Web Aligner Manufacturer

The high-precision, high-speed, high-efficiency coil material automatic processing process of the correction system has higher and higher requirements for the control of the lateral position of the coil. Equipped with a high-performance automatic guide system is the key to improving the...

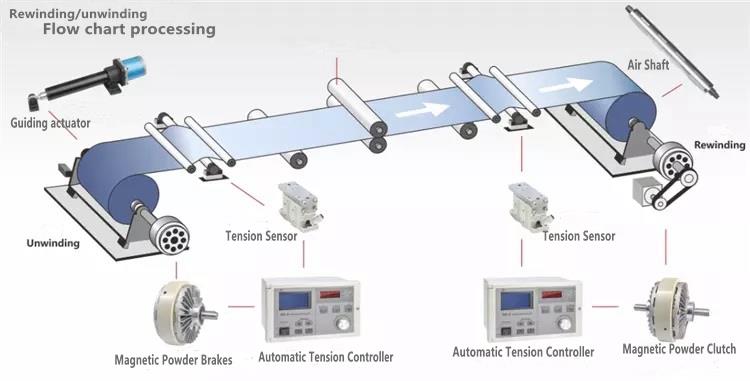

The high-precision, high-speed, high-efficiency coil material automatic processing process of the correction system has higher and higher requirements for the control of the lateral position of the coil. Equipped with a high-performance automatic guide system is the key to improving the production capacity and yield of coils. The coil will produce lateral displacement (running deviation) during travel, unwinding and winding, so the guide system can be installed in the above three positions to control the precise passing of the coil.

