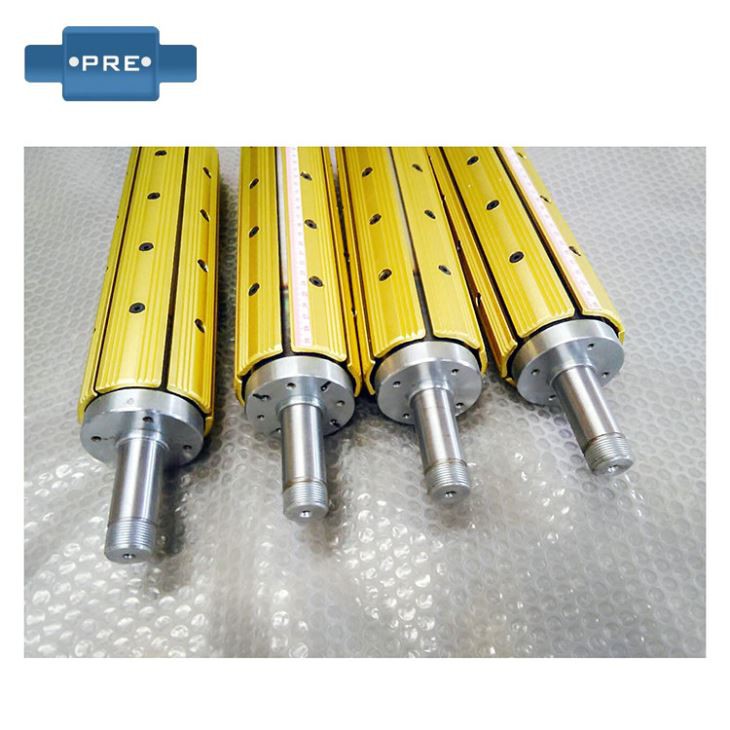

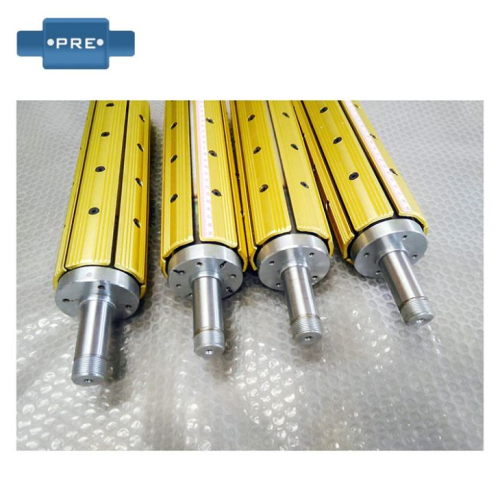

Slitting Machine Shaft

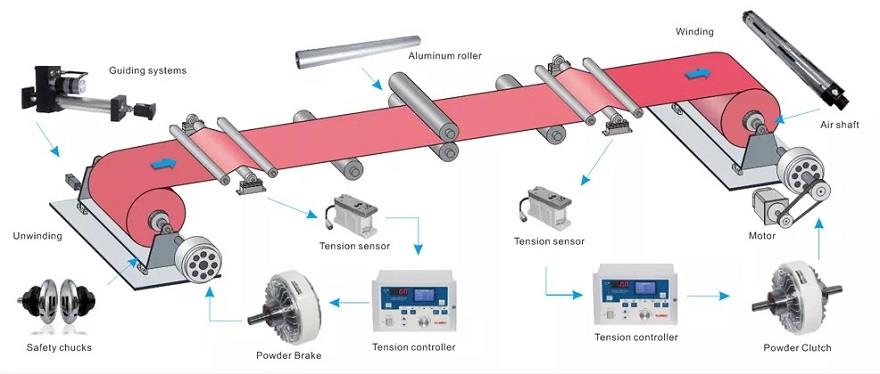

The use of the air-expansion shaft is versatile: the air-expansion shaft can be applied to any machine that has a winding and unwinding. Suitable for printing equipment: drying machine, flexo printing machine, gravure machine, trademark printing machine and so on. Suitable for other mechanical...

The use of the air-expansion shaft is versatile: the air-expansion shaft can be applied to any machine that has a winding and unwinding.

Suitable for printing equipment: drying machine, flexo printing machine, gravure machine, trademark printing machine and so on. Suitable for other mechanical equipment: coating machine, leather machine, setting machine, embossing machine, slitting machine, die cutting machine, rewinding machine, rewinding machine, paper tube machine, laminating machine, laminating machine, The use of blown film machine, foaming machine, laminating machine, embossing machine, paper machine, non-woven machine, cloth inspection machine, bronzing machine, battery equipment and other related machinery.

The integral metal frame excavates a box-type window at the fixed end of the cantilever mandrel operating side to ensure the structural rigidity of the printing platform. The bearing seat is mounted on the inside of the movable steel block, and the steel block is made of high-precision ball wire. The rod is driven, and the moving position of the screw is on the center line of the plate mandrel. Linear guides are respectively installed at the upper and lower ends of the box window to fix the movable steel block, thereby ensuring the stability of the printing platform in high-speed operation.

