Load Transducer

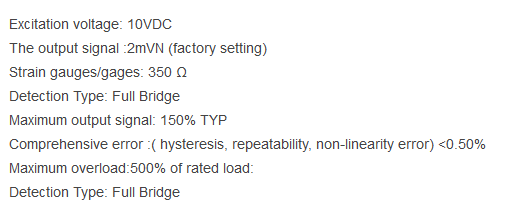

Tension sensors are very common in the industry, and tension sensors can be classified into different degrees of accuracy or grades depending on their overall performance. Specific accuracy levels govern the combination of certain parameters such as nonlinearity, hysteresis, temperature effects,...

Tension sensors are very common in the industry, and tension sensors can be classified into different degrees of accuracy or grades depending on their overall performance. Specific accuracy levels govern the combination of certain parameters such as nonlinearity, hysteresis, temperature effects, creep, and the like. In theory, certain system accuracy parameters are highly horizontally dependent on use, load introduction, and interference, such as overvoltage and surge maintenance.

LC Series Through-Hole Tension Detector

Installation:

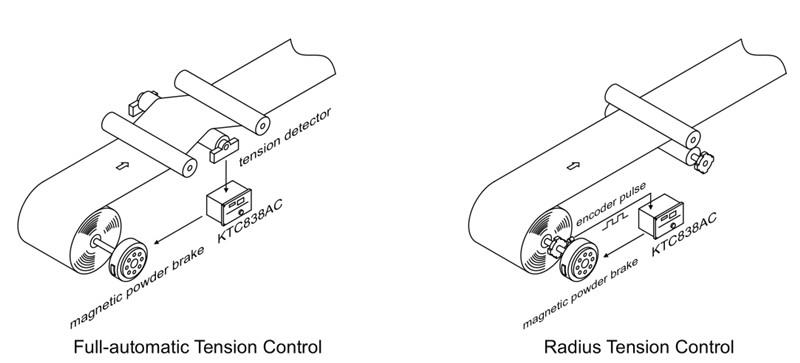

Tension sensor measurement and control

The most commonly used non-contact temperature measuring instrument is based on the basic law of black body radiation, called the radiation temperature measuring instrument. Radiation thermometry includes brightness methods (see optical pyrometers), radiation methods (see radiant pyrometers), and colorimetric methods (see colorimetric thermometers). All types of radiation temperature measurement methods can only measure the corresponding luminosity temperature, radiant temperature or colorimetric temperature. It is only the temperature measured by the black body (the object that absorbs all radiation and does not reflect light) is the true temperature. To determine the true temperature of an object, it is necessary to abort the correction of the surface emissivity of the material. The surface emissivity of the material depends not only on the temperature and wavelength, but also on the surface state, film and microstructure, so it is difficult to measure accurately. In automated consumption, it is often necessary to apply radiation temperature measurement to measure or control the surface temperature of certain objects, such as steel strip rolling temperature, roll temperature, forging temperature and temperature of various molten metals in a smelting furnace or crucible. . In these meticulous cases, the measurement of the surface emissivity of an object is quite difficult.

In the static weighing system (tension sensor pin sensor displacement sensor), the sum of the fixed load and the variable load should be no more than 60% of the total rated load of the sensor (sensor rated load × number of sensors). In the dynamic weighing system, the influence of the additional load caused by the impact should also be considered.

Sensor installation and attention matters

When designing the loading device and installing it, it should be ensured that the action line of the loading force coincides with the force axis of the sensor, so that the effects of the tilt load and the eccentric load are minimized. Select the rated load of the sensor to be used according to the sensor range in this description. The sensor housing, maintenance cover, and lead connectors are sealed and the user is not allowed to open. To prevent chemical corrosion. Vaseline should be used to apply the outer surface of the sensor during installation. Fields that should be protected from direct sunlight and drastic changes in ambient temperature should be equipped with protective or mitigation devices when they are unavoidable.

In order to prevent the large current from directly smashing through the sensor body and damaging the sensor to stop the welding operation after the sensor is installed, a bypass device made of a copper braided wire should be added to both ends of the sensor loading device as a last resort.

