Tension Systems

The fully automatic tension controller KTC-838A is a high-precision, multi-function, all-digital intelligent tension controller, which is combined with a tension detector to form a closed-loop tension control system. By receiving the signal transmitted by the LS series tension detector, after...

The fully automatic tension controller KTC-838A is a high-precision, multi-function, all-digital intelligent tension controller, which is combined with a tension detector to form a closed-loop tension control system. By receiving the signal transmitted by the LS series tension detector, after the internal intelligent PID operation processing, the actuator is adjusted to automatically control the tension of the unwinding, intermediate guiding and winding of the long-sized material. KTC-838A tension controller adopts a new graphic liquid crystal display, which shows clearer in Chinese and English. It also outputs 0~24VDC control voltage command for magnetic powder clutch/brake. It can also output 0~10V voltage signal to control inverter, servo motor or Other actuators perform high-precision tension control on the coil material. Can be widely used in printing, packaging, paper, cable, rubber and plastics, electronic batteries, textile printing and dyeing industries.

Automatic Tension Controller with Taper and Communication Function

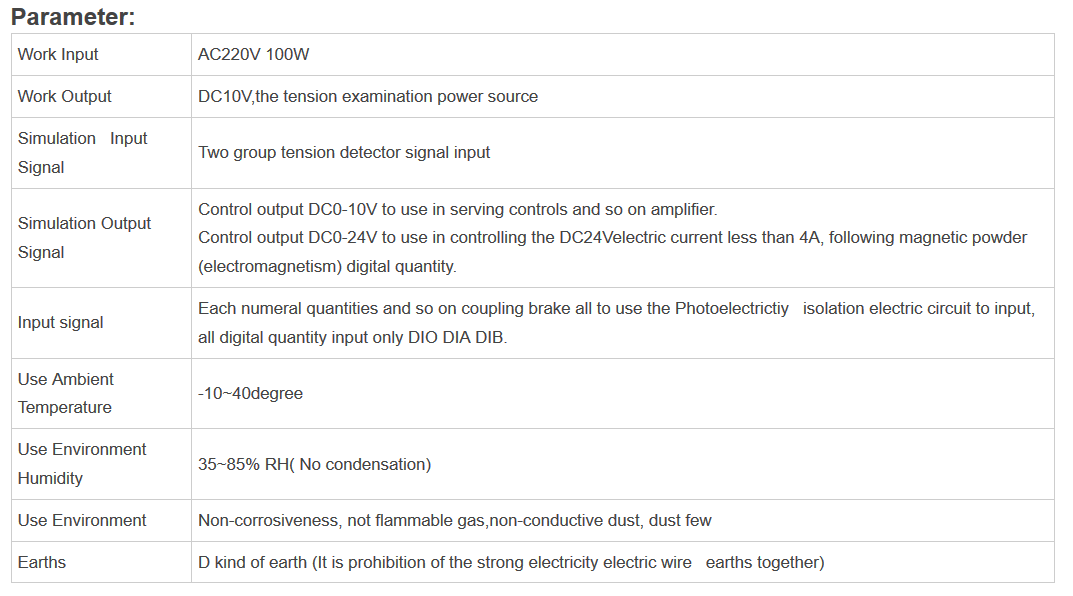

Operating Panel:

