Tubing Roller

The aluminum guide roller has high strength, low resistance, light weight, flexible rotation, no rust, wear and corrosion resistance, and is especially suitable for precision machinery industry such as printing, packaging, plastics, electronic batteries and various coil processing industries....

The aluminum guide roller has high strength, low resistance, light weight, flexible rotation, no rust, wear and corrosion resistance, and is especially suitable for precision machinery industry such as printing, packaging, plastics, electronic batteries and various coil processing industries.

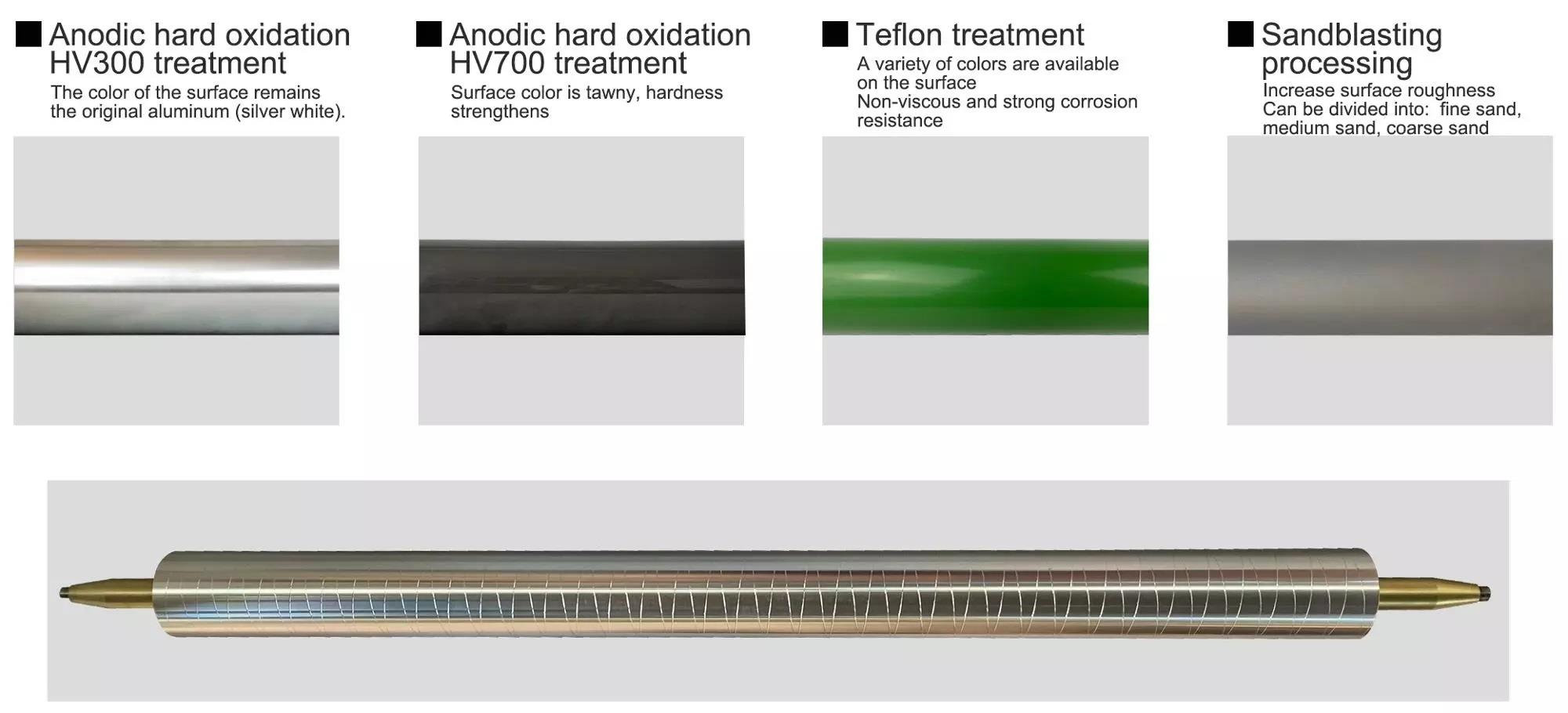

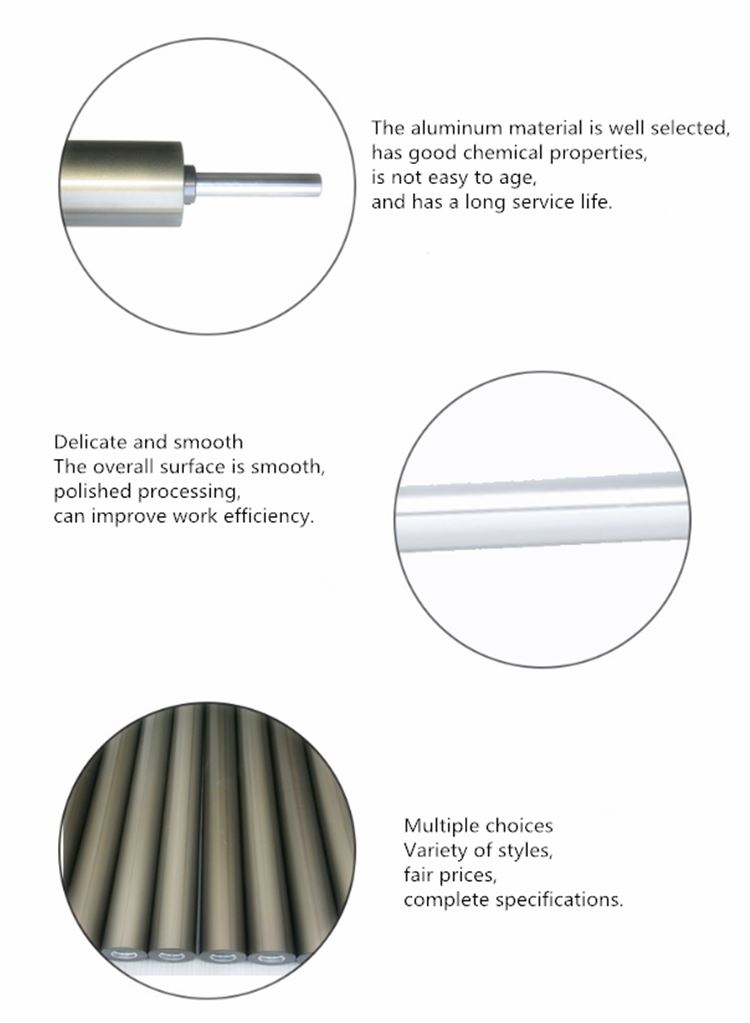

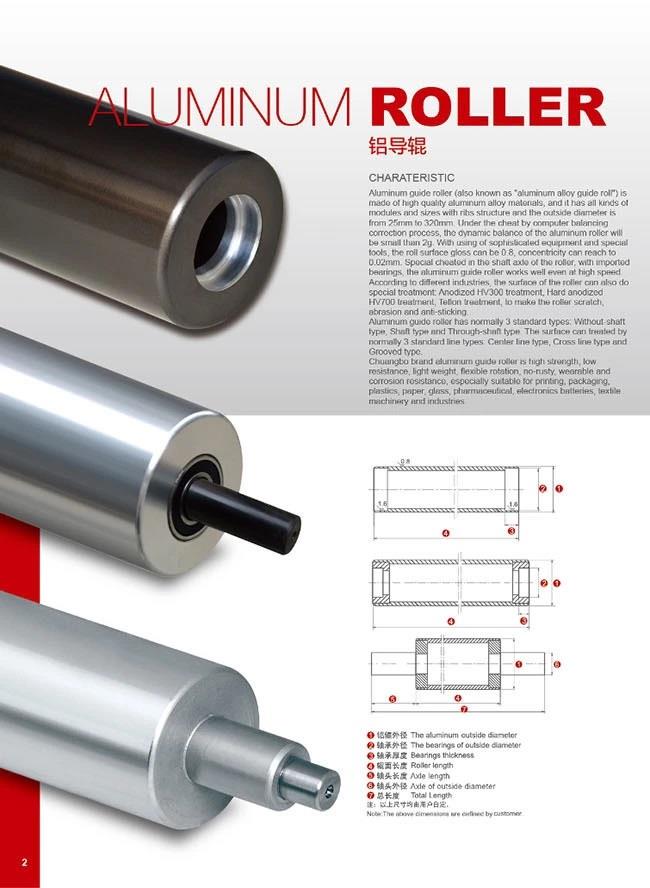

The aluminum guide roller is made of high-quality aluminum and is made by advanced processing technology. The surface is anodized HV300 (white) or HV700 (brown), the roll body finish is 0.8; the school balance is G2.5; the aluminum tube is generally 8- 10 ribs; can