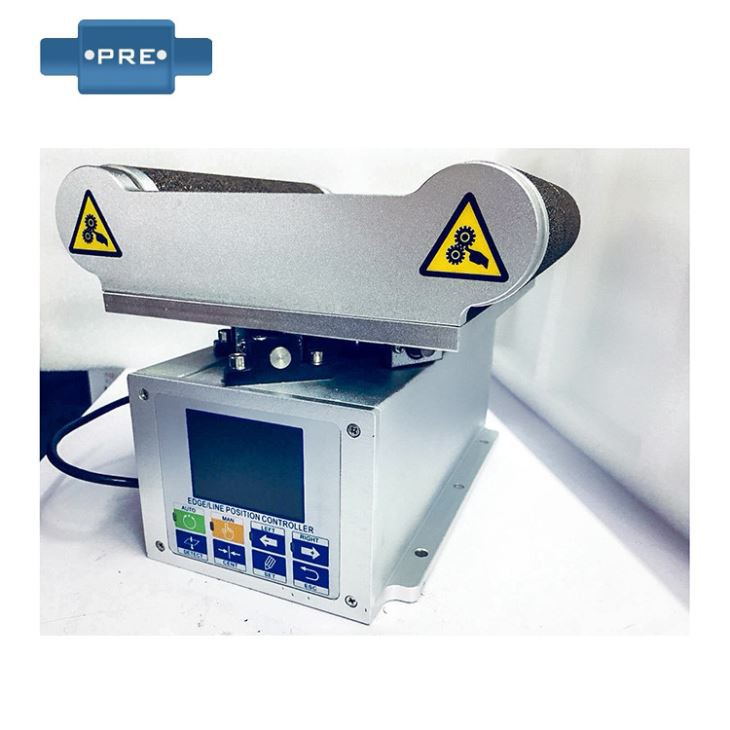

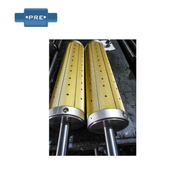

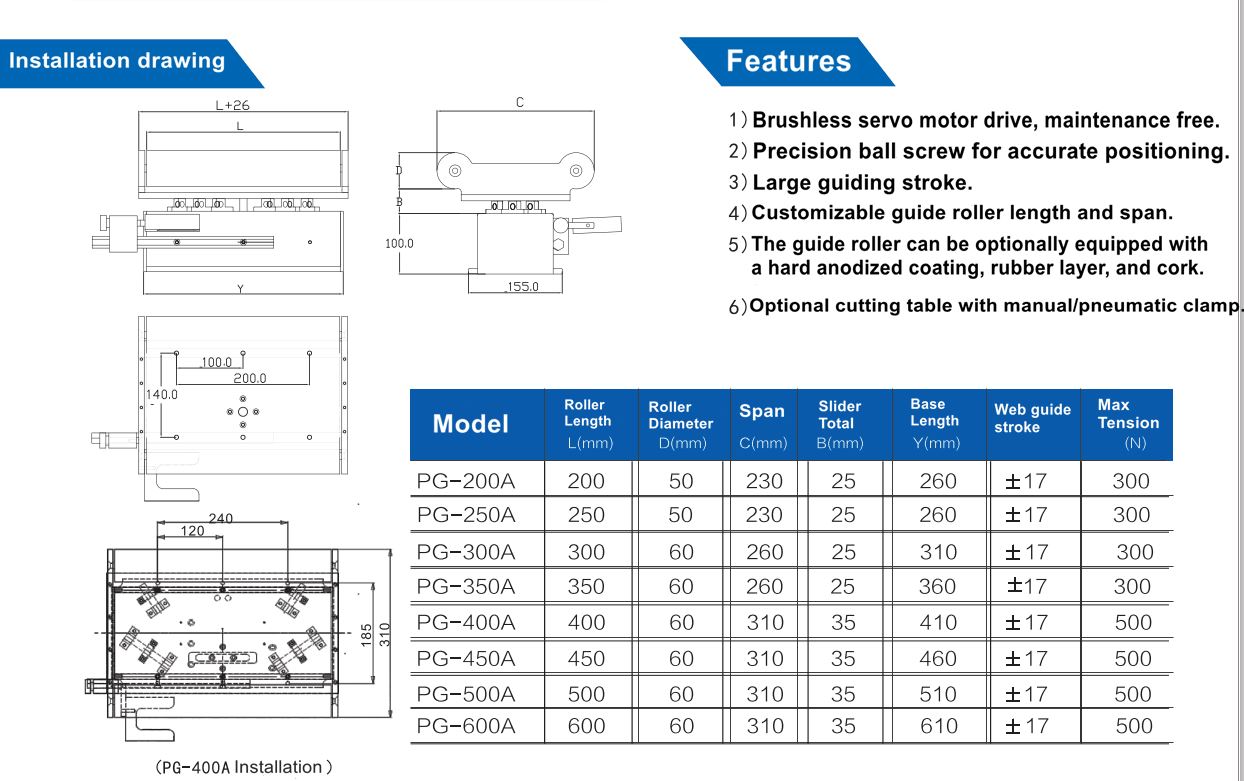

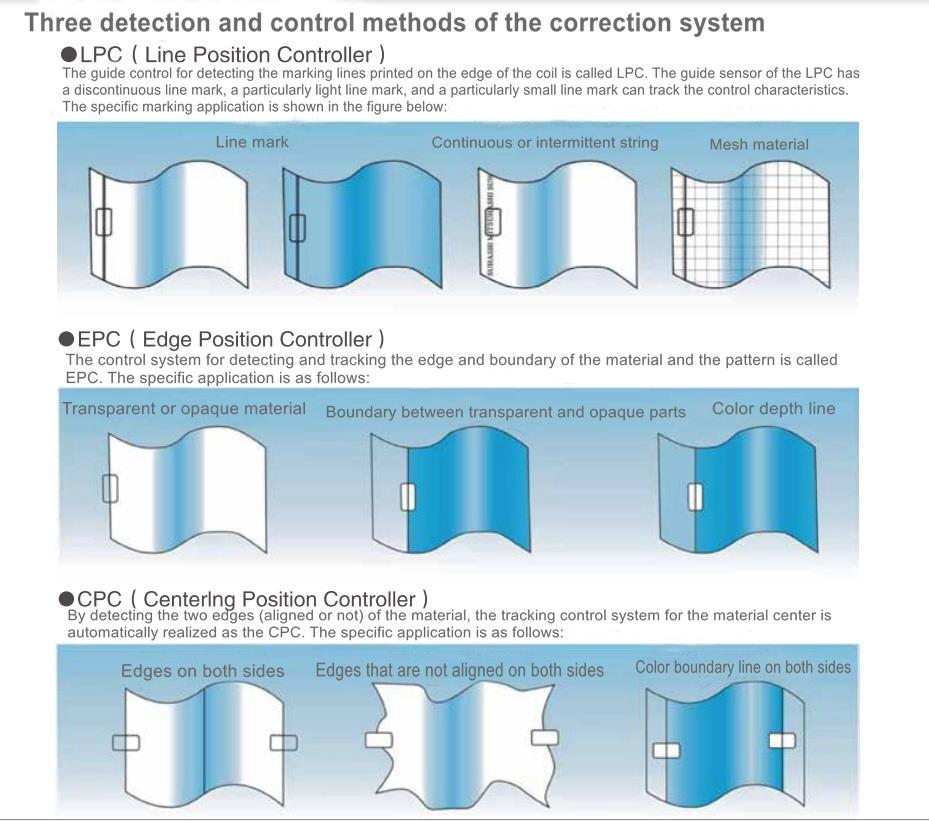

The system uses high-speed microprocessor, digital, modular, intelligent circuit design; advanced programming, user-friendly interface, LCD screen display; high-performance components and perfect circuit protection design to make the system run continuously and stably; control system response The time is less than 0.01 seconds; the accuracy of the system itself is up to 0.01mm. During the material winding process, the position of the edge or line is detected by the photoelectric sensor to pick up the edge guide frame or line position deviation signal. Then, the position deviation signal is transmitted to the photoelectric guide controller for logic operation, and a control signal is sent to the mechanical actuator to drive the mechanical actuator to correct the serpentine deviation of the material during operation to ensure linear motion of the material. Optional left and right limit switches prevent the system from running out of control.

The rectifying device is mainly used for the lateral deviation control of the reel material, and can be used for various coil materials such as web film, metal foil, non-woven fabric, woven fabric, etc. on a long and fast production line, because of speed, Pulling force or uneven thickness of materials and various types of mechanical damage, causing the material to move left and right on the production line and unidirectional deviation, so that the processing action in the middle section is not easy to match, or the movement of the front and rear sections is not smooth, resulting in many materials. Loss and subsequent processing difficulties. The photoelectric-to-edge line-to-line device can solve this problem. The corrector is used for: coating machine, self-adhesive machine, laminating machine, slitting machine, rewinding machine, packaging and printing machinery, etc.

Attention problem

1. Precautions during installation

a. Pay great attention to avoid installation deviations during installation

(1) The upper pressing gland should be carried out after the coupling is aligned. The bolts should be evenly supported to prevent the end face of the gland from being skewed. Check the points with a feeler gauge. The error is not more than 0.05 mm.

