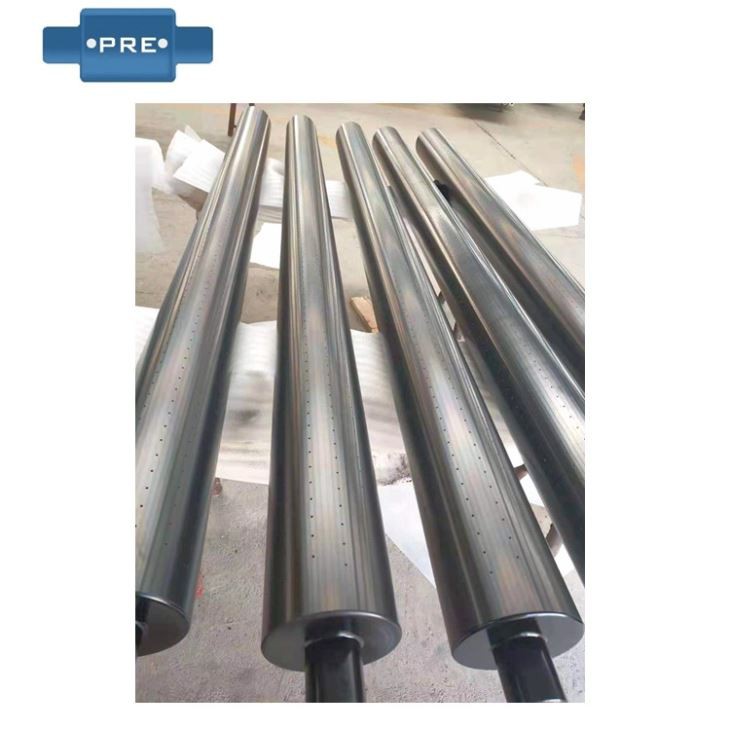

Aluminum Conveyor Steel Idler Roller

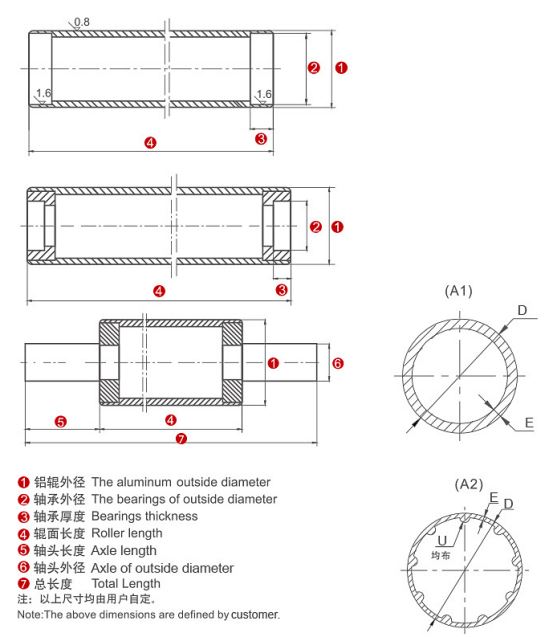

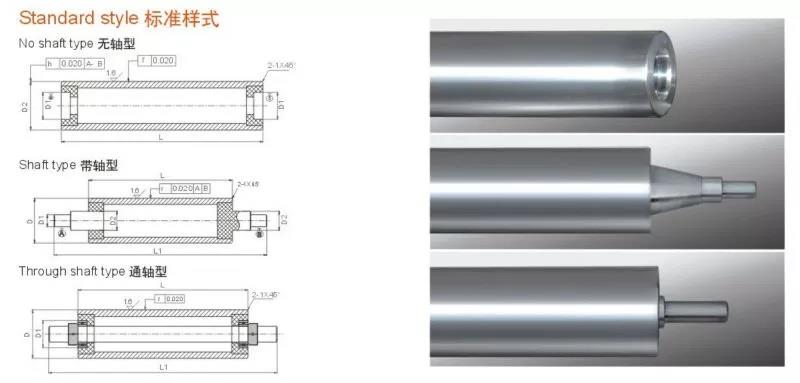

Aluminum tube is also called aluminum roller, it is made of advantaged aluminum alloy material. It has all kinds of modules and sizes. Inside the roller, there is a strong rib structure, chich is very fixed. And the Omni-axes is controlled by dynamic balance correction treatment, which limits to...

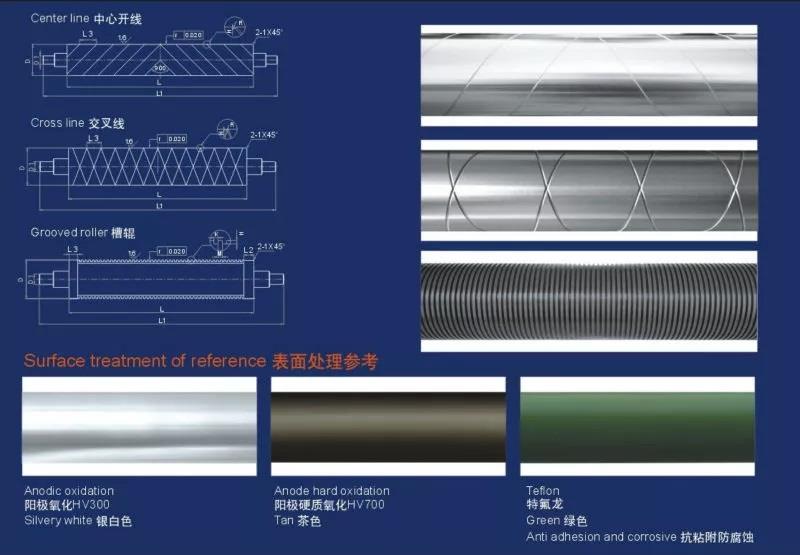

Aluminum tube is also called aluminum roller, it is made of advantaged aluminum alloy material. It has all kinds of modules and sizes. Inside the roller, there is a strong rib structure, chich is very fixed. And the Omni-axes is controlled by dynamic balance correction treatment, which limits to 2g. with the special cutting method, the roll surface's lustrousness is from 1.6 to 0.8, and coaxially is 0.02mm. the axle end under technology processing and with best bearing, though it is running with high speed, it still works well. according to different industry, the roller can also be used in anodic oxidation HV300, HV700, Teflo, it can bear the stuff working surrounding.

