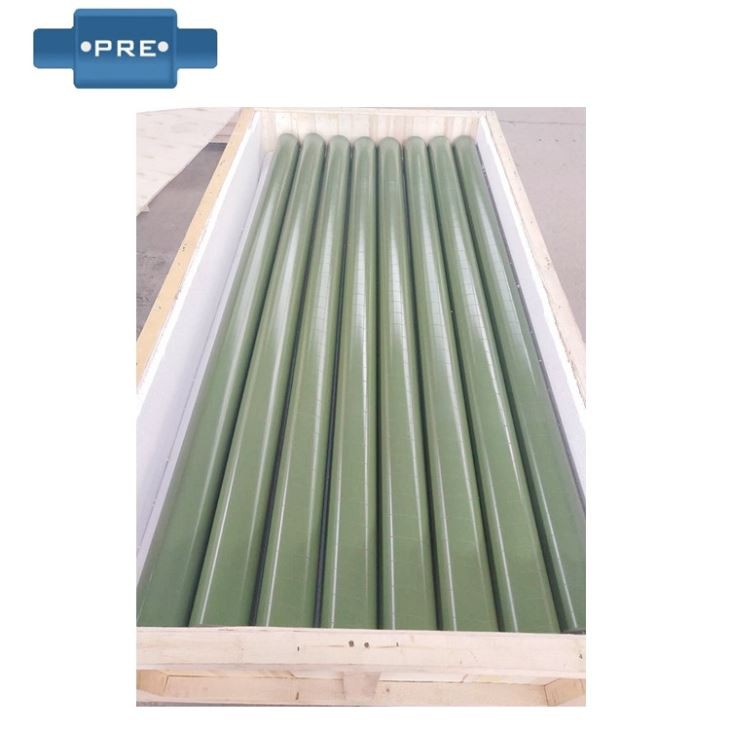

Lightweight Aluminum Idler Roller

Aluminum guide roller and processing technique thereof Since the overall strength of the aluminum guide roller is mainly ensured by the wall thickness of the aluminum block, the aluminum guide tube of the same strength has a thinner wall thickness, so the quality is lighter and the material is...

Aluminum guide roller and processing technique thereof

Since the overall strength of the aluminum guide roller is mainly ensured by the wall thickness of the aluminum block, the aluminum guide tube of the same strength has a thinner wall thickness, so the quality is lighter and the material is saved.

The aluminum guide roller and the processing technology thereof comprise a hollow aluminum tube base, wherein: the aluminum tube base body is provided with a groove at both ends, and the groove is provided with aluminum corresponding to the size of the groove Block, the aluminum block is fixed in the groove, and the aluminum block is provided with a through hole coaxial with the aluminum tube base. The aluminum tube base body with different inner diameters can be selected according to the different strength requirements. Since the overall strength of the aluminum guide roller is mainly ensured by the wall thickness of the aluminum block, the aluminum guide tube of the same strength has a thinner wall thickness. Some, so the quality is lighter and saves material.

