Web Tension

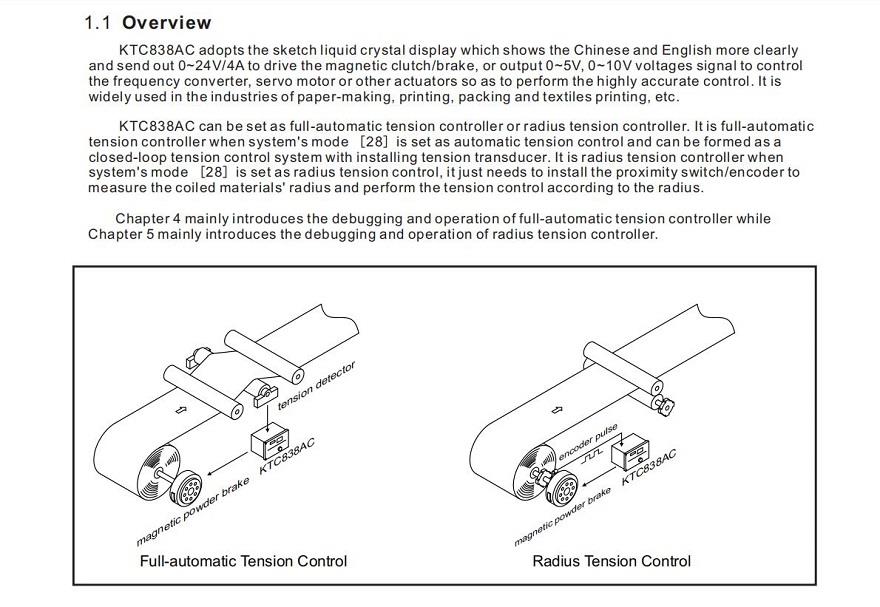

Tension open loop control in torque mode In the torque mode, a more stable tension control effect can be obtained without the tension detecting feedback device, and the structure is simple and the effect is good. However, the inverter needs to work in the closed-loop vector control mode, and the...

Tension open loop control in torque mode

In the torque mode, a more stable tension control effect can be obtained without the tension detecting feedback device, and the structure is simple and the effect is good. However, the inverter needs to work in the closed-loop vector control mode, and the speed measuring motor or encoder must be installed to make accurate measurement feedback on the motor speed.

The formula for calculating the torque is as follows: T=(F×D)/(2×i) where: T Inverter output torque command F Tension setting command i Mechanical transmission ratio D Reel diameter

After the torque of the motor is calculated, it can be used to control the current loop of the inverter, and the output torque of the motor can be controlled. The torque calculation is very important. This kind of control is often used in situations where the tension accuracy is not high.

Second, the tension closed-loop control in torque mode

The tension closed-loop control is based on the tension open-loop control and the tension feedback closed-loop adjustment is added. The tension detection signal is fed back by the tension detecting device and the tension setting value constitutes the PID closed-loop adjustment, and the inverter output torque command is adjusted to obtain higher tension control accuracy. The tension calculation is the same as the open loop control. Regardless of whether the tension open loop mode or the closed loop mode is used, additional torque is required to overcome the moment of inertia of the entire system during system acceleration and deceleration. If no compensation is applied, the tension will be small when the winding process is accelerated, the tension will be too large during deceleration, the tension will be too large when the unwinding process is accelerated, and the tension will be small when decelerating. The tension closed-loop control mode in the torque mode is often used in the case of paper and textile, etc.

The winding diameter calculation requires the winding diameter of the reel in all modes. During the production process, the winding diameter of the unwinding machine is constantly decreasing, and the winding diameter of the reeling machine is constantly increasing, that is, the torque must be Stable tension control can be obtained as the roll diameter changes. How important is the roll diameter calculation of the reel.

There are two ways to calculate the winding diameter: one is to directly transfer the calculated winding diameter to the inverter through the outside, which is generally obtained by calculation in the PLC. The other is obtained by the inverter itself. The vector control inverter has the winding diameter calculation function. In most applications, it is obtained by the inverter itself. This can reduce the complexity of the PLC program and the difficulty of debugging and reduce costs.

