Tile-type Air Shaft

Plate type air expansion shaft: also called plate type air expansion shaft, slat type air expansion shaft, tile type air expansion shaft, etc., but the working principle is the same. Features: The expansion part is a plate, usually the height of the expansion can reach 4mm to 5mm, such as the...

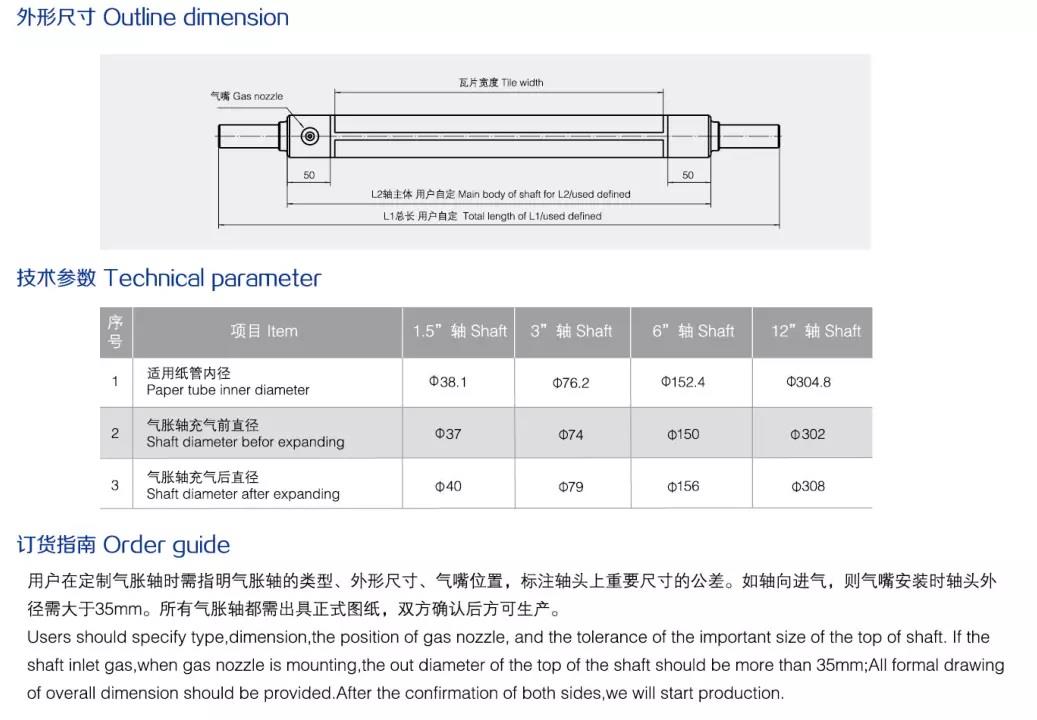

Plate type air expansion shaft: also called plate type air expansion shaft, slat type air expansion shaft, tile type air expansion shaft, etc., but the working principle is the same. Features: The expansion part is a plate, usually the height of the expansion can reach 4mm to 5mm, such as the diameter before expansion is 74mm to 75mm, the diameter after expansion can reach 78mm to 79m, special expansion height, separately required. 3-inch plate type air expansion shaft, usually using the inner diameter of the coil tube is 76mm. The plate type air expansion shaft expands from the whole plate, the fulcrum is evenly distributed, and the force is uniform. It can be used for mechanical or winding with higher precision. Light items, such as: electronic materials \ battery materials \ foam cotton \ plush \ paper towels \ non-woven \, etc., mainly based on actual needs.

