Fife Edge Guides

The world's first correcting device, model 400/830/1898/MC01, was invented by Meiss's FIFE, and the correction controller is the heart of the electronic correction system. The correcting device is a mechanical device for correcting the side error of the coil in the forward movement. The...

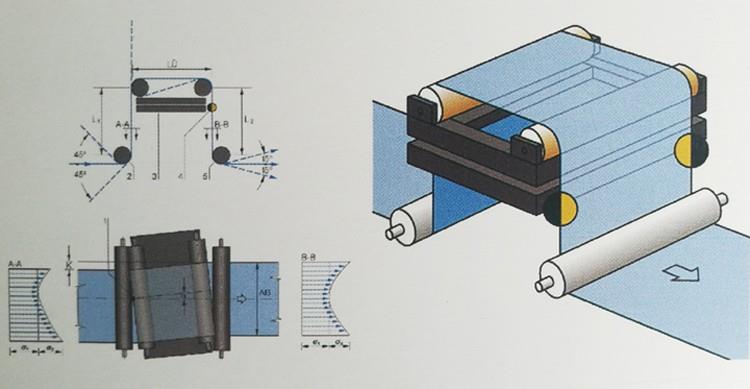

The world's first correcting device, model 400/830/1898/MC01, was invented by Meiss's FIFE, and the correction controller is the heart of the electronic correction system. The correcting device is a mechanical device for correcting the side error of the coil in the forward movement. The displacement correcting is to realize the side correction of the coil by changing the span of the coil at the inlet and the outlet. This correction is made up of a fixed base and one or more rotating devices that act as swinging arms that move around a fixed or virtual point of rotation.

The maximum angle of rotation is ±7.5°. The ideal position of the point of rotation is in the range of the inlet or in the range of no more than 10% during the correction. The Correction Controller provides the corrective control you need to help your production line run efficiently and efficiently. Combined with appropriate sensors, drivers, and other correcting components, the correcting device can provide high-precision, balanced, closed-loop, high-dynamic response servo system.