Tension control frequency conversion winding process requirements

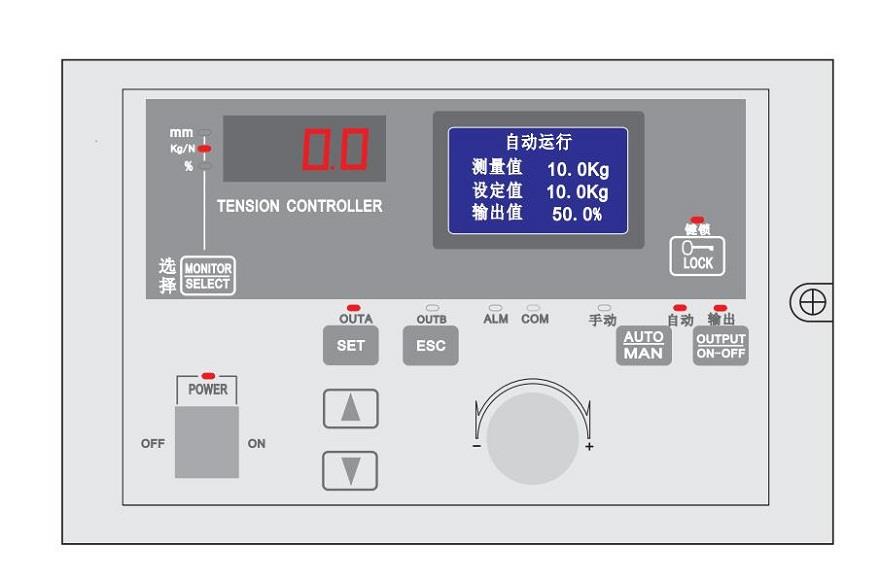

A constant tension is maintained throughout the winding process. The unit of the tension controller is: Newton or kilogram force.

When starting a small roll, the yarn cannot be broken due to excessive tension; the large roll cannot be loosened when it is started.

The above situation cannot occur in the state of acceleration, deceleration, and stop.

It is required to quantify the tension, that is, the magnitude of the tension (unit of force) can be set, and the actual diameter of the coil can be displayed.

Tension control frequency conversion winding advantages

1. Tension control The tension setting of the frequency conversion winding is set on the man-machine. The humanized operation is performed in units of force: Newton.

2, the use of advanced control algorithms: recursive operation of the winding diameter; the linear increment of the tension when the hollow coil diameter is activated; the application of the tension taper calculation formula; the dynamic adjustment of the torque compensation and so on.

3, the real-time calculation of the winding diameter, the accuracy is very high, to ensure the smooth performance of the winding motor output torque, and the recursive operation of the winding diameter is added when calculating the winding diameter, and the winding diameter can be corrected by itself when the operation is wrong. Go to the correct value.

4. Since the moment of inertia of the winding device is large, the winding diameter becomes small from small to large. If the operator accelerates, decelerates, stops, and reactivates, it is easy to cause the phenomenon of yarn explosion and loose yarn, which will directly lead to the quality of the yarn. After the transformation of the frequency conversion winding, the winding is stable and the tension is always constant. . Moreover, through the processing of the PLC, in the specific dynamic process, some dynamic adjustment measures are added to make the performance of the winding better.

5, on the basis of the traditional mechanical transmission winding to transform into a frequency conversion winding, very simple and low cost, basically do not need to transform the original machinery. The transformation period is small, and it can be installed and debugged basically in two or three days.

6. Overcoming the disadvantages of mechanical winding on mechanical wear and prolonging the service life of the tension control instrument.

Tension control concept

Tension control is to control how much force the motor outputs, that is, how many Newtons are output, and the motor shaft can control the output torque of the motor.

The true tension control is different from the system that forms the tension by the speed difference between the two power points. The essence of adjusting the tension by the speed difference is the PID control of the tension, the tension sensor is added, and the size, volume, start, stop, acceleration The adjustment during deceleration and parking is impossible to achieve the effect of true tension control, and the tension is not very stable. It will definitely affect the quality of the tension controller produced.

The essence of frequency conversion winding is to complete the tension control, that is, to control the running current of the motor, because the output torque of the three-phase asynchronous motor is T=CmφmIa, which is proportional to the current. And when the load is abrupt, it can ensure that the mechanical characteristic curve of the motor is relatively hard. Therefore, the vector inverter must be used, and the encoder infinite loop control must be added.

Application

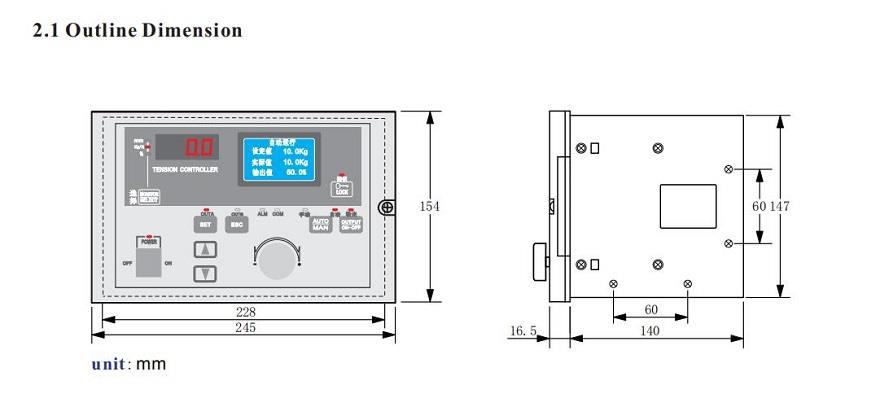

Order Details

Item Name | Automatic Web Tension Controller |

MOQ(Minimum Order Quantity) | 1pc |

Lead time | 1-2 days after receiving the deposit |

Calculated Packing Size | 15cm*10cm*10cm |

Package | Carton/Wooden Box |

Price Term | EXW,FOB, CIF, etc |

Payment term | TT, L/C,Western Union |

Country of Origin | China |

Hot Tags: web tension, China, manufacturers, suppliers, factory, quotation, pricelist, buy