Aluminum Pipe Roller

The guide roller, also known as the leader roller, serves to maintain the product in a normally fixed position during operation. When the copper network is deflected, it will be adjusted back to its original position, and the leading products will always follow the correct path. Aluminum guide...

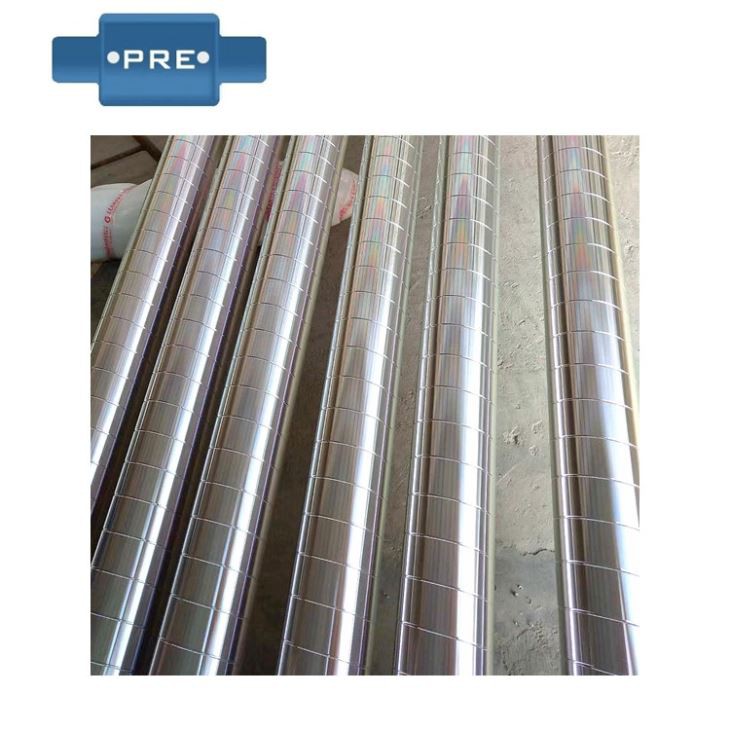

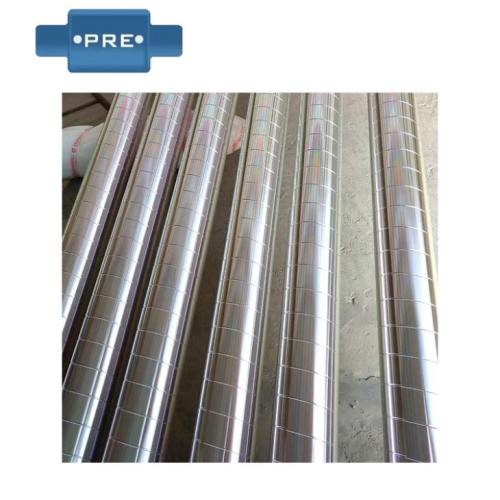

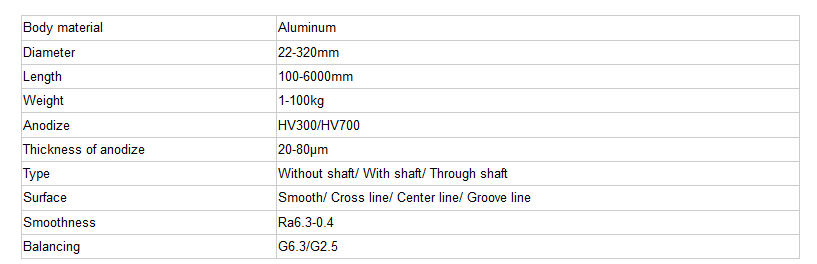

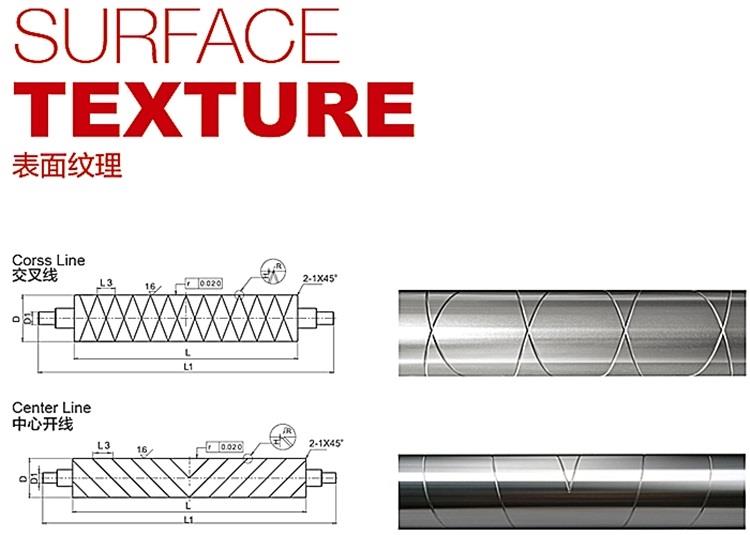

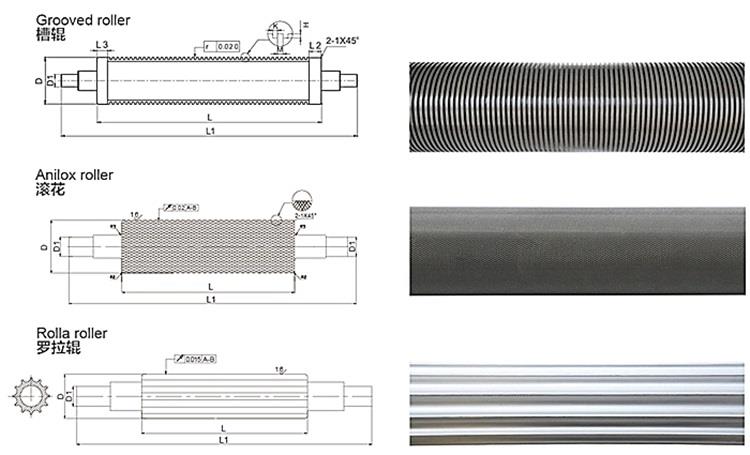

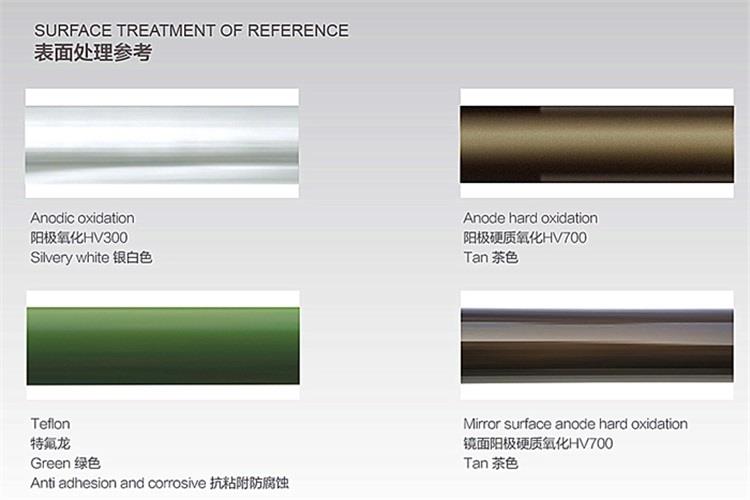

The guide roller, also known as the leader roller, serves to maintain the product in a normally fixed position during operation. When the copper network is deflected, it will be adjusted back to its original position, and the leading products will always follow the correct path. Aluminum guide roller aluminum surface treatment process For aluminum, the color that can be achieved by anodizing is quite limited, usually silver, bronze, titanium, K gold or black. The hard oxidized aluminum guide roller has the advantages of high strength, low resistance, light weight, flexible rotation, no rust on the surface, wear resistance and corrosion resistance. Products are widely used in: packaging machines, bag making machines, printing machines, coating machines, laminating machines, slitting machines, paper machinery, textile machinery and other coil processing equipment.