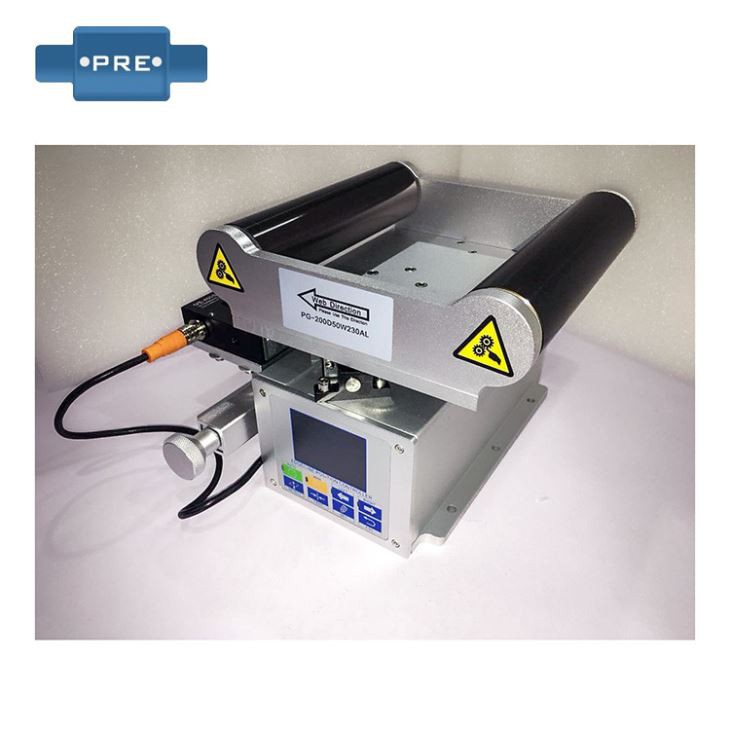

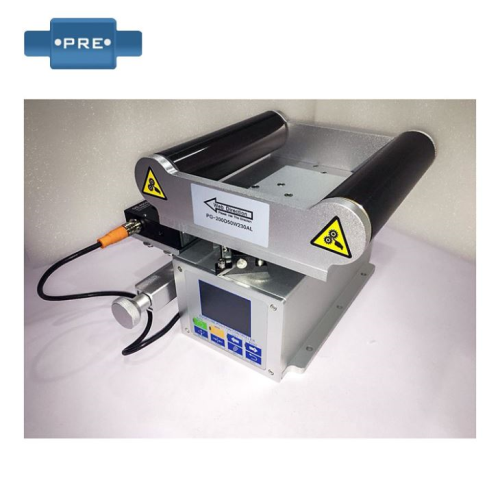

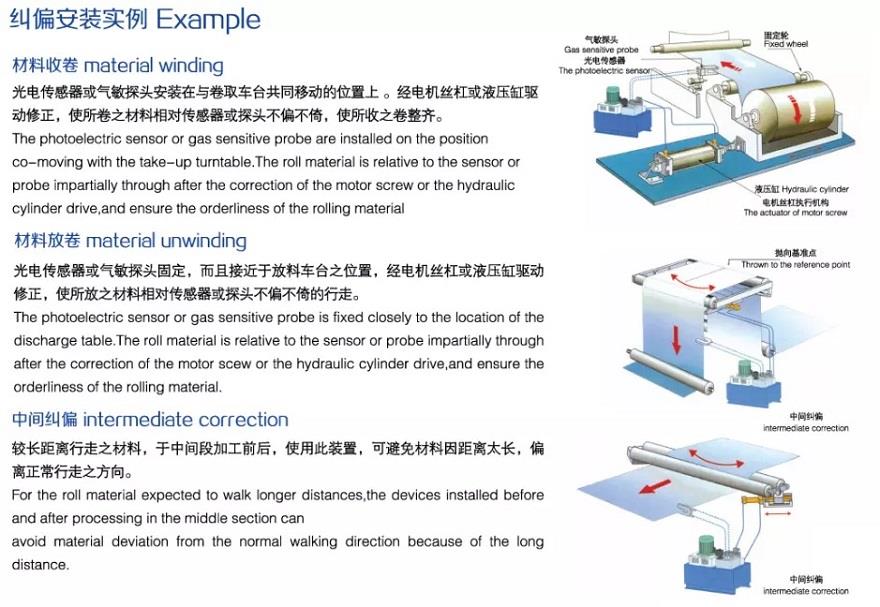

The automated photoelectric correction controller is an automated manipulate machine for controlling the positional deviation of materials which includes coils and cardboard in the course of the transmission procedure. the products have capabilities of automatic detection, computerized tracking, and automated correction. it can song and correct the marking traces or edges of cardboard, film, aluminum foil, strip and other materials to make certain the winding and slitting are neat. the machine can be utilized in mild enterprise, packaging, printing and dyeing, printing, metal rolling and different industries.

The automatic photoelectric correcting actuator makes use of a photoelectric element as a detecting element, first converts the measured change right into a exchange of the signal, and then further converts the optical signal into an electrical sign by the photoelectric element. photoelectric detection method has the benefits of excessive precision, speedy response, non-contact, etc., and many parameters may be measured. the shape of the sensor is simple. customers can pick out numerous specifications in step with their desires, and reap huge application in numerous light business automata.

Fundamental feature of photoelectric correcting device for automatic photoelectric correction controller

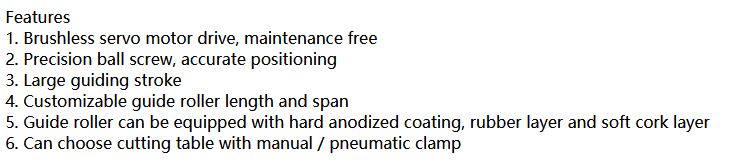

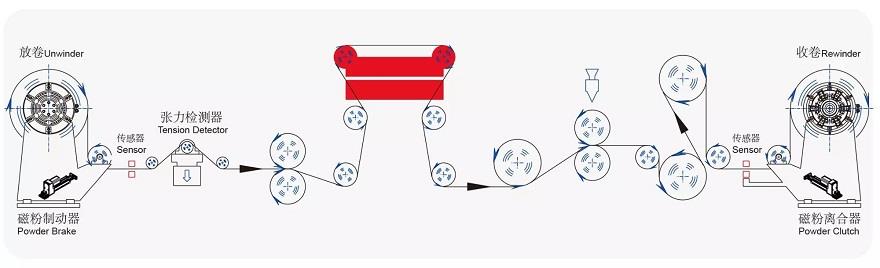

1: electromechanical power or hydraulic cylinder may be used because the driving strength.