Feiya aluminum tube is with High strength, Small resistance, Light

weight, Flexible rotation, and no rusting. It is widely used in

spinning, electric wire and cable, metal-processing industry, paper

industry, rubber industry, plastics industry and mechianical industry.

Specification Table

O.D(mm) | I.D(mm) | Wall Thickness | Stiffener |

Ф32 Ф33 Ф40 | Ф24 Ф27 Ф34 | 4:00 3:00 3.00 |

8 |

Ф40.5 Ф42.5 serrated roller Ф43.8 | Ф31 Ф30 Ф34.5 | 5.00 4.50 5.00 | |

Ф47 Ф50.5 Ф51 with groove | Ф40.8 Ф40.5 Ф38 | 3.00 5.00 6.50 | 8

6 |

Ф55 Ф58.5 Ф61 | Ф46.5 Ф51.5 Ф51 | 4.50 3.50 4.90 | 6 8 6 |

Ф70 serrated roller Ф71 Ф71 | Ф46 Ф63.2 Ф61 | 7.20 4.50 3.50 |

8 7 |

Ф74.5 Ф75.5 Ф80 | Ф60 Ф66 Ф73 | 7.20 4.50 3.50 |

8 8 |

Ф81 Ф81 Ф80 | Ф72.5 Ф71 Ф69 | 4.30 5.00 5.50 | 8 8 8 |

Ф90 Ф99 Ф101 | Ф81 Ф90.5 Ф92 | 4.50 4.30 4.50 | 8 8 7 |

Ф101.5 Ф101 Ф101 | Ф91.5 Ф89 Ф86.3 | 4.50 11.00 11.00 | 7 8 8 |

Ф111 Ф115 Ф116 | Ф102 Ф93 Ф94 | 4.50 11.00 11.00 |

7 8 |

Ф120.5 Ф121.5 Ф130.5 | Ф105.5 Ф111.5 Ф118 | 7.50 5.00 6.25 |

9 |

Ф140 Ф145 Ф151.5 | Ф120 Ф123 Ф139.5 | 10.00 11.00 6.20 | 8 7 8 |

Ф151.5 Ф153 Ф162 | Ф131.5 Ф121 Ф148 | 10.00 11.00 7.00 |

9 |

Ф184 Ф203 | Ф168 Ф179 | 8.00 12.00 | |

Ф150.5 Ф151 Ф200 Ф320 | Ф136.5 Ф140 Ф186 Ф296 | 7.00 5.50 7.00 12.00 |

10 |

Aluminum guide roll surface coating process

1, electrophoretic coating

On the basis of anodizing, the aluminum guide roller is subjected to electrophoretic induction, and a layer of water-soluble acrylic paint film is masked on the oxide film to form an anodized film and an acrylic paint film composite film. The hand feels smooth and delicate, and the outside is not beautiful and bright. In addition to the original oxidized color, it can make more colorful colors such as white and green.

2, black powder coating

Aluminium guide roller has more than 200 kinds of color choices, giving the designer a wide space, the function is shaken, the paint film has strong strength, and it is not easy to peel off, acid resistance, salt spray resistance, mortar resistance, weather resistance and aging resistance. The coating is non-volatile, non-oxidizing, non-polluting and pervasive in the air, and has good environmental protection functions. The appearance of the dirt is washed and the appearance is new.

3, black fluorocarbon spray

After being electrostatically induced, a polyvinylidene fluoride lacquer coating was sprayed on the surface of the aluminum alloy substrate. The fluorocarbon coating is a polyvinylidene fluoride or fluorocarbon coating. Aluminum alloy guide roller manufacturers can have long-term color retention, anti-aging, anti-corrosion, anti-big gas pollution, and its fluorocarbon bond is one of the strongest molecular bonds superior to its molecular structure. Fluorocarbon coating is the wrist of a high-grade exterior coating process. It has the advantages of average color inconsistency, and the ability to resist discoloration and staining.

Products are widely used in: printing machinery, packaging machinery, corrugated machinery, cable equipment, textile machinery, rubber machinery, tire machinery, assembly lines, paper machinery, construction machinery, food machinery, printing machinery, motors, spinning machinery, rubber machinery , tire machinery, electrical machinery, paper machinery, food machinery, plywood machinery, wind development equipment, new energy equipment, conveyor machinery, cutting machinery, glass repair equipment, automation and other industries........

Packing

Order Details

Item Name | Aluminum conveyor steel idler roller |

MOQ(Minimum Order Quantity) | 1PC |

Lead time | 10-15 days after receiving the deposit |

Calculated Weight | Need to count |

Package | Wooden Box/Pallet packing/according to clients’demand |

Price Term | EXW,FOB, CIF, etc |

| Payment term | TT,L/C,Western Union |

| Country of Origin | China |

Hot Tags: aluminum conveyor steel idler roller, China, manufacturers, suppliers, factory, quotation, pricelist, buy