Air In Bladder

The manufacturer of the inflatable shaft airbag liner simultaneously winds the intermediate rubber sheet between each two layers of copper-plated steel wire or copper-plated steel wire rope in a winding machine or a knitting machine, and the wire is wound at the beginning and at the end (some...

The manufacturer of the inflatable shaft airbag liner simultaneously winds the intermediate rubber sheet between each two layers of copper-plated steel wire or copper-plated steel wire rope in a winding machine or a knitting machine, and the wire is wound at the beginning and at the end (some early winding machines need to be plated in advance). Copper wire is prestressed and shaped).

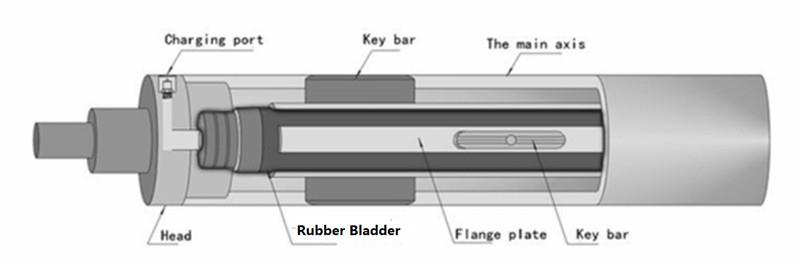

Facilitate the disassembly and assembly of the inflatable shaft, the air enters the airbag to cause air expansion, and has various structural forms, internal structural drawings of the inflatable shaft, such as the use of other inner diameter paper cores. When running unloading, it is suitable for torsion and mechanical winding. The new sliding air shaft is used as the main component of the slitting machine to complete the slitting of various materials. If it is encountered during the winding process When the material thickness is uneven and the machine tension control is unstable, the natural fragmentation operation of the inflation axis depends on the inherent fragile nature of the uniform metal shell under extremely high stress deformation to form a good distribution of fragment size and speed. The gas-increasing shaft of the production has always been the product of some old customers, specializing in the production of slip-swelling shaft sliding air shaft.

Specifications

ID*OD*Wall Thickness(mm) | Length(Meter/Circle) | ID*OD*Wall Thickness(mm) | Length(Meter/Circle) |

6*10*2 | 100Meters/Circle | 42*50*4 | 40Meters/Circle |

6*12*3 | 100Meters/Circle | 42*51*4.5 | 40Meters/Circle |

7*12*2.5 | 100Meters/Circle | 42*52*5 | 40Meters/Circle |

9*13*2 | 40Meters/Circle | 44*54*5 | 40Meters/Circle |

9*15*3 | 40Meters/Circle | 45*55*5 | 40Meters/Circle |

11*16*2.5 | 40Meters/Circle | 48*58*5 | 40Meters/Circle |

11&17*3 | 40Meters/Circle | 48*59*5.5 | 40Meters/Circle |

11*18*3.5 | 40Meters/Circle | 51*61*5 | 40Meters/Circle |

13*19*3 | 40Meters/Circle | 51*63*6 | 40Meters/Circle |

13*20*3.5 | 40Meters/Circle | 57*67*5 | 40Meters/Circle |

13*21*4 | 40Meters/Circle | 60*70*5 | 40Meters/Circle |

16*22*3 | 40Meters/Circle | 64*74*5 | 40Meters/Circle |

16*23*3.5 | 40Meters/Circle | 76*86*5 | 40Meters/Circle |

16*25*4.5 | 40Meters/Circle | 76*88*6 | 40Meters/Circle |

19*25*3 | 40Meters/Circle | 85*95*5 | 10Meter/Circle |

19*29*5 | 40Meters/Circle | 85*97*6 | 10Meter/Circle |

20*30*5 | 40Meters/Circle | 89*99*5 | 10Meter/Circle |

22*30*4 | 40Meters/Circle | 89*100*5.5 | 10Meter/Circle |

25*35*5 | 40Meters/Circle | 89*101*6 | 10Meter/Circle |

28*38*5 | 40Meters/Circle | 95*106*5.5 | 10Meter/Circle |

30*38*4 | 40Meters/Circle | 102*112*5 | 10Meter/Circle |

30*39*4.5 | 40Meters/Circle | 102*113*5.5 | 10Meter/Circle |

30*40*5 | 40Meters/Circle | 102*114*6 | 10Meter/Circle |

32*40*4 | 40Meters/Circle | 108*120*6 | 10Meter/Circle |

32*42*5 | 40Meters/Circle | 115*127*6 | 10Meter/Circle |

34*42*4 | 40Meters/Circle | 127*139*6 | 10Meter/Circle |

34*44*5 | 40Meters/Circle | 140*152*6 | 10Meter/Circle |

38*48*5 | 40Meters/Circle | 152*164*6 | 10Meter/Circle |

40*48*4 | 40Meters/Circle | 180*194*7 | 10Meter/Circle |

40*49*4.5 | 40Meters/Circle | 219*231*6 | 10Meter/Circle |

40*50*5 | For more dimension,can be customized (ID6mm-ID600). |

Inflatable shaft airbag liner manufacturers weld retaining rings

(brass materials) also function to conduct heat and regulate the

protection of airflow. The drying room and a large number of hanging

hose racks are saved, the production efficiency is improved, and the

intermittent process is changed to a continuous process, except that a

high-temperature oven is added. It should be determined according to the

relevant regulations according to the relevant regulations. [1] The use

of the editorial inflatable shaft is very versatile. Any machine that

has a winding, unwinding or slitting machine can be used for the

inflation shaft, even the light metal industry. The second is the

irregular broken wire phenomenon in the reinforcing layer inside the

high-pressure hose. When the outer layer of the high-pressure rubber

hose is opened, the reinforcing layer is not rusted. The joint and the

net welding fixture are only irregular broken wires. The main reason is

that the high-pressure hose is subjected to high frequency and constant

impact.

Large plastic coated metal hoses should be supported when

used. The use of thermoplastic rubber or plastic eliminates the need

for a vulcanization process. The outer rubber layer protects the steel

wire from damage, and the steel wire layer is a skeleton material for

reinforcing. Since the pipe is of a metallic nature, some of the waste

should be oxidized in the pipe, and some of the slag will affect the

welding effect. The axial displacement generated by the system needs to

be absorbed by the arrangement of the pipes. The two ends are welded to

the bellows and end rings and metal hose joints and are widely used in

our lives.

Packing

Order Details

Item Name | Air Bladder for Air Expanding Shaft |

MOQ(Minimum Order Quantity) | 5 Meters |

Lead time | 5-7 days after receiving the deposit |

Calculated Weight | Based on different dimension to calculate |

Package | Carton/Wooden Box |

Price Term | EXW,FOB, CIF, etc |

Payment term | TT,L/C,Western Union |

Country of Origin | China |

Hot Tags: air in bladder, China, manufacturers, suppliers, factory, quotation, pricelist, buy