The cable of the sensor should be away from the strong power supply line or the place with pulse wave. When the competition cannot be avoided, the cable of the sensor should be inserted into the iron pipe separately, and the connection distance should be shortened as much as possible.

The cable should not be lengthened by itself. When it is really necessary to lengthen, it should be soldered at the joint and a moisture-proof sealant.

In places where high precision is used, sensors and meters should be used after 30 minutes of warm-up.

The sensor should be placed in a room with monotonic ventilation and no corrosive gas

Regarding the automatic measurement and control of the solid surface temperature, an additional mirror can be used to form a black body cavity together with the surface to be tested. The effect of additional radiation can improve the effective radiation and effective emission coefficient of the surface being measured. Applying the effective emission coefficient to the measured temperature to stop the corresponding correction, the final temperature of the measured surface can be obtained. The most typical additional mirror is a hemispherical mirror. The diffuse radiant energy of the measured surface near the center of the ball is reflected back to the surface by the hemispherical mirror to form additional radiation, so that ε is the surface emissivity of the material and ρ is the reflectivity of the mirror. As for the measurement of the true temperature of the gas and liquid medium, a method of inserting the tube of heat resistant material to a certain depth to form a black body cavity can be used. The effective emission coefficient of the cylindrical cavity after the medium reaches the thermal equilibrium is calculated. In the automatic measurement and control, this value can be used to stop the correction of the measured cavity bottom temperature (ie, the medium temperature) to obtain the true temperature of the medium.