Heating aluminum guide roller

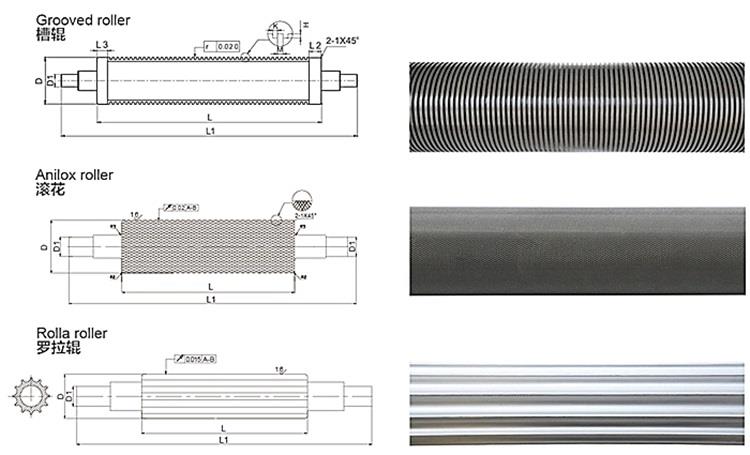

The aluminum alloy guide roller is referred to as aluminum guide roller, medium roller, etc. The technology originated from Japan and developed in Taiwan. It is a new type of accessory that has been developed in recent years in China. It is widely used in printing, papermaking, packaging and other industries. It is an aluminum alloy factory-mechanical processing plant---surface treatment (oxidation) factory, aluminum guide roller three enterprises jointly completed a kind of accessories, the process is more complicated, the communication between enterprises is more troublesome, the period of mechanical processing manufacturers rely on the original The aluminum plant and the oxidation process have solved this process scientifically. The three companies have combined to produce high quality and reasonable price products and serve customers in a timely manner. It is the only one in China that produces raw materials from blank tubes to deep processing. As well as the surface treatment manufacturers, it has played a positive role in the production and promotion of aluminum guide rolls.

O.D(mm) | I.D(mm) | Wall Thickness | Stiffener |

Ф32 Ф33 Ф40 | Ф24 Ф27 Ф34 | 4:00 3:00 3.00 |

8 |

Ф40.5 Ф42.5 serrated roller Ф43.8 | Ф31 Ф30 Ф34.5 | 5.00 4.50 5.00 | |

Ф47 Ф50.5 Ф51 with groove | Ф40.8 Ф40.5 Ф38 | 3.00 5.00 6.50 | 8

6 |

Ф55 Ф58.5 Ф61 | Ф46.5 Ф51.5 Ф51 | 4.50 3.50 4.90 | 6 8 6 |

Ф70 serrated roller Ф71 Ф71 | Ф46 Ф63.2 Ф61 | 7.20 4.50 3.50 |

8 7 |

Ф74.5 Ф75.5 Ф80 | Ф60 Ф66 Ф73 | 7.20 4.50 3.50 |

8 8 |

Ф81 Ф81 Ф80 | Ф72.5 Ф71 Ф69 | 4.30 5.00 5.50 | 8 8 8 |

Ф90 Ф99 Ф101 | Ф81 Ф90.5 Ф92 | 4.50 4.30 4.50 | 8 8 7 |

Ф101.5 Ф101 Ф101 | Ф91.5 Ф89 Ф86.3 | 4.50 11.00 11.00 | 7 8 8 |

Ф111 Ф115 Ф116 | Ф102 Ф93 Ф94 | 4.50 11.00 11.00 |

7 8 |

Ф120.5 Ф121.5 Ф130.5 | Ф105.5 Ф111.5 Ф118 | 7.50 5.00 6.25 |

9 |

Ф140 Ф145 Ф151.5 | Ф120 Ф123 Ф139.5 | 10.00 11.00 6.20 | 8 7 8 |

Ф151.5 Ф153 Ф162 | Ф131.5 Ф121 Ф148 | 10.00 11.00 7.00 |

9 |

Ф184 Ф203 | Ф168 Ф179 | 8.00 12.00 | |

Ф150.5 Ф151 Ф200 Ф320 | Ф136.5 Ф140 Ф186 Ф296 | 7.00 5.50 7.00 12.00 |

10 |

Aluminum guide roller

Deglazing maintenance of aluminum guide rolls: remove the glass layer on the surface of the rubber roller to maintain good surface roughness

De-calcium maintenance of aluminum guide rolls: In the printing process, the rubber roller is often hydrophilic, and the ink-retaining performance is degraded, which causes the ink on the ink roller and the water roller to be inked. The problem is easy to occur when printing the ground and the net. This is often caused by the calcification of the rubber roller. Calcium comes from paper and water during printing. It is constantly depositing calcium on the ink roller and water roller every day. Therefore, calcium removal is an indispensable part in printing. Maintenance procedures.

Cleaning and maintenance of aluminum guide roller color change: When printing dark color to light color and spot color printing color change, it often causes difficulty in cleaning, and the color conversion time is long, thereby reducing the efficiency of the printing machine and causing an increase in the reject rate; Incomplete cleaning will accumulate on the rubber surface and reduce the surface roughness of the rubber roller. Therefore, we emphasize that maintenance should be done from day to day, and every cleaning must be clean and thoroughly clean.

The idle maintenance of the aluminum guide roller: in order to prevent the influence of the temperature on the rubber roller, the good condition of the rubber of the idler seat is maintained, and the ink roller of the empty car needs special care and maintenance.