be customized according to customer requirements, groove roller, cross-line aluminum guide roller, center open aluminum guide roller, flower roller, anilox roller, cooling roller.

The aluminum alloy aluminum guide roller is made of high-quality aluminum alloy extrusion. It has nine reinforcing ribs and 5cm wall thickness for strengthening. The wheel surface adopts new technology and the anode is hardened to ensure its rigidity and wear resistance. Correction, so that the balance is up to 2g, the above technology is currently the first in China. Using Taiwan's special tools and measuring tools, the surface roughness of the rollers is up to 0.8 and the coaxiality is 0.02mm. The reasonable shaft connection method can easily run freely and never change at any running speed. This product has high strength, low resistance, corrosion resistance, light weight, smooth rotation and no rust. It is the first choice in the printing machinery system.

O.D(mm) | I.D(mm) | Wall Thickness | Stiffener |

Ф32 Ф33 Ф40 | Ф24 Ф27 Ф34 | 4:00 3:00 3.00 |

8 |

Ф40.5 Ф42.5 serrated roller Ф43.8 | Ф31 Ф30 Ф34.5 | 5.00 4.50 5.00 | |

Ф47 Ф50.5 Ф51 with groove | Ф40.8 Ф40.5 Ф38 | 3.00 5.00 6.50 | 8

6 |

Ф55 Ф58.5 Ф61 | Ф46.5 Ф51.5 Ф51 | 4.50 3.50 4.90 | 6 8 6 |

Ф70 serrated roller Ф71 Ф71 | Ф46 Ф63.2 Ф61 | 7.20 4.50 3.50 |

8 7 |

Ф74.5 Ф75.5 Ф80 | Ф60 Ф66 Ф73 | 7.20 4.50 3.50 |

8 8 |

Ф81 Ф81 Ф80 | Ф72.5 Ф71 Ф69 | 4.30 5.00 5.50 | 8 8 8 |

Ф90 Ф99 Ф101 | Ф81 Ф90.5 Ф92 | 4.50 4.30 4.50 | 8 8 7 |

Ф101.5 Ф101 Ф101 | Ф91.5 Ф89 Ф86.3 | 4.50 11.00 11.00 | 7 8 8 |

Ф111 Ф115 Ф116 | Ф102 Ф93 Ф94 | 4.50 11.00 11.00 |

7 8 |

Ф120.5 Ф121.5 Ф130.5 | Ф105.5 Ф111.5 Ф118 | 7.50 5.00 6.25 |

9 |

Ф140 Ф145 Ф151.5 | Ф120 Ф123 Ф139.5 | 10.00 11.00 6.20 | 8 7 8 |

Ф151.5 Ф153 Ф162 | Ф131.5 Ф121 Ф148 | 10.00 11.00 7.00 |

9 |

Ф184 Ф203 | Ф168 Ф179 | 8.00 12.00 | |

Ф150.5 Ф151 Ф200 Ф320 | Ф136.5 Ф140 Ф186 Ф296 | 7.00 5.50 7.00 12.00 |

10 |

With roller: applicable range for each conveying occasion.