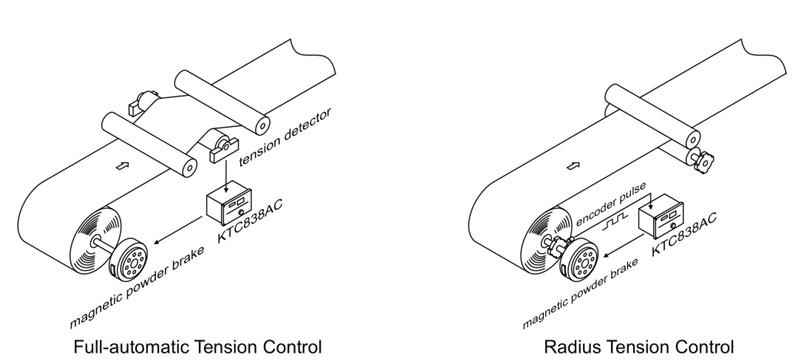

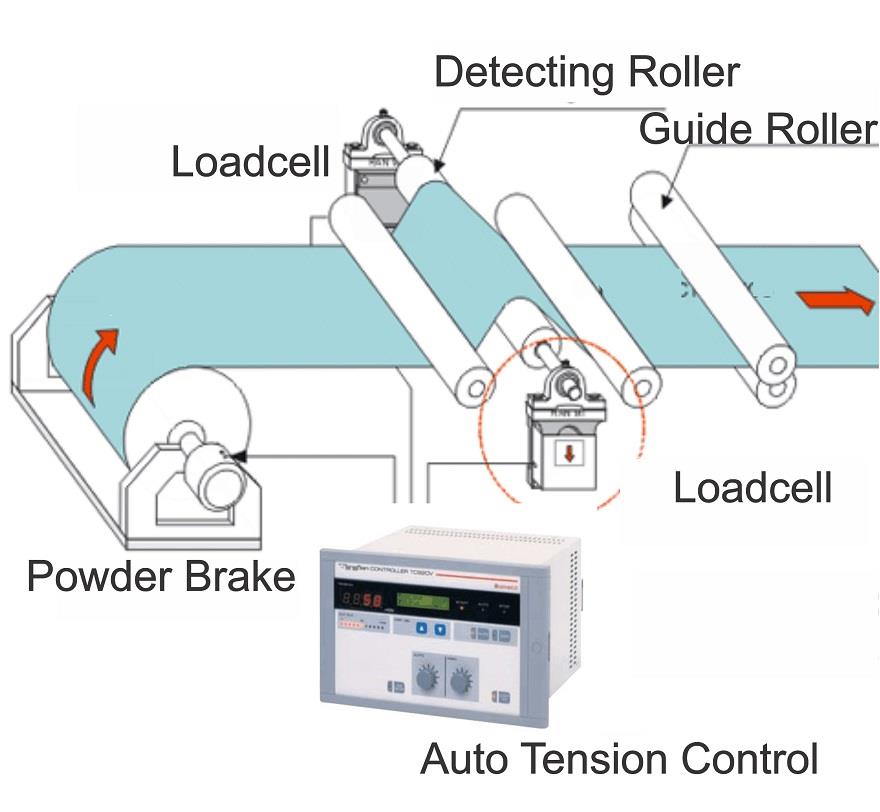

working principle:

1. The coil static magnetic powder clutch and the magnetic powder brake are automatic devices that control the input current and change the output transition.

2. When the coil is not energized, the input shaft rotates, and the magnetic powder is pressed against the inner wall of the clamp ring under the action of centrifugal force, and the output shaft is not in contact with the input shaft. At this time, it is in an idling state.

3. When the coil is energized, the magnetic powder generates a magnetic flux under the action of the magnetic force line, so that the output shaft and the input shaft become a rigid body and rotate, and a slip occurs when the overload occurs, and the working state is at this time. Thereby achieving the purpose of transmitting torque.

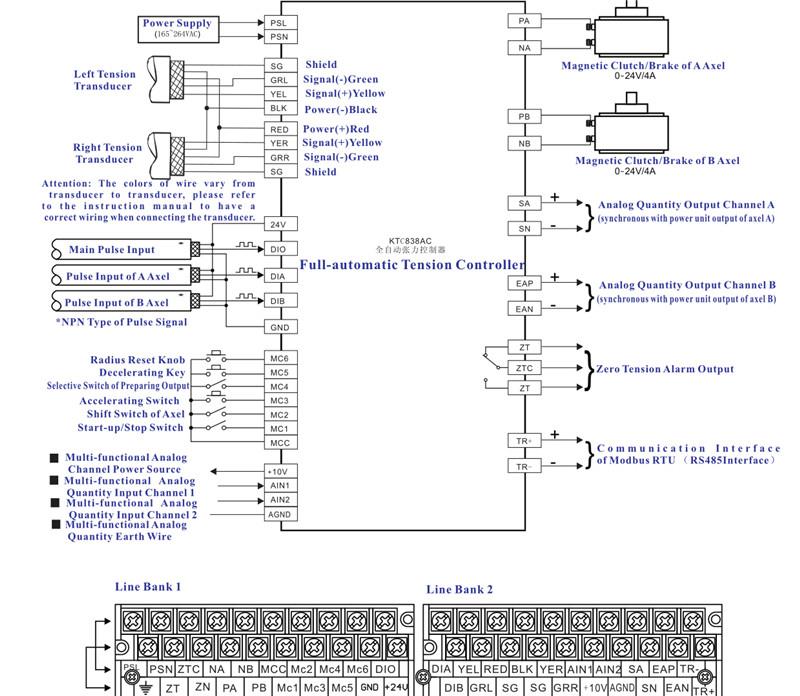

Wiring Diagram:

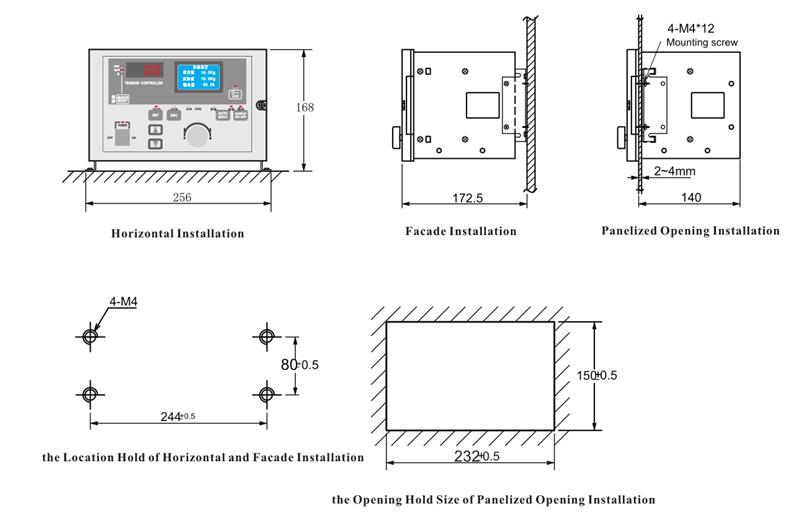

Installation:

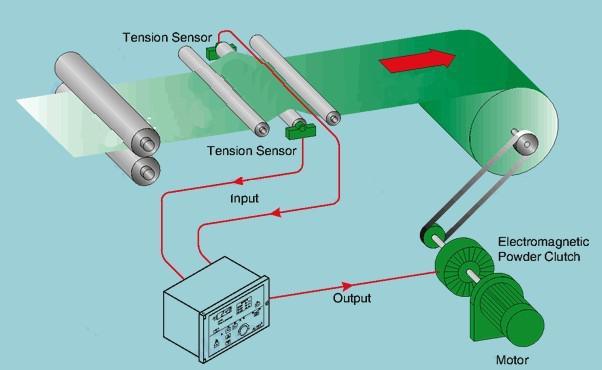

In lots of industries of business manufacturing, winding manipulate problems are regularly encountered. for instance, inside the production procedure of paper, textiles, plastic movie, electric twine, revealed remember, magnetic tape, metallic strip cord, etc., the unwinding and winding tension of the strip or wire is crucial to the great of the product, and regular anxiety manipulate is needed for this purpose. that is, the product is subjected to properly tension at some point of the winding procedure and stays unchanged for the duration of. if the tension is too huge, it will motive tensile deformation of the processed material; if the tension is too small, the stress between the layer and the layer of the wound material will be deformed, resulting in unwinding and affecting the processing best. in the strip take-up machine, the anxiety manage machine occupies an important role and it is pretty complicated.

The tension controller is a system evolved via a single chip microcomputer or some embedded devices and peripheral circuits. it is a manipulate tool that may directly set the anxiety value required to be managed, after which at once input the signal of the anxiety sensor as the anxiety feedback fee. after the deviation is received by means of evaluation, it is input to the controller along with pid for processing, and is output to the peripheral actuator for manage, and finally achieves the cause of small deviation and speedy gadget reaction.

A typical tension control system consists mainly of a tension controller, a tension reader, a tension detector, a magnetic powder brake and a clutch. The coil stationary magnetic powder clutch and the magnetic powder brake are automatic devices that control the input current to change the output transition. When the coil is not energized, the input shaft rotates, and the magnetic powder is pressed against the inner wall of the clamp ring by the centrifugal force, and the output shaft is not in contact with the input shaft. At this time, it is in an idling state. When the coil is energized, the magnetic powder generates a magnetic flux under the action of the magnetic force line, so that the output shaft and the input shaft become a rigid body and rotate, and a slip occurs when the overload occurs, and the working state is at this time. Thereby achieving the purpose of transmitting torque.

Tension control refers to the ability to permanently control the tension of a material as it is delivered on a device. This control must be effective for any speed of the machine, including acceleration, deceleration and constant speed of the machine. Even in the case of an emergency stop, there should be the ability to ensure that the cuts are not damaged.

Order Details

Item Name | KTC-838A Automatic Tension Controller with Taper and Communication |

MOQ(Minimum Order Quantity) | 1pc |

Lead time | 2 days after receiving the deposit |

Calculated Packing Size | 20cm*15cm*15cm,2kg/pc |

Package | Carton |

Price Term | EXW,FOB, CIF, etc |

Payment term | TT,L/C,Western Union |

Country of Origin | China |

Hot Tags: tension systems, China, manufacturers, suppliers, factory, quotation, pricelist, buy