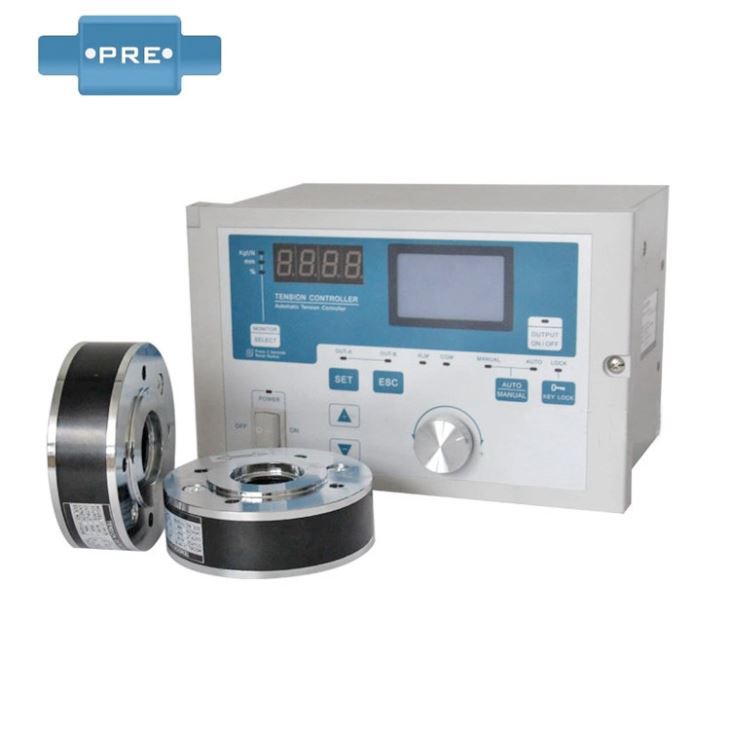

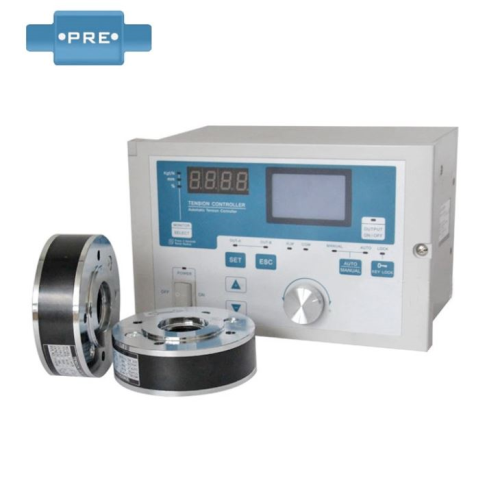

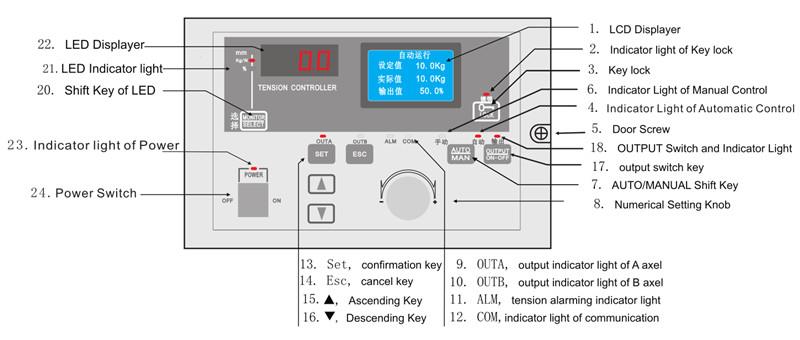

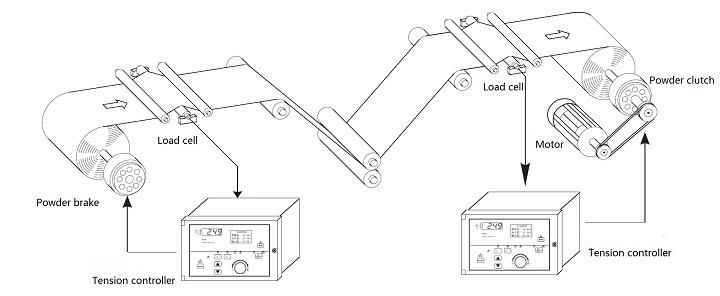

Automatic Tension Controller with Taper and Communication Function

Operating Panel:

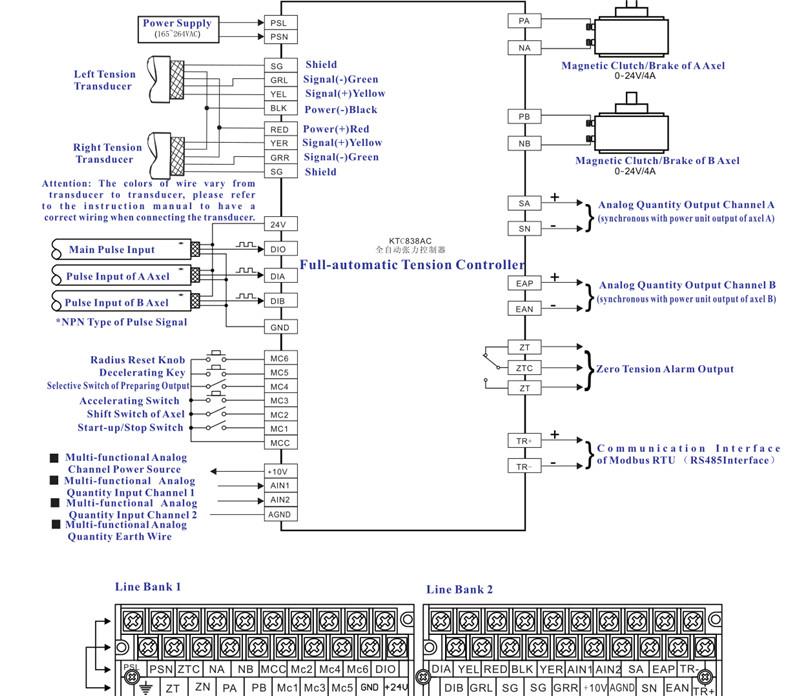

Wiring Diagram:

