Embossing Roller

Application Embossing roller is applicable to the pattern and surface treatment of all kinds of plastic , leather products (PVC、PU、PP、PC、PS、PET、PE、ABS, etc.) , toilet paper or wallpaper. 1. Paper industry: art paper, wallpaper, paper towels, cigarettes, beer aluminum foil, various wrapping...

Material | SCM440 (42CrMo4) , SUJ2 (100Cr6) , SNCM439(40NiCrMo6) , seamless steel, hardness steel | ||

Structure | Customized according to drawing , all kinds of passageways | ||

Plating | chrome plating | ||

Processing | Customized according to sample pattern | ||

Precision | Surface roughness ≤ Ra0.01µm,(smooth finish:level 14), cooling or heating temperature difference <±1 ℃ , temperature distortion ≤0.01mm , flatness ≤0.005mm, pulsation ≤0.005mm | ||

Application | Embossing roller is applicable to the pattern and surface treatment of all kinds of plastic or leather products (PVC、PU、PP、PC、PS、PET、PE、ABS, etc.). | ||

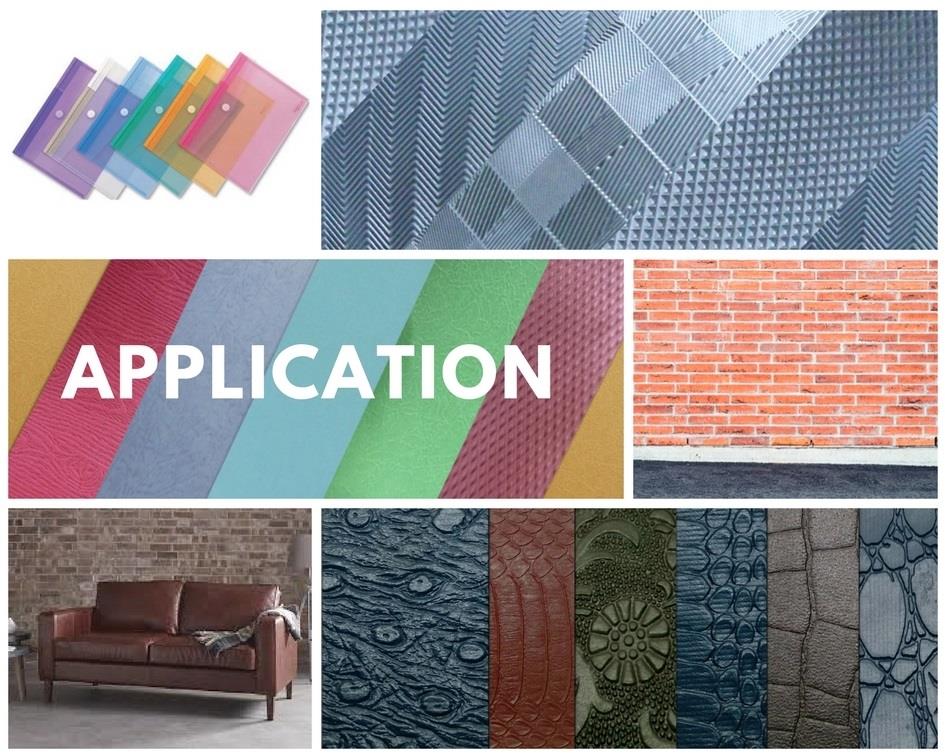

Application

Embossing roller is applicable to the pattern and surface treatment of all kinds of plastic , leather products (PVC、PU、PP、PC、PS、PET、PE、ABS, etc.) , toilet paper or wallpaper.

1. Paper industry: art paper, wallpaper, paper towels, cigarettes, beer aluminum foil, various wrapping paper, special paper.

2, plastic industry: artificial leather, PU leather, all kinds of plastic (film, sheet, sheet), plastic carpet, car interior carpet, placemat, hot stamping tablecloth, advertising light box cloth, Oxford cloth composite and various conveyor belts, etc. .

3. Rubber industry: rubber carpet, sole pattern and various industrial transmissions.

4. Non-woven fabric industry: various flower-shaped hot rolled non-woven fabrics

5, the textile industry: embossing, lining sizing, interlining composite on various textile materials

6. Construction hardware industry: architectural decorative board, non-slip aluminum board, flower glass, wood-plastic board, door cover and embossing on stainless steel decorative pattern board.

The production process of embossing rolls

1. The material of the roller body is generally made of high-quality seamless steel pipe (special material can be customized according to user's needs). After boring the inner hole, the thickness of the pipe wall is uniform and then welded, destressed, car, milled and finished.

2, correct static balance and dynamic balance processing; finished roller coaxiality ≤ 0.02mm;

3, according to the pattern, using different processing techniques, to achieve a clear line of the product, the pattern is exquisite, the layer is rich, the size is accurate.

4, the final surface is plated with hard chrome or other treatment, the hardness can reach HRC58-62.