In this design, the fixing of the mandrel is completely automatic, and the movement of the entire screw and the locking of the shaft end eliminate the human factor. The moving steel block is fixed to the frame by two upper and lower linear guide rails, and since the screw rod moves on the center line of the plate roller mandrel, the thrust of the center impression cylinder against the plate roller and the driving force along the direction of the ball screw are both effective. At the center of the plate mandrel, only a small partial pressure is formed, and since the force load acts only on the center of the plate mandrel, there is no torque on the support frame.

Technique parameter

Model | Inner Diameter of Paper Tube | Shaft Diameter Before Expanding | Shaft Diameter After Expanding |

1" Shaft | Φ25.4mm | Φ24.5mm | Φ27.5mm-Φ28mm |

1.5" Shaft | Φ38mm | Φ37mm | Φ41mm |

2" Shaft | Φ50mm | Φ49mm | Φ53mm |

3" Shaft | Φ76.2mm | Φ74mm-Φ74.5mm | Φ82mm |

4" Shaft | Φ102mm | Φ100mm | Φ108mm |

6" Shaft | Φ152.4mm | Φ150mm | Φ158mm |

8" Shaft | Φ203.2mm | Φ200mm | Φ210mm |

10" Shaft | Φ254mm | Φ250mm | Φ260mm |

12" Shaft | Φ304.8mm | Φ300mm | Φ312mm |

The air expansion shaft and the air expansion sleeve are extremely convenient and quick to use. Only the self-prepared air source is needed. The air pressure is controlled within the range of 6-8kg/cm2. When the external components (such as a round paper tube) need to be locked, as long as the air is inflated. The handle can be completed by inflating the air nozzle on the inflation shaft, and the key bar will protrude against the external component (such as a circular paper tube). When the air shaft is to be repaired, the paper tube is unloaded, and the air is pressed by hand. The sliding air core on the mouth is deflated, the key strip will return to its original appearance, and the external parts (such as a round paper tube) can be taken out.

1. Neat: tools, workpieces, and accessories are placed neatly; safety protection devices are complete; line piping is complete.

2. Cleaning: Clean the inside and outside of the equipment; all sliding surfaces and screws, gears, racks, etc. are free of oil and no bumps; all parts are not leaking oil, no air leakage, no leakage; the garbage is cleaned.

3. Lubrication: Oil on time, oil quality, oil quality meets requirements; oil pot, oil gun, oil cup, linoleum, oil line are clean and complete, oil mark is bright, oil circuit is smooth.

4. Safety: Analysis of the air-expansion shaft maintenance factory, implementation of the fixed-machine setting and handover system; familiar with the equipment structure and compliance with operational procedures, rational use of equipment, careful maintenance of equipment, to prevent accidents.

The inflatable shaft is suitable for striping, printing, rewinding, coating, laminating and other mechanical cooperation that requires high roundness or surface winding. It is a special type of winding and unwinding, that is, the axis that can be raised by the surface after high pressure inflation (the key bar), and the axis that the surface part (referring to the key bar) is quickly retracted after deflation is called the inflation axis.

Its name is diversified, also known as pneumatic shaft, expansion shaft, inflation shaft, air expansion roller, inflation shaft, pressure shaft, air expansion roller, etc., although the name is more, but the working principle is the same. Inflatable shaft, inflatable sleeve use It is extremely convenient and fast. It only needs to be self-contained. The air pressure is controlled within the range of 0.5-0.8 MPa. When it is necessary to lock the external parts (such as a round paper tube), as long as the air gun is facing the air nozzle on the inflation shaft. The inflation can be completed, and the key bar will protrude against the external parts (such as a circular paper tube). When the paper is unloaded, press the sliding air core on the air nozzle to deflate, and the key bar will return to The original appearance, external components (such as a circular paper tube) can be taken out of the professional production of inflatable shaft, maintenance of the inflatable shaft, the principle of the inflatable shaft, although the inflation shaft is called, but the working principle is the same. The inflatable sleeve is extremely convenient and quick to use. It only needs to be self-contained. The air pressure is controlled within the range of 0.5-0.8 MPa. When the external components (such as a circular paper tube) need to be locked, as long as the air gun is inflated. The air nozzle on the shaft can be inflated, and the key bar will protrude against the external parts (such as a round paper tube). Hand pressing the slide core gas, i.e. the gas mouth deflated, will return to the original spline way, external components (such as a circular paper tube) can remove air shaft specializing in the production, repair air shaft,

Packing

Order Details

Item Name | Slitting machine shaft/Air shaft |

MOQ(Minimum Order Quantity) | 1Pc |

Lead time | 15-18 days after receiving the deposit |

Calculated Weight | Depend on dimension |

Package | Carton/Wooden Box |

Price Term | EXW,FOB, CIF, etc |

Payment term | TT,L/C,Western Union |

Country of Origin | China |

Hot Tags: slitting machine shaft, China, manufacturers, suppliers, factory, quotation, pricelist, buy