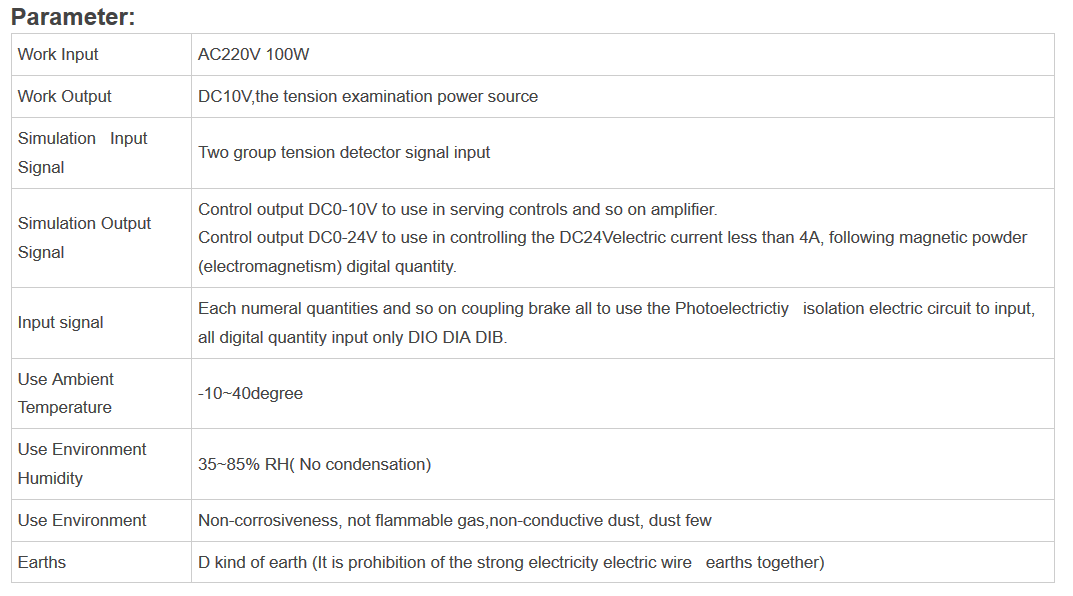

Installation:

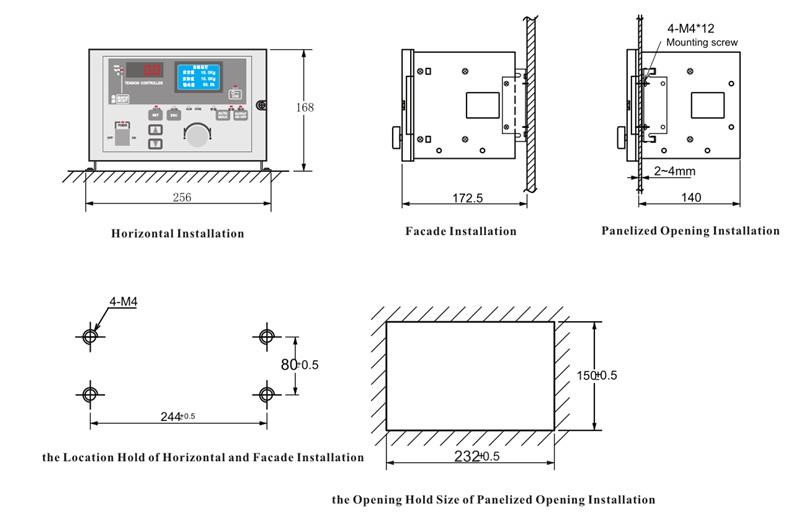

Application

Order Details

Item Name | LC Through-Hole Tension Detector KTC-838A Automatic Tension Controller with Taper and Communication |

MOQ(Minimum Order Quantity) | 1Set |

Lead time | 5-7 days after receiving the deposit |

Calculated Packing Size | 20cm*10cm*10cm, 4kg/Pc 20cm*15cm*15cm,2kg/pc |

Package | Carton |

Price Term | EXW,FOB, CIF, etc |

Payment term | TT,L/C,Western Union |

Country of Origin | China |

Hot Tags: load transducer, China, manufacturers, suppliers, factory, quotation, pricelist, buy