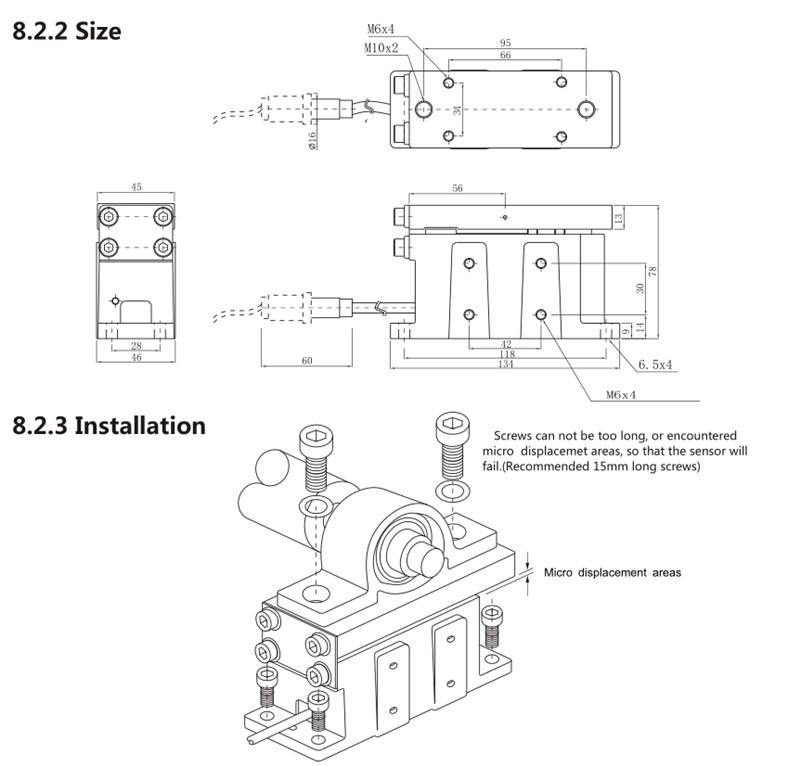

2. Design the loading device and the installation should ensure that the action line of the loading force coincides with the force axis of the tension sensor, so that the effects of the tilt load and the eccentric load are minimized.

3. In terms of level adjustment. If a single tension sensor is used, the mounting plane of the base should be adjusted to the level using a level; if multiple sensors are simultaneously measured, the mounting surface of the base should be kept at a level as much as possible. The main purpose is to ensure that each sensor is basically the same.

4. Determine the rated load of the sensor used according to the range selection of the tension sensor in its description.

5, the base mounting surface of the sensor should be as smooth and clean as possible, without any oil or film. The mounting base itself should have sufficient strength and rigidity and typically require strength and stiffness above the sensor itself.

6. The sensor case, protective cover and lead connector are sealed and the user is not allowed to open.

7, to prevent chemical corrosion. Vaseline should be used to apply the outer surface of the tension sensor during installation. Avoid using direct sunlight and dramatic changes in ambient temperature

8. If it is unavoidable, install protective or mitigation devices.

9. In order to prevent the large current from directly damaging the sensor body and damage the sensor, it is forbidden to perform the welding operation after the sensor is installed.

10. Add a bypass device made of copper braided wire at both ends of the tension sensor loading device.

11. The cable should not be lengthened by itself. When it is really necessary to lengthen, it should be soldered at the joint and add moisture-proof sealant.

12. It is best to use a number of baffles around the tension sensor to cover the sensor. The purpose of this is to prevent debris from falling into the moving part of the sensor and affecting its measurement accuracy.

13. The cable of the sensor should be away from the strong power supply line or the place with pulse wave. If it is unavoidable, the cable of the tension sensor should be inserted into the iron pipe separately, and the connection distance should be shortened as much as possible.

14. Determine the rated load of the sensor used according to the range of the tension sensor in the description. Although the tension sensor itself has a certain overload capacity, it should be avoided during installation and use. Sometimes overloading for a short period of time may also cause permanent damage to the sensor.

15. In the case of high precision use, the tension sensor and instrument should be used after preheating for 30 minutes.

16. The sensor should be placed in a dry, ventilated, non-corrosive atmosphere.

Order Details

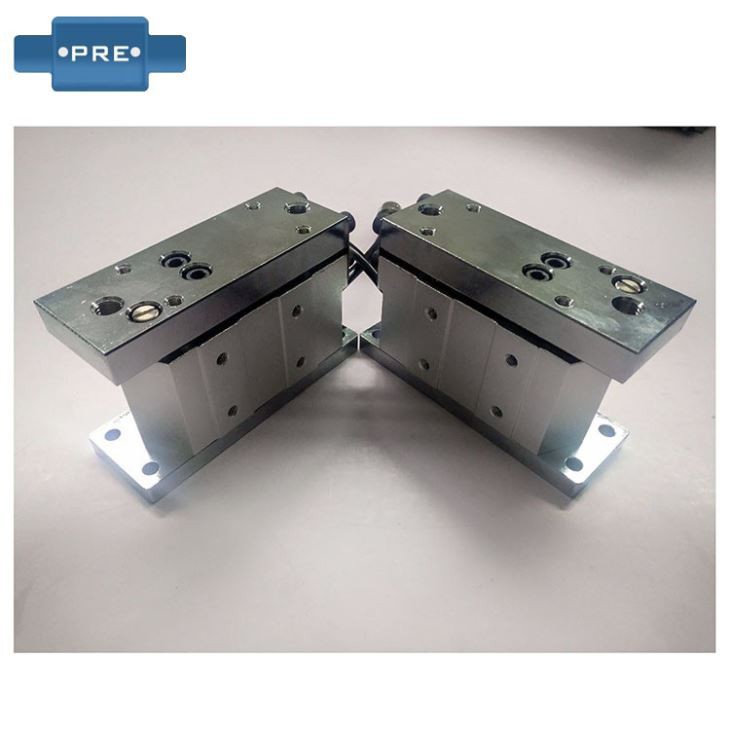

Item Name | LX Foot-Mounted Tension Sensor |

MOQ(Minimum Order Quantity) | 1Pair(2pcs) |

Lead time | 2 days after receiving the deposit |

Calculated Packing Size | 20cm*15cm*15cm,4kg/Pair/2pcs |

Package | Carton |

Price Term | EXW,FOB, CIF, etc |

Payment term | TT,L/C,Western Union |

Country of Origin | China |

Hot Tags: tension measuring device, China, manufacturers, suppliers, factory, quotation, pricelist, buy