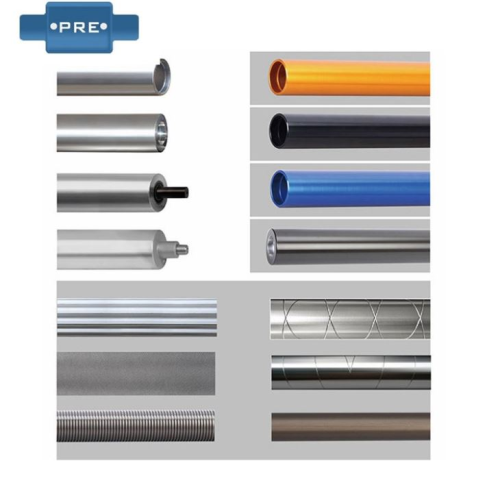

Aluminum Roller Blind Tubes

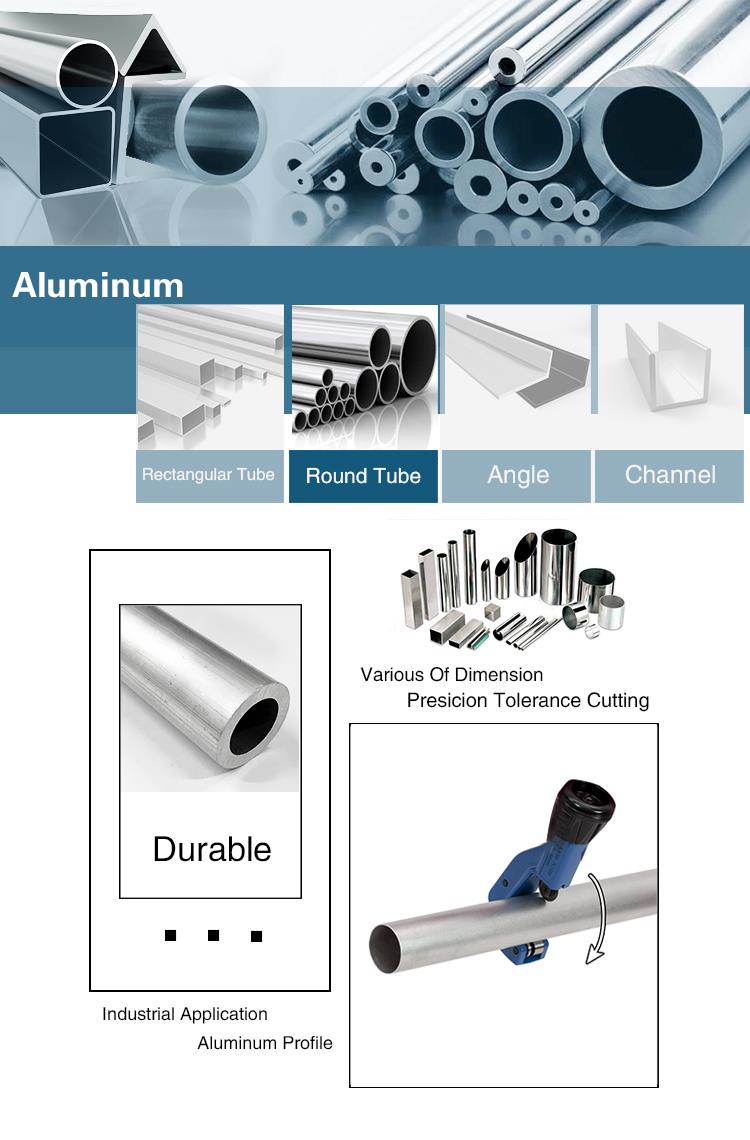

Aluminum tube;aluminum pipe There may be one or more closed through holes, the wall thickness and the cross section are uniform, and are delivered in a straight line or in a roll. Widely used in automobiles, ships, aerospace, aviation, electrical, agricultural, mechanical and electrical, home and other industries.

