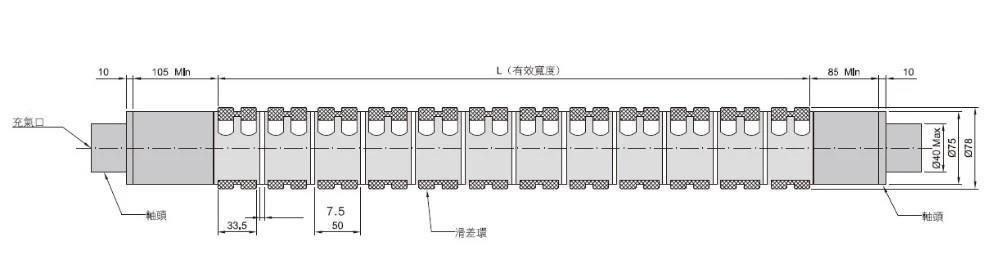

Slip Shaft

The shaft of the slip shaft is basically welded by the shaft and the shaft head. We create a steel forging with a precision forging equipment. The forged core shaft is stable and stable, has a long service life, and is accurate in winding materials and high in running speed. The main spare...

The shaft of the slip shaft is basically welded by the shaft and the shaft head. We create a steel forging with a precision forging equipment. The forged core shaft is stable and stable, has a long service life, and is accurate in winding materials and high in running speed. The main spare parts, the processing procedure is cumbersome and requires high precision. It is mainly used for the main parts of various mechanical equipment such as slitting machine, bag making machine, printing machine, packaging machine, etc., and has a wide range of uses.

How to maintain and maintain it?

1. In the process of using the

slip shaft, the operator needs to use the air gun to clean the slip

shaft to clean dust and debris.

2. When the slip shaft is in use,

because the slip ring and the shaft friction will produce a certain

amount of heat, this is a normal phenomenon, but if the heat is

excessive, this is an abnormal phenomenon, and the excessive heat is

caused by the friction. In this case, it is basically going to the back

of the large diameter material to appear this situation, because the

larger the winding diameter, the greater the tension required, if the

air pressure is not large enough, that is, the tension is not large

enough, The slip ring is excessively slippery and hot. In the early

stage, a lot of dust will appear due to excessive wear of the wool felt.

When the wool felt is worn, the airbag is directly worn and the

slippery shaft leaks. Therefore, if the fever is excessive, it is

necessary to find early treatment and adjust the tension of the machine

to prevent more serious situations.

3. In the process of loading

and unloading, firstly, in the case of inflation, all the raised keys

are in a sinking state, and then the materials are assembled or

unloaded; many manufacturers are because there are some slip rings that

are not stuck. Still in a raised state, or vigorously shirking large

rolls of material, over time, this action will lead to inflexibility of

the partial slip ring, and finally the entire slip unit is scrapped.

4.

In the early days, many slitting machines were not equipped with

receiving racks. If the winding material was too heavy, and at the

moment of unloading, it was completely in a single-sided cantilever

state. Under the action of material gravity, the whole slip axis would

be slow. Slow deformation, axial bending, and more serious direct axial

fracture. Therefore, if your material is too heavy and there is no

receiving rack, it is recommended that you take the time to install a

receiving rack. While protecting the shaft, it also reduces the workload

of the staff and greatly improves the safety.

5. After using the

slip shaft for a period of time, it is necessary to loosen the ferrule

of the tail of the slip shaft, move it 20mm or more, and then move the

slip ring in sequence, and also use the air gun to clean dust and

debris. Etc., many manufacturers use the slip shaft from the beginning

to the end without regular cleaning and maintenance, and finally lead to

excessive dust and debris, under the action of the slip ring friction,

the shaft slip ring is worn, resulting in a whole slip The difference

axis is scrapped or seriously damaged.

Order Details

Item Name | slip shaft |

MOQ(Minimum Order Quantity) | 1Pc |

Lead time | 15-18 days after receiving the deposit |

Calculated Weight | Depend on dimension |

Package | Wooden Box |

Price Term | EXW,FOB, CIF, etc |

Payment term | TT,L/C,Western Union |

Country of Origin | China |

Hot Tags: slip shaft, China, manufacturers, suppliers, factory, quotation, pricelist, buy