Guiding Controller

PRE has the industry's leading drive technology and coil control solutions. From sensors to guiding controllers, from small to large industrial clutches and brakes, we have the industry's broadest product specifications and the most advanced manufacturing and application technologies. We...

PRE has the industry's leading drive technology and coil control solutions. From sensors to guiding controllers, from small to large industrial clutches and brakes, we have the industry's broadest product specifications and the most advanced manufacturing and application technologies. We adhere to the innovation of products and technologies and constantly exceed the expectations of users.

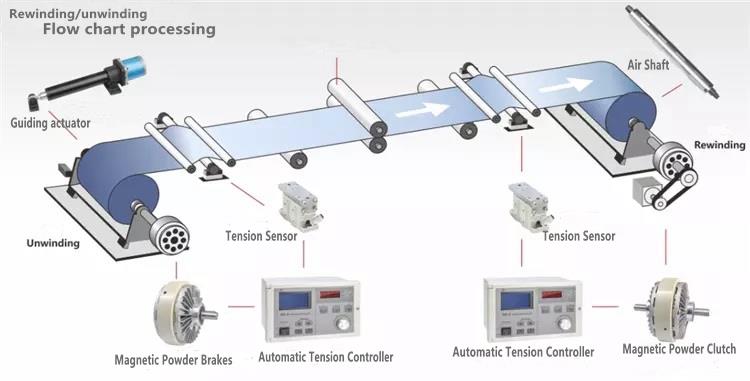

The coil material in the web control device business refers to sheet products such as paper, film, foil, fiber, rubber, and woven fabric. In order to eliminate the positional deviation of the coil during processing, ensure that the coil is accurately run at the specified position to achieve the required precision during operation and the winding is neat, we will make you according to the difference of the coil and the actual application. Brought a variety of correction application solutions.

1. Precautions during installation

a.Pay great attention to avoid installation deviations during installation

(1) The upper pressing gland should be carried out after the coupling is aligned. The bolts should be evenly supported to prevent the end face of the gland from being skewed. Check the points with a feeler gauge. The error is not more than 0.05 mm.

(2) Check the fit clearance (ie, concentricity) between the gland and the outer diameter of the shaft or bushing. The circumference should be uniform. Check the tolerance of each point with a feeler gauge to be no more than 0.01 mm.

b. The amount of spring compression should be carried out according to the regulations. It is not allowed to be too large or too small, and the required error is 2.00 mm. Over the assembly, the end face is pressed and the other end face is worn. Too small will cause insufficient specific pressure and will not seal.

c. After the moving ring is installed, it can be flexibly moved on the shaft. After the moving ring is pressed against the spring, it should be able to spring back automatically.

2. Precautions when disassembling

a. Care should be taken when disassembling the mechanical seal. Do not use the hand hammer and the flat shovel to avoid damage to the sealing components. A pair of wire hooks can be made, and the sealing device is pulled out in the direction of self-supporting profit and loss into the gap of the transmission seat. If the scale is not removed, it should be cleaned before disassembly.

b. If mechanical seals are used on both ends of the pump, take care of each other during assembly and disassembly to prevent loss.

c. For the mechanical seal that has been operated, if the gland is loose to move the seal, the static and dynamic ring parts must be replaced and should not be re-tightened for continued use. Because after the turbulence, the original trajectory of the friction pair will change, and the sealing of the contact surface will be easily damaged.

Delivery:

Packing:

Order Details

Item Name | PG-300A Offset Pivot Guide |

MOQ(Minimum Order Quantity) | 1pc |

Lead time | 10-15 days after receiving the deposit |

Calculated Packing Size | 50cm*45cm*36cm |

Package | Wooden Box |

Price Term | EXW,FOB, CIF, etc |

Payment term | TT, L/C,Western Union |

Country of Origin | China |

Hot Tags: guiding controller, China, manufacturers, suppliers, factory, quotation, pricelist, buy