2: speedy and correctly role the coil, using a roll width of up to 1930 mm (seventy six.0").

3: layout of low friction ball bushings and rotating rods.

4: the long lasting structure of the correcting actuator can be used constantly for a long time, which substantially reduces the need for protection.

Five: non-obligatory servo plummet to increase settings and internet linear velocity.

6: all popular fife® sensors and controllers can be utilized in heel, centering and observe-up corrections.

7: there are numerous exclusive structures and rollers as a way to pick out from.

8: non-obligatory mounting bracket and stand.

Application

Order Details

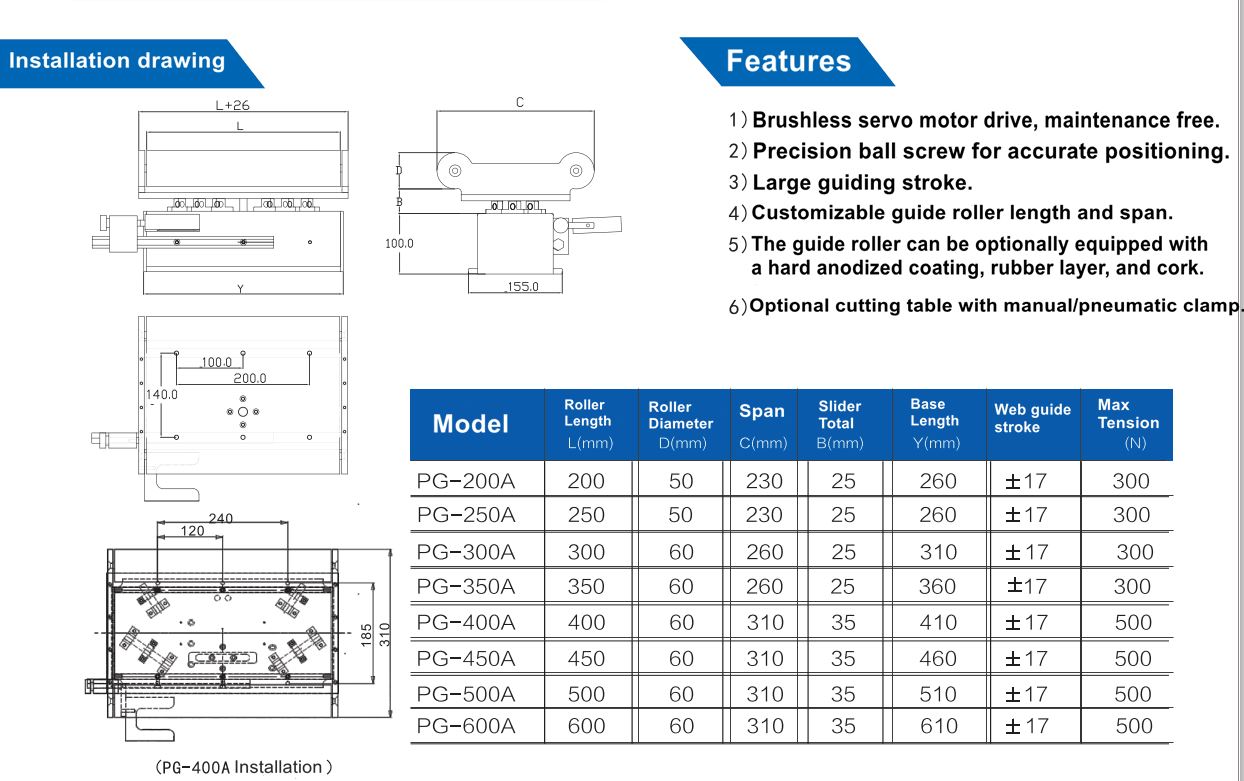

Item Name | Offset Pivot Guide System |

MOQ(Minimum Order Quantity) | 1pc |

Lead time | 10-15 days after receiving the deposit |

Calculated Packing Size | According to model |

Package | Wooden Box |

Price Term | EXW,FOB, CIF, etc |

Payment term | TT, L/C,Western Union |

Country of Origin | China |

Hot Tags: fife edge guides, China, manufacturers, suppliers, factory, quotation, pricelist, buy