use

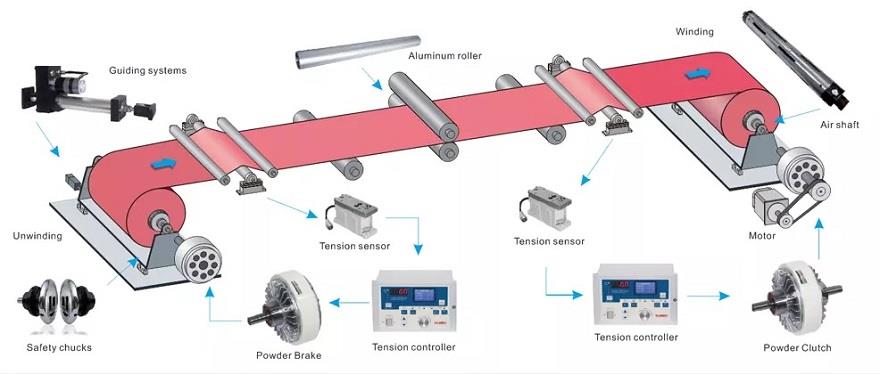

Applicable to the rewinding and unwinding of related machinery such as coating, slitting, printing, compounding, paper making, plastics, etc. It is especially suitable for the occasions where the paper tube has high roundness requirements or the use of the table rewinding and unwinding, which can effectively improve the work efficiency and products. quality. It adopts aluminum alloy tile, flexible expansion and contraction, high quality like rubber liner and fast filling and exhausting nozzle, good sealing effect and long service life; detachable shaft head for easy maintenance.

Tile type gas rise shaft features

★Adopting aluminum alloy tiles, flexible expansion and contraction;

★Equipped with high-quality rubber liner and fast filling and exhausting nozzle, the sealing effect is good and the service life is long;

★Removable shaft head for easy maintenance.

The slat-type air-expansion shaft centrifugal water film is convenient, high-efficiency, strong wear-resistance, durable, easy to operate and manage. It is widely used in boilers, but it is easy to solve problems with water slats. The part will gradually reduce the flow area of the flue ash collection, increase the resistance of the flue, and even lead to corrosion of the impeller ash and ash scale, resulting in dynamic imbalance, so shaking, from frequent replacement of the impeller, severely The alkali is lowered, causing the accident to be cut off. Therefore, the water problem of the water film to be solved is an important problem to maintain the safe and economic operation of the equipment and reduce environmental pollution.

The gray water passes through the water seal outlet to prevent the outside air from being inhaled, for example, the water seal is destroyed, and the gray water of the flue gas also reduces the slat type inflation shaft while the external air gray water is partially pulled in during operation. In the front, the reason for this is that there is not enough water to seal the liquid level. There are usually two types of spray and overflow in the water tube section. The overflow tank is divided into two or types of cylindrical outer casing types.

The injection pressure is insufficient or not sprayed so that the event does not exit the water tube wall, the water film cannot be formed, and the suspension is poured into a cylindrical shape with the flue gas being a slat-type inflation shaft. The nozzle is too small, the water film is unevenly divided, and there is no inner wall of the water film area, which reduces the effective area of the dust collection to achieve their efficiency. Sink outer tube type: lower the surface container so that the inlet portion is exposed on the surface, and then the ambient air will enter the tube together with the water instead of entering the water film along the tube wall, which not only affects the result, but also a large number of water droplets It is taken to the slat type air expansion shaft. This phenomenon is usually caused by the water supply being too small, the water pressure being unstable or the cross-sectional area of the inlet being too large.

To solve these problems, the following methods need to be taken: increase the water supply, but not so much waste; increase the high water storage tank, the water from the water tank to the overflow tank regulator; as far as possible at the same level, so as to overflow the balanced construction period; The average cross-sectional area of each inlet, the role of the inner wall of the barrel, should ensure that a sufficient amount of water forms a water film. Due to the influent water of the damaged water film, the water tank can be raised by the height of the outer edge of the ring, thereby increasing the level of the seal.

The reason is that water film and water slat type inflatable shaft, sometimes many boilers. In short, to improve the water supply, the well water film is formed, the main process of the space is properly separated, after the water treatment, the water film is a certain cross-sectional dimension and cross-sectional height of the slat-type inflation shaft, ensuring repeated observation, measurement, Calculate and test to achieve better results.

Paking

Order Details

Item Name | Tile-type /leafType Differential Air Shaft |

MOQ(Minimum Order Quantity) | 1Pc |

Lead time | 15-18 days after receiving the deposit |

Calculated Weight | Depend on dimension |

Package | Wooden Box |

Price Term | EXW,FOB, CIF, etc |

Payment term | TT,L/C,Western Union |

Country of Origin | China |

Hot Tags: tile-type air shaft, China, manufacturers, suppliers, factory, quotation, pricelist, buy