Third, custom instructions

Please provide the size (diameter, length) of the custom roller and other special requirements, and fax the design drawings to us. If you do not have a design drawing, please contact us and we will provide you with a professional solution. Roll surface pattern, you are best to provide samples, sincerely look forward to working with you!

Embossing roller product description

The embossing roller is suitable for pressing the embossing pattern of plastic sheet, film, aluminum foil, leather, hard board, wallpaper, floor tile, glass, paper, etc., to improve the surface aesthetics, strengthen anti-counterfeiting, protect trademarks and other effects. According to customer requirements, we can develop embossing rolls of different patterns.

Embossing roller production precautions / embossing roller

1. Cutting: seamless steel pipe for roller body, 45 round steel for shaft, Q235 steel plate for end plate, 8mm machining allowance according to drawing size.

2. Turning processing: Turning the joint surface of the joint part of the roller body, end plate and shaft, etc., and processing according to H9/f9 with precision.

3. Weld the combination of the ribs and the shafts at both ends of the roller. Pay attention to correct the coaxiality between the shafts at both ends and the inner sleeve, and only weld the inner end plates on the shaft.

4. Fit the inner part of the combined weld into the roll body and combine the joint end of the welded inner end plate with the roll body.

5. Install the outer end plate on the shafts at both ends, and weld the outer end plate to the junction of the joint surface of the shaft and the roller body.

6. Anneal the roll blanks of the welded combination to eliminate internal stresses.

7. One end of the steel roller shaft is flat, and the standard center hole is drilled.

8. Turning processing: Dividing the parts of the coarse and fine steel roller body to the required dimensions of the drawings. The working surface roughness of the roller body should be no more than 1.6μm; the radial running tolerance of the roller working surface facing the shaft supporting surface (rolling bearing mounting part) is 0.025mm; the roundness of the roller working surface is 0.036mm; the bearing fit The circle is machined to k6 precision. Then the center frame, the end of the car, drilled to size.

9. Process the pattern according to the pattern of the pattern steel roller. The hard chrome layer, the thickness of 0. 03~0. 05mm.

10 Correct the static balance of the steel roll.

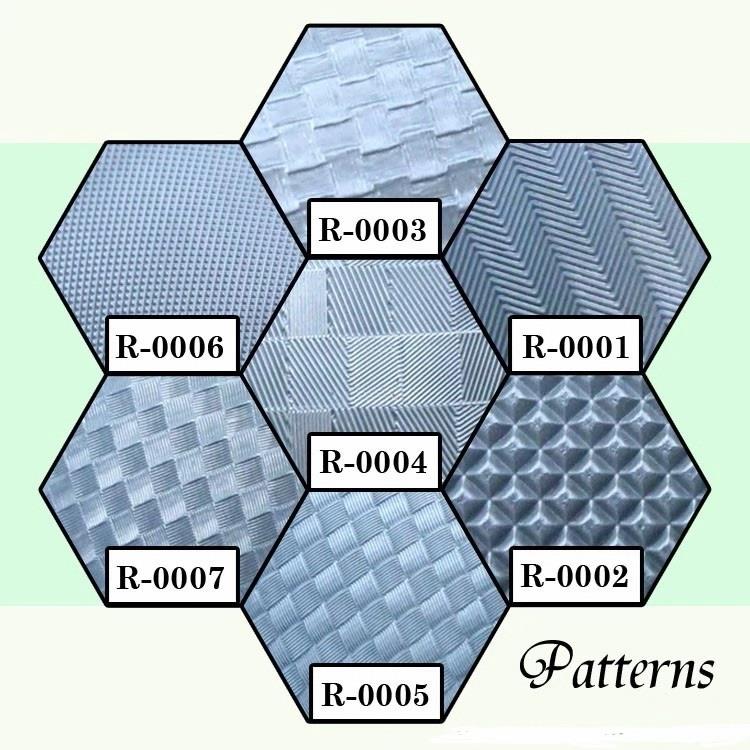

Customized pattern

All pattern possible according to requirement; no size limitation.

Custom embossing rolls and embossing machines for leather,paper, foils, tissue, non-woven and film markets.

We can provide these kinds of pattern for plastic films

1.Linen pattern embossing roller

2.Plastic film embossing roller

3.Hard chrome plated matte roller

4.Mirror tri-helical anilox roller

5.Plastic folder embossing roller

6.Embossing roller

The sample pattern for reference

If you want to order the following style, you can tell us the following number at the inquiry.

MANUFACTURE PROCESS

1.Understand the draft you offer

2.Manufacture our product

3.Polishing

4.Burnishing

5.Sand blasting

6.Burnishing

7.Electroplating

8.Strict quality control and packaging

9.Shipping your product safely

Order Details

Item Name | Embossing roller |

MOQ(Minimum Order Quantity) | 1PC |

Lead time | 15-18 days after receiving the deposit |

Calculated Weight | Need to calculate |

Package | Carton/Wooden Box |

Price Term | EXW, FOB, CIF, etc |

Payment term | TT,L/C,Western Union |

Country of Origin | China |

Hot Tags: embossing roller, China, manufacturers, suppliers, factory, quotation, pricelist, buy