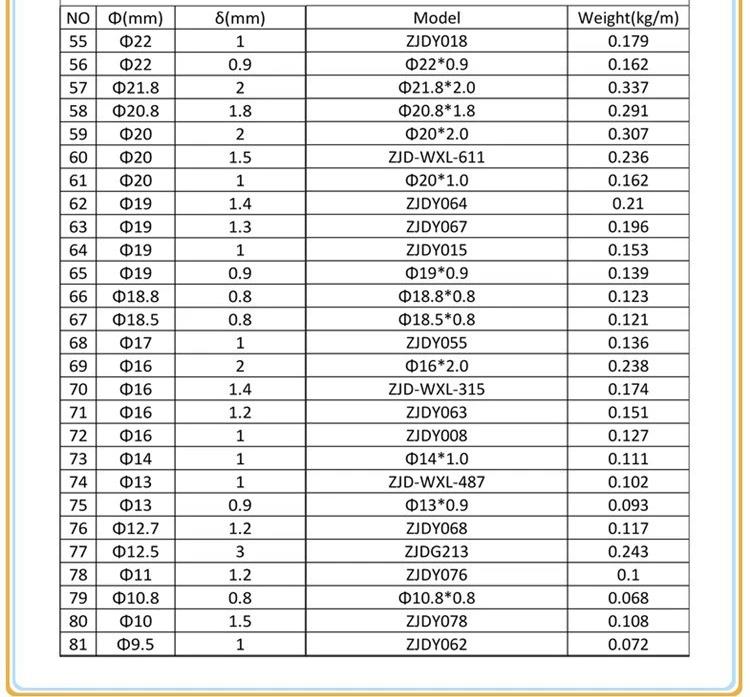

Aluminium Tube Specification | |||

Material | Aluminium Alloy or Non-alloy | ||

Grade | 1000 series: 1050,1060,1070,1080,1100,1435, etc 2000 series: 2011,2014,2017,2024, etc 3000 series: 3002,3003,3104,3204,3030, etc 5000 series: 5005,5025,5040,5056,5083, etc 6000 series: 6101,6003,6061,6063,6020,6201,6262,6082, etc 7000 series: 7003,7005,7050,7075, etc | ||

Standards | ASTM, ASME,EN, JIS, DIN,GB/T etc | ||

Outer Diameter | 6-720mm | ||

Thickness | 0.5-68mm | ||

Length | 3000-6000mm | ||

Aluminum tube;aluminum pipe

There may be one or more closed through holes, the wall thickness and the cross section are uniform, and are delivered in a straight line or in a roll. Widely used in automobiles, ships, aerospace, aviation, electrical, agricultural, mechanical and electrical, home and other industries.

Welding of aluminum tubes 1 Welding characteristics: Aluminum and

aluminum alloys have strong thermal conductivity and large heat

capacity, large coefficient of linear expansion, low melting point and

low temperature strength. The welding is difficult, and certain measures

should be taken to ensure the welding quality. So here is a brief

introduction to the correct aluminum welding method.

1. Welding

characteristics: Aluminum and aluminum alloy have the characteristics of

strong thermal conductivity, large heat capacity, large coefficient of

linear expansion, low melting point and low temperature strength. The

welding is difficult, and certain measures should be taken to ensure the

welding quality.

2. Cleaning of pipe fittings and welding wire,

cleaning the surface of the wire and the 50mm sides of the wire with

acetone, brushing the surface oxide film with stainless steel wire to

expose the metallic luster, cleaning the broken hole must be welded

within 2 hours, cleaning A good wire is placed in an unused cylinder and

must be used within 8 hours, otherwise it will be reprocessed.

3.

The tungsten rod is made of tantalum tungsten rod, the argon gas is not

less than 99.96%, and the water content should not be more than 50mg/m3.

4 The ambient temperature is not lower than 5 °C, otherwise it should

be preheated to 100~200 °C before welding, relative humidity control.

The welding of aluminum tubes can be welded by the following welding methods

1.

Commonly used is argon arc welding. The welding wire is made of 4

series, 5 series, 6 series, which are sold in general hardware stores.

2.

The low temperature M51 and M51-F welding wire are operated under the

working temperature of 179 degrees. The affinity for the welding

materials of 1, 2, 3, 4 and 6 series is better, and it is often used to

control the deformation control. , or welding in the case of

particularly thin.

3, WE53 low temperature aluminum welding rod for

the welding of 7 series of aluminum alloy, the welding working

temperature is 380-400 degrees, the advantage is that it does not need

to assist any flux welding during welding, thus preventing some flux

during the welding process. Residual, and the welding strength is very

high, can solve the welding of 3 series aluminum alloy and casting, or

die casting.

4, Q303 low-temperature aluminum welding wire for the 1,

2, 3, 4, 6 series of aluminum alloy welding also shows some special

advantages in the narrow gap welding is not very good angle.

Order Details

Item Name | Aluminum Roller Tube |

MOQ(Minimum Order Quantity) | 1PC |

Lead time | 10-15 days after receiving the deposit |

Calculated Weight | Need to count |

Package | Wooden Box/Pallet packing/according to clients's requirement and demand |

Price Term | EXW,FOB, CIF, etc |

| Payment term | TT,L/C,Western Union |

| Country of Origin | China |

Hot Tags: aluminum roller blind tubes, China, manufacturers, suppliers, factory, quotation, pricelist, buy