Conical roller: suitable for conveying, curved conveyor, rail machine.

Double grooved roller: suitable for hardware, electronics, conveyor.

Roller for car: Scope of application: machinery, food, electronics, wood, mining, etc.

Power roller: The scope of application is applicable to all kinds of power and non-power conveyors.

Single-chain roller: Applicable to all types of power and non-powered conveyors.

Unpowered roller: Scope of application of food, tobacco, medicine, rubber, etc.

Metal unpowered cone roller: Scope of application Food, tobacco, medicine, rubber, etc.

Straight tube taper sleeve without power cone roller, straight tube rubberized non-power cone roller: Scope of application / transport / transmission / traction / power.

After the roll is formed, it needs surface treatment or coating such as painting, galvanizing, TEFLON spraying, rubber coating, chrome plating, ceramic spraying and oxidation for the purpose of rust prevention, corrosion resistance, wear resistance and support.

Classified by size, aluminum guide rolls have large rolls such as papermaking machinery (up to 10 meters in length and 1500mm in diameter), and there are small flat rollers for belt conveyors on automatic assembly lines (generally in 1). Within the length of the meter, the diameter is also within 159mm)

According to the action, the aluminum guide roller has a roller on the digital laser printer to ensure the transmission accuracy, and a calender roller on the papermaking machine that functions as a pressure filter, and has a support roller that does not require high dimensional accuracy. There are rollers for heat exchange, and rollers for heavy pressure filtration, which are not listed.

Roller diameter selection: 25mm, 32mm, 38mm, 42mm, 50mm, 57mm, 60mm, 76mm, 80mm, 89mm. Roller material selection: carbon steel galvanizing, carbon steel chrome plating, carbon steel rubber, aluminum alloy, stainless steel, ABS, etc.

Roller type selection: no power roller, single chain roller, double chain roller, "O" belt roller, conical roller, grooved roller. Roller fixing method: spring press type, inner shaft type, full flat type, through shaft pin hole type.

Application

Aluminum roller installation and commissioning

1, loading and unloading

The printing plate roller should be matched with the bearing during installation to ensure a certain degree of precision and cleanliness. The aluminum roller should be lightly handled and should not collide with the shaft head and the rubber layer to avoid damage, bending and damage of the rubber layer.

2, lubrication

Printed roller heads and bearings should always be effectively lubricated. If the lubrication is poor, it will cause the wear of the printing plate aluminum roller roller head and the bearing, and the gap will increase, resulting in uneven printing on the ink. At the same time, the printing bar marks may be caused by defects such as the printing plate jumping and sliding. If there is no effective lubrication for a long time continuous operation, the bearing and the shaft core will be heated, causing the rubber surface of the printing plate to be thermally expanded and worn, so that the rubber surface of the two heads is pocked, glued and cracked.

3, debugging

The pressure between the printing plate roller and the aluminum roller and the printing plate should be adjusted according to the elasticity and hardness of the rubber and its role in the printing process. Generally, the feeler gauge of O.15~O.20mm is used (the feeler gauge should be lubricated to avoid The test is performed on the damaged rubber surface. The radial contact pressure of the printing plate roller must be uniform. Otherwise, long-term operation will cause the printing plate roller at the end of the pressure to produce pitting, gelation, cracking, and opening of the rubber.

Shipping

Order Details

Item Name | Aluminum roller |

MOQ(Minimum Order Quantity) | 1PC |

Lead time | 10-15 days after receiving the deposit |

Calculated Weight | Need to count |

Package | Wooden Box/Pallet packing/according to clients' demand |

Price Term | EXW,FOB, CIF, etc |

| Payment term | TT,L/C,Western Union |

| Country of Origin | China |

Hot Tags: tubing roller, China, manufacturers, suppliers, factory, quotation, pricelist, buy