Curved Flattening Roller

1, the structure principle Mainly composed of curved mandrel, rolling bearing assembly, rubber sleeve, end sleeve, bearing and adjusting wheel. The curved roller bends the shaft into the required arc shape, and the bearing is mounted on the shaft at a certain interval. The rubber sleeve is...

1, the structure principle

Mainly composed of curved mandrel, rolling bearing assembly, rubber sleeve, end sleeve, bearing and adjusting wheel.

The curved roller bends the shaft into the required arc shape, and the bearing is mounted on the shaft at a certain interval. The rubber sleeve is sleeved on the bearing to form a roller having an arc shape and a rubber sleeve rotating around the shaft.

The direction of the arc can be adjusted by the hand wheel on the shaft seat. When the rubber sleeve rotates around the bending axis, the rubber surface can be unfolded and retracted. When the substrate touches the roller surface from the concave arc, it leaves when running to the convex arc. The roller surface of the curved roller only rotates in a direction parallel to the longitudinal direction, and the other points on both sides of the center of the roller surface rotate at an angle to the longitudinal direction, thereby causing the substrate to be pulled to both sides. Stretching, the substrate is flattened.

2, characteristics

● High line speed, low jitter, no noise

● Small rotating torque and can withstand large pulling force

● Good sealing performance, waterproof, acid and alkali resistance

● Safe and durable, easy to install and debug

● There is a unique flattening function for the substrate to appear in the middle of the tight side of the two sides or the loose side of the middle.

The flattening ability is relatively small, the angle of the substrate wrapping roller should not be too large or the tension is too large, otherwise the film-based substrate may be permanently deformed, the paper substrate may be broken, and the cloth substrate may be bent in the weft direction. It is sometimes necessary to adjust the direction of the curvature in time depending on the condition of the substrate.

The curved flattening roller is widely used in textile, printing and dyeing, printing, papermaking, film, packaging and other industries. It is a variety of products with wide application range and large dosage.

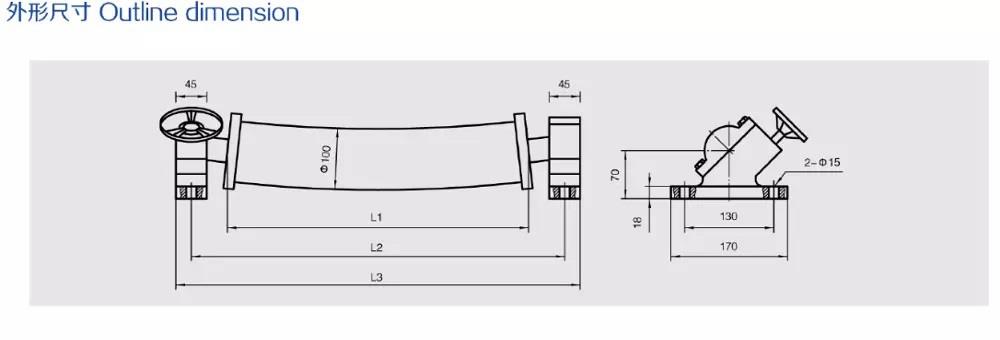

Roller surface diameter | 80, 100, 125, 150 |

Roller length | 200-3600mm |

Substrate roller angle | 15°-30° |

Roller line speed | <300m/min |

Rubber variety | Butadiene rubber, EPDM rubber, silicone |

5, ordering instructions

please note

● Roller length

● Mandrel length

● Roller diameter

● Line speed

Order Details

Item Name | Curved flattening roller |

MOQ(Minimum Order Quantity) | 1Pc |

Lead time | 15-18 days after receiving the deposit |

Calculated Weight | Need to count |

Package | Wooden Box |

Price Term | EXW,FOB, CIF, etc |

Payment term | TT,L/C,Western Union |

Country of Origin | China |

Hot Tags: curved flattening roller, China, manufacturers, suppliers, factory, quotation, pricelist, buy