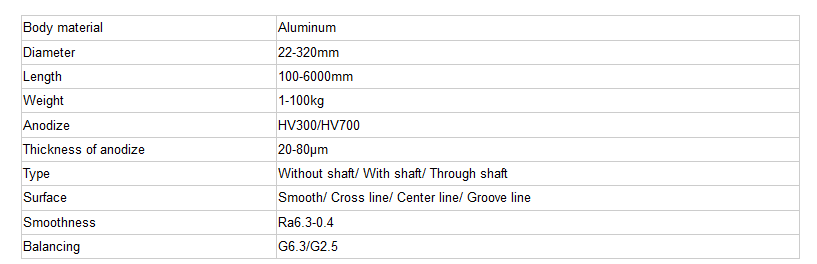

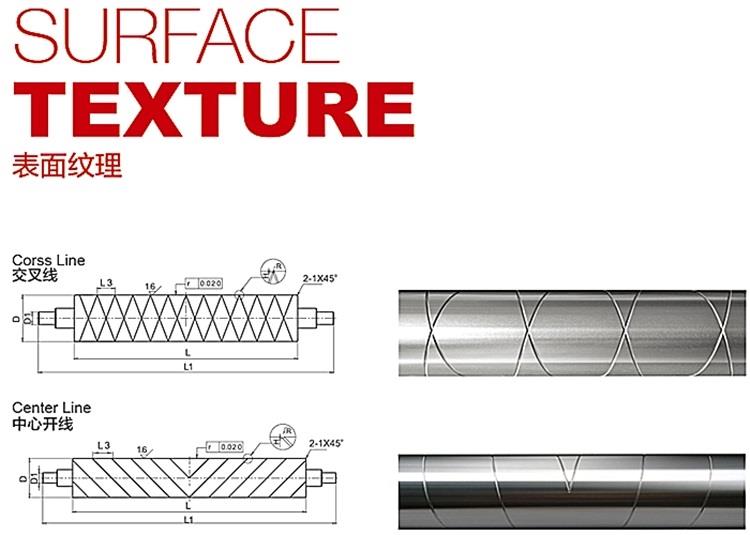

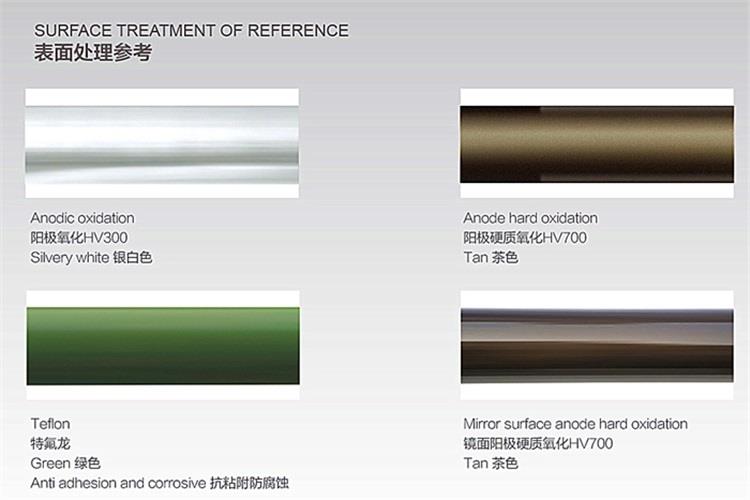

The aluminum guide is made of high-quality aluminum alloy. It has nine reinforcing ribs and a wall thickness of 5cm. The surface treatment is based on user requirements. It has ordinary oxidation, hard oxidation, Teflon, etc. to ensure its rigidity and wear resistance.

Application

Order Details

Item Name | Aluminum roller |

MOQ(Minimum Order Quantity) | 1PC |

Lead time | 10-15 days after receiving the deposit |

Calculated Weight | Need to count |

Package | Wooden Box/Pallet packing/according to clients's requirement and demand |

Price Term | EXW,FOB, CIF, etc |

| Payment term | TT,L/C,Western Union |

| Country of Origin | China |

Hot Tags: lightweight aluminum idler roller, China, manufacturers, suppliers, factory, quotation, pricelist, buy