Manufacturing Of Shaft

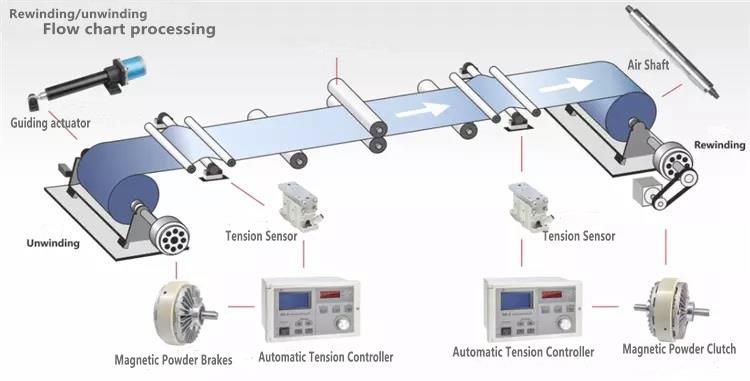

Talking about the method of exhausting the exhaust input of the air shaft Use the braking force and the driving force to balance the shaft as much as possible. The air hydraulic pneumatic brake port should be located above the brake body to facilitate the discharge of air. The position of the...

Talking about the method of exhausting the exhaust input of the air shaft

Use the braking force and the driving force to balance the shaft as much as possible. The air hydraulic pneumatic brake port should be located above the brake body to facilitate the discharge of air. The position of the supercharger and the oil pressure source should be higher than the brake, and the closer to the brake, the better. The brake disc should be placed at the center of the brake chuck. The deviation should be less than 0.2mm. The amplitude of the brake disc should be controlled within 0.1mm. Before using the air pressure pneumatic brake, the air in the brake body should be completely discharged, the exhaust port bolts should be loosened, and a transparent rubber hose should be placed.

It is an excellent appliance that guarantees the safety of people and the machine itself. Because it not only has strong rigid characteristics, but also plays a role in reducing the looseness of the machine screws. In order to enhance the service life of the safety clamp, it also has obvious advantages in structure, and its excellent precision shaft port design provides a large bearing capacity for the entire safety protection program. When the number of rotations exceeds the allowable number of rotations, the vibration becomes large, and depending on the occasion, damage or scattering may occur in a very dangerous state. Be sure to use it under the permissible number of rotations and set the protective cover. The friction plate used in the inflation shaft should not be wet or greased, otherwise it will affect the torque or work performance.

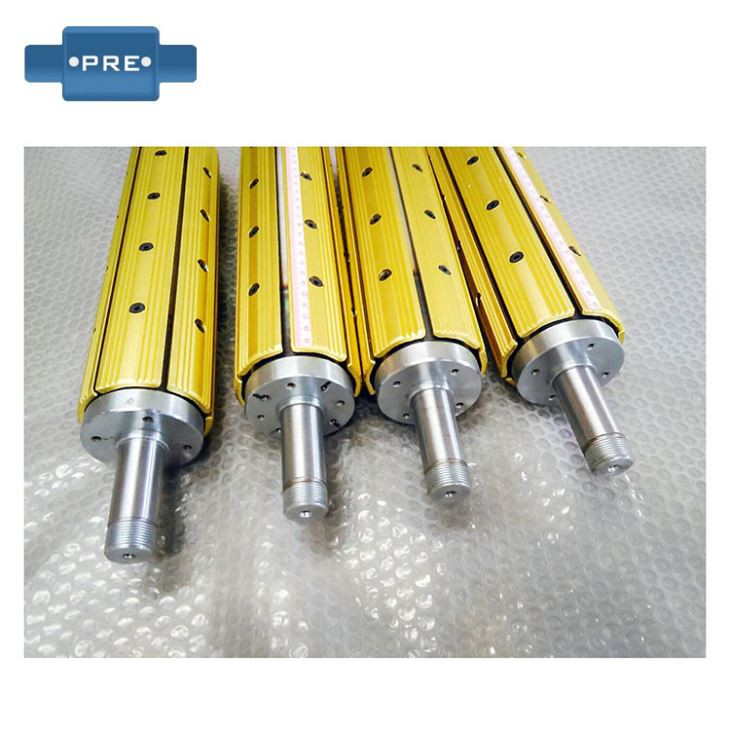

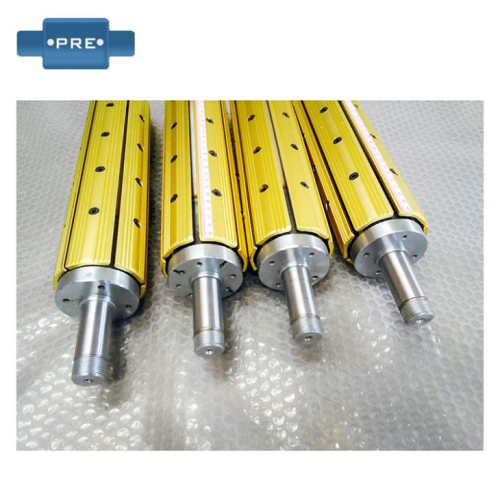

The ordinary air expansion shaft consists of two departments: the air expansion shaft and the long expansion tube.

Technique parameter

Model | Inner Diameter of Paper Tube | Shaft Diameter Before Expanding | Shaft Diameter After Expanding |

1" Shaft | Φ25.4mm | Φ24.5mm | Φ27.5mm-Φ28mm |

1.5" Shaft | Φ38mm | Φ37mm | Φ41mm |

2" Shaft | Φ50mm | Φ49mm | Φ53mm |

3" Shaft | Φ76.2mm | Φ74mm-Φ74.5mm | Φ82mm |

4" Shaft | Φ102mm | Φ100mm | Φ108mm |

6" Shaft | Φ152.4mm | Φ150mm | Φ158mm |

8" Shaft | Φ203.2mm | Φ200mm | Φ210mm |

10" Shaft | Φ254mm | Φ250mm | Φ260mm |

12" Shaft | Φ304.8mm | Φ300mm | Φ312mm |

Functional requirements for the air shaft nozzle:

Since the application of the inflation shaft is relatively high in terms of gas pressure, there are many requirements for the gas nozzle of the inflation shaft. Let us take a look.

First of all, the sealing of the gas nozzle is good, and it can ensure that the gas nozzle is filled and discharged during the two-second inflation time of the inflation shaft. And the internal air pressure is ensured, otherwise it will not be able to supply useful air pressure.

Secondly, the quality of the gas nozzle is good. Most of the gas nozzle materials use copper as the basic data. Because of the pressure of 3-4 atmospheres, the pressure resistance is also relatively high, and the production is also convenient.

Finally, the application of the gas nozzle needs to be noticed. Since only the gas-filling rod is facing the gas nozzle on the inflation shaft, the inflation shaft is successfully inflated, so the requirement for the rapid filling and exhausting function of the gas nozzle is relatively high.

Packing

Order Details

Item Name | Air shaft |

MOQ(Minimum Order Quantity) | 1Pc |

Lead time | 15-18 days after receiving the deposit |

Calculated Weight | Depend on dimension |

Package | Carton/Wooden Box |

Price Term | EXW,FOB, CIF, etc |

Payment term | TT,L/C,Western Union |

Country of Origin | China |

Hot Tags: manufacturing of shaft, China, manufacturers, suppliers, factory, quotation, pricelist, buy