O.D(mm) | I.D(mm) | Wall Thickness | Stiffener |

Ф32 Ф33 Ф40 | Ф24 Ф27 Ф34 | 4:00 3:00 3.00 |

8 |

Ф40.5 Ф42.5 serrated roller Ф43.8 | Ф31 Ф30 Ф34.5 | 5.00 4.50 5.00 | |

Ф47 Ф50.5 Ф51 with groove | Ф40.8 Ф40.5 Ф38 | 3.00 5.00 6.50 | 8

6 |

Ф55 Ф58.5 Ф61 | Ф46.5 Ф51.5 Ф51 | 4.50 3.50 4.90 | 6 8 6 |

Ф70 serrated roller Ф71 Ф71 | Ф46 Ф63.2 Ф61 | 7.20 4.50 3.50 |

8 7 |

Ф74.5 Ф75.5 Ф80 | Ф60 Ф66 Ф73 | 7.20 4.50 3.50 |

8 8 |

Ф81 Ф81 Ф80 | Ф72.5 Ф71 Ф69 | 4.30 5.00 5.50 | 8 8 8 |

Ф90 Ф99 Ф101 | Ф81 Ф90.5 Ф92 | 4.50 4.30 4.50 | 8 8 7 |

Ф101.5 Ф101 Ф101 | Ф91.5 Ф89 Ф86.3 | 4.50 11.00 11.00 | 7 8 8 |

Ф111 Ф115 Ф116 | Ф102 Ф93 Ф94 | 4.50 11.00 11.00 |

7 8 |

Ф120.5 Ф121.5 Ф130.5 | Ф105.5 Ф111.5 Ф118 | 7.50 5.00 6.25 |

9 |

Ф140 Ф145 Ф151.5 | Ф120 Ф123 Ф139.5 | 10.00 11.00 6.20 | 8 7 8 |

Ф151.5 Ф153 Ф162 | Ф131.5 Ф121 Ф148 | 10.00 11.00 7.00 |

9 |

Ф184 Ф203 | Ф168 Ф179 | 8.00 12.00 | |

Ф150.5 Ф151 Ф200 Ф320 | Ф136.5 Ф140 Ф186 Ф296 | 7.00 5.50 7.00 12.00 |

10 |

Inside the standard use process, it desires to be cleaned and there are many cleansing strategies. what type of technique does the aluminum roller regularly take?

1. guide cleaning method the cleaning agent is implemented to the floor of an aluminum curler, and a copper twine brush is used for cleansing the chrome-plated steel aluminum roller; and the ceramic aluminum curler need to be cleaned with a twine brush. this type of cleansing technique is convenient and does no longer reason pollution, but if it isn't very well cleaned, it's going to have an effect on the ink switch effect. usually suitable for low-wire aluminum rollers or no longer very grimy aluminum rollers.

2. chemical cleaning technique follow the corrosive cleansing agent calmly at the floor of the aluminum curler. if vital, wrap a layer of plastic products on the surface of the aluminum roller to volatilize the liquid. the rate of the aluminum manual roller is ablated for 1 to 48 hours. after the ink is adequately softened, the aluminum curler is washed with water or alcohol in mixture with a manual cleansing method. this form of cleansing method has an excellent cleansing effect, but it has a positive corrosive effect at the aluminum roller, and the suzhou aluminum manual roller will purpose environmental pollutants.

Three. ultrasonic cleansing method: the aluminum curler is immersed in an ultrasonic cleaning tank full of a chemical cleaning answer. whilst cleansing, the aluminum curler rotates slowly, and the frequency conversion tool capable of transmitting high-frequency sound waves within the liquid pool begins to paintings, inflicting the solution to vibrate and generate bubbles. beginning inward, the ink is ejected from the mobile, and the cleaning time is normally 15 to forty five minutes.

Application

Order Details

Item Name | Aluminum roller |

MOQ(Minimum Order Quantity) | 1PC |

Lead time | 10-15 days after receiving the deposit |

Calculated Weight | Need to count |

Package | Wooden Box/Pallet packing/according to clients's requirement and demand |

Price Term | EXW,FOB, CIF, etc |

| Payment term | TT,L/C,Western Union |

| Country of Origin | China |

Hot Tags: aluminum pipe roller, China, manufacturers, suppliers, factory, quotation, pricelist, buy