Cable Tension Measurement

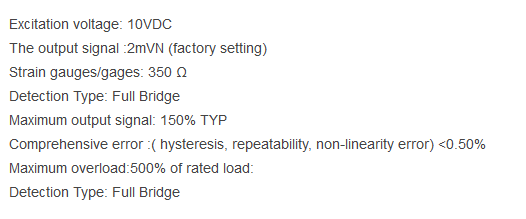

Tension sensors are very common in the industry, and tension sensors can be classified into different degrees of accuracy or grades depending on their overall performance. Specific accuracy levels govern the combination of certain parameters such as nonlinearity, hysteresis, temperature effects,...

Tension sensors are very common in the industry, and tension sensors can be classified into different degrees of accuracy or grades depending on their overall performance. Specific accuracy levels govern the combination of certain parameters such as nonlinearity, hysteresis, temperature effects, creep, and the like. In theory, certain system accuracy parameters are highly horizontally dependent on use, load introduction, and interference, such as overvoltage and surge maintenance.

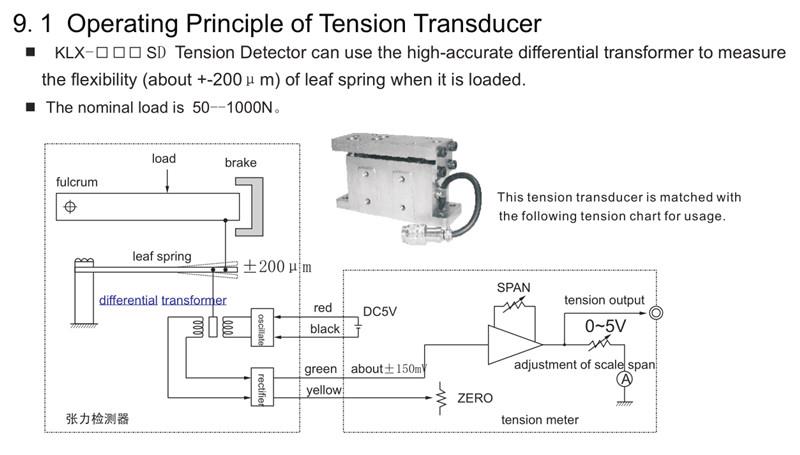

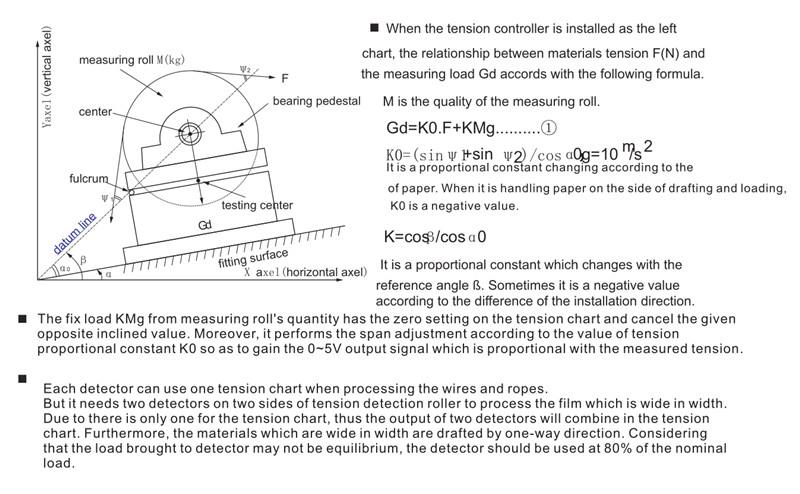

LC Series Through-Hole Tension Detector

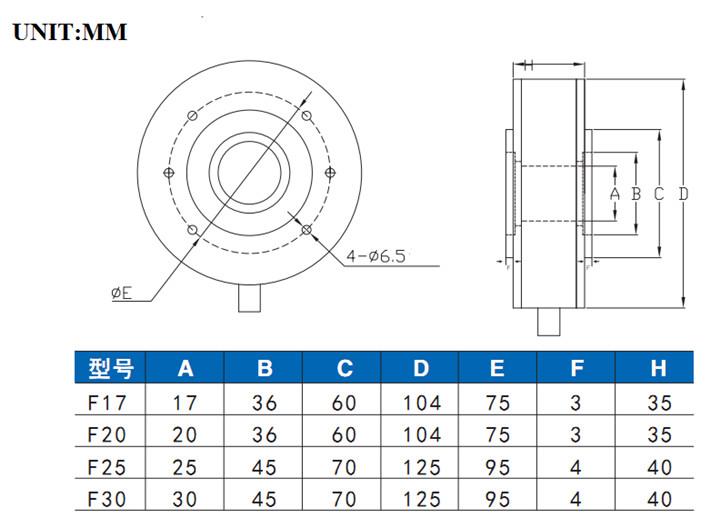

Installation:

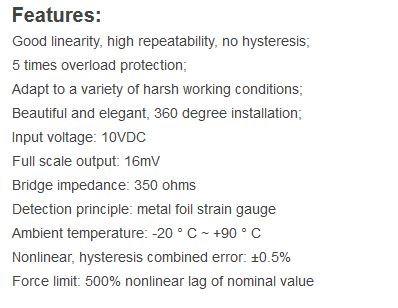

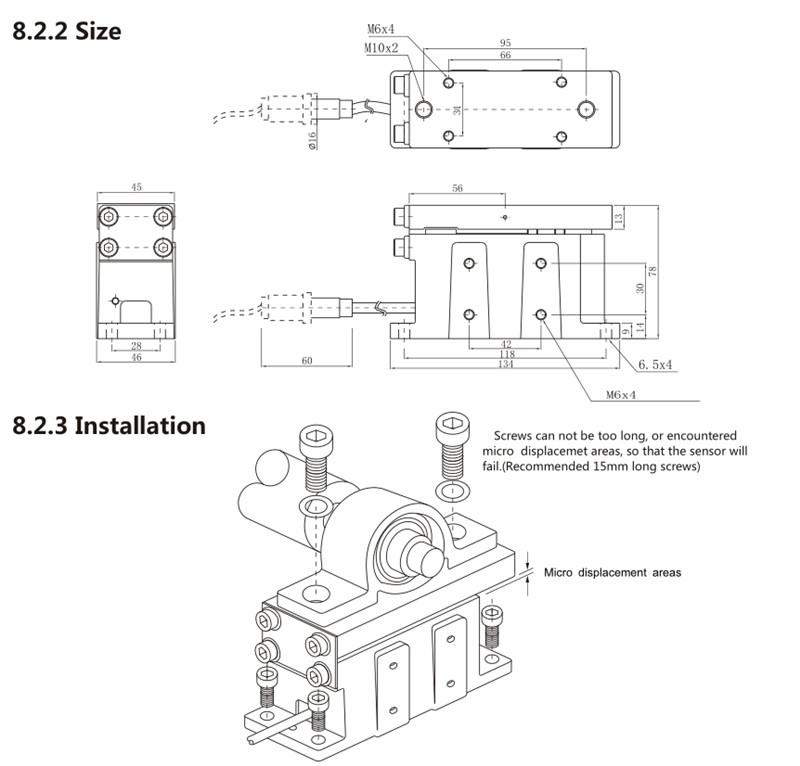

Foot Mounted Tension Sensor

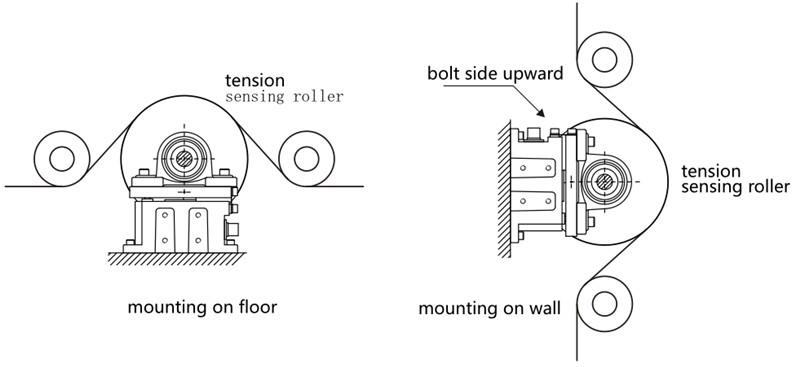

Mounting of Tension Sensors:

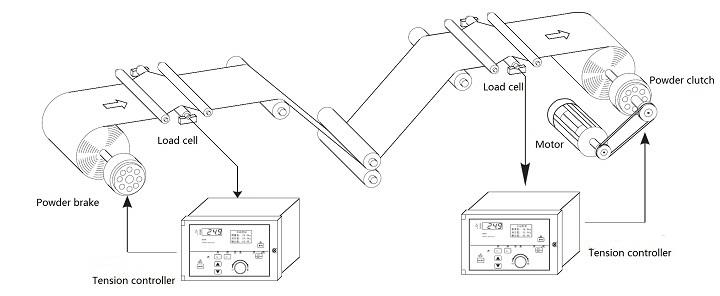

Tension sensor connection method

Tension sensors are very common in the industry, and tension sensors can be classified into different degrees of accuracy or grades depending on their overall performance. Specific accuracy levels govern the combination of certain parameters such as nonlinearity, hysteresis, temperature effects, creep, and the like. In theory, certain system accuracy parameters are highly horizontally dependent on use, load introduction, and interference, such as overvoltage and surge maintenance. So, what are the terms about the accuracy of the tension sensor?

Accuracy level

The level of a tension sensor is subject to the accuracy level of the tension sensor. The tension sensor is classified by the letter grade and the maximum number of divisions of the tension sensor (in 1000 units).

2. Calibration index value of tension sensor (ν)

For the purpose of precision grading, the index value of the tension sensor expressed in mass units used in the tension sensor experiment.

3. Calibration index of tension sensor (n)

For the purpose of precision grading, the number of verification scales of the tension sensor used in the tension sensor experiment.

4. Nonlinear

The tension sensor calibration curve is related to the deviation of one of the following lines:

1) This straight line passes the 75% of the measurement range (oiml tension sensor verification) and the tension sensor output of the minimum load.

2) A line connecting the zero load to the rated load output value.

3) The best straight line suitable for the output value after the minimum interpolation method, the straight line passes the zero point load. Everything is stopped at 20 °C.

Lag

The difference between the reading taken from the minimum load and the reading taken from the maximum load, under the same load applied.

6. Creep (creep)

The output of the weighing result changes over time with a stable load (greater than 90% of the load cell weighing), all environmental conditions and other variables.

Oiml r76 begged for a 30-minute experiment and rules the error limits for this period and the last 10 minutes (20th - 30th minute). Ntep begged to abort the 1 hour experiment and rule the error extremes for this period.

7. Minimum static load output recovery value (mdlor)

The applied load is at least 90% of the load cell's rated capacity (only for oiml), and the minimum static load output measured before and after 30 minutes of measurement is discontinued.

8. Effect of temperature on minimum static load output

The change in the minimum static load output caused by the change in temperature around the tension sensor.

9. The effect of temperature on flexibility

The change in flexibility caused by changes in the temperature around the tension sensor.

10. Comprehensive error

The straight line of the output and rated load output when no load is connected and the maximum tendency of the characteristic curve when increasing the load and reducing the load.

Application

Order Details

Item Name | LC Through-Hole Tension Detector |

MOQ(Minimum Order Quantity) | 1Pc |

Lead time | 5-7 days after receiving the deposit |

Calculated Packing Size | 20cm*10cm*10cm, 4kg/Pc |

Package | Carton |

Price Term | EXW,FOB, CIF, etc |

Payment term | TT,L/C,Western Union |

Country of Origin | China |

Order Details

Item Name | LX Foot-Mounted Tension Detector |

MOQ(Minimum Order Quantity) | 1Pair(2pcs) |

Lead time | 2 days after receiving the deposit |

Calculated Packing Size | 20cm*15cm*15cm,4kg/Pair/2pcs |

Package | Carton |

Price Term | EXW,FOB, CIF, etc |

Payment term | TT,L/C,Western Union |

Country of Origin | China |

Hot Tags: cable tension measurement, China, manufacturers, suppliers, factory, quotation, pricelist, buy