(2) Check the fit clearance (ie, concentricity) between the gland and the outer diameter of the shaft or bushing. The circumference should be uniform. Check the tolerance of each point with a feeler gauge to be no more than 0.01 mm.

b. The amount of spring compression should be carried out according to the regulations. It is not allowed to be too large or too small, and the required error is 2.00 mm. Over the assembly, the end face is pressed and the other end face is worn. Too small will cause insufficient specific pressure and will not seal.

c. After the moving ring is installed, it can be flexibly moved on the shaft. After the moving ring is pressed against the spring, it should be able to spring back automatically.

2. Precautions when disassembling

2. Precautions when disassembling

a. Care should be taken when disassembling the mechanical seal. Do not use the hand hammer and the flat shovel to avoid damage to the sealing components. A pair of wire hooks can be made, and the sealing device is pulled out in the direction of self-supporting profit and loss into the gap of the transmission seat. If the scale is not removed, it should be cleaned before disassembly.

b. If mechanical seals are used on both ends of the pump, take care of each other during assembly and disassembly to prevent loss.

c. For the mechanical seal that has been operated, if the gland is loose to move the seal, the static and dynamic ring parts must be replaced and should not be re-tightened for continued use. Because after the turbulence, the original trajectory of the friction pair will change, and the sealing of the contact surface will be easily damaged.

Packing

Order Details

|

Item Name |

PG series Web Guide Control System |

|

MOQ(Minimum Order Quantity) |

1Pc |

|

Lead time |

10-15 days after receiving the deposit |

|

Calculated Weight |

depends on the model |

|

Package |

Carton/Wooden Box |

|

Price Term |

EXW,FOB, CIF, etc |

|

Payment term |

TT,L/C,Western Union |

|

Country of Origin |

China |

Hot Tags: web aligner manufacturer, China, manufacturers, suppliers, factory, quotation, pricelist, buy