Web Guiding Principles

The working principle of the web guide system: The coil rectification control system is a closed-loop controller, controller, sensor, and linear guide mechanism that form the basic part of the closed-loop control. First, the rectification sensor detects the edge or line of the coil, and the...

The working principle of the web guide system:

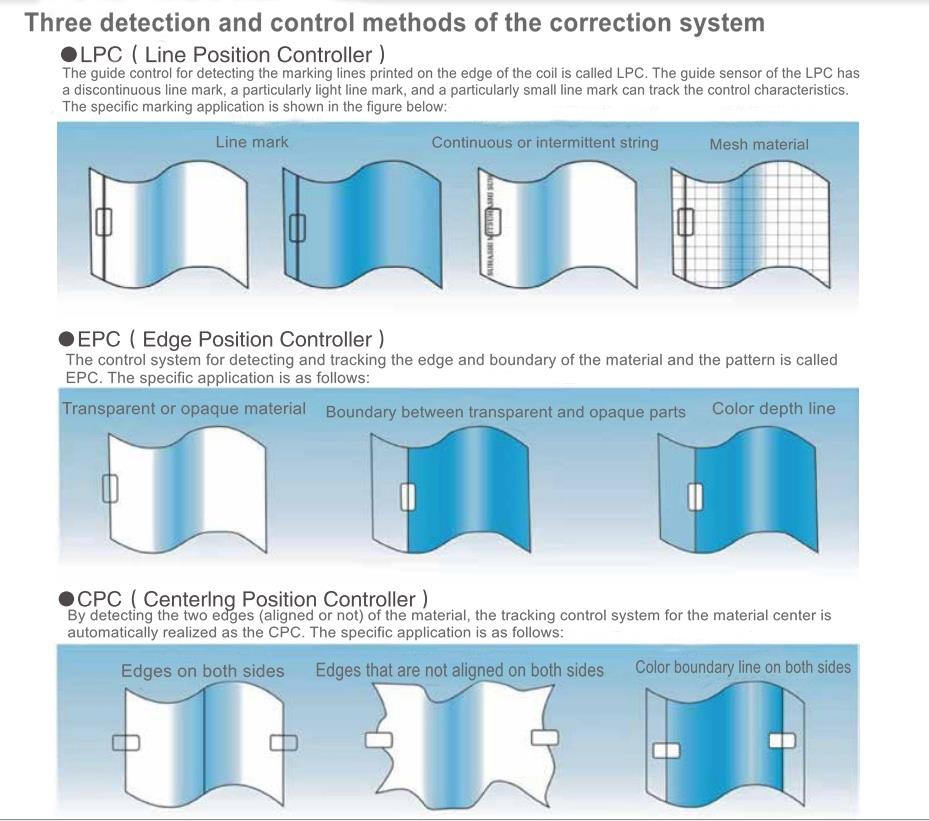

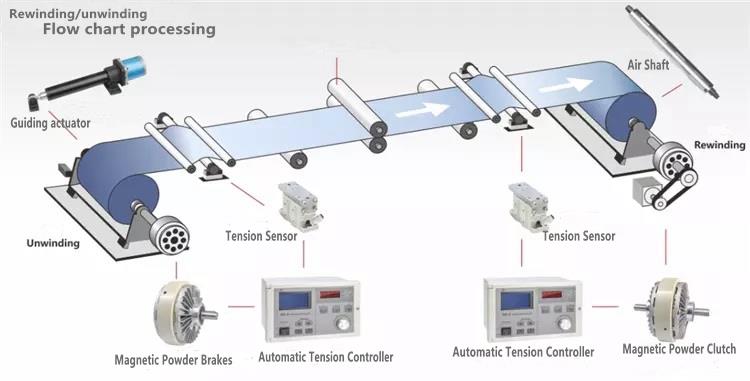

The coil rectification control system is a closed-loop controller, controller, sensor, and linear guide mechanism that form the basic part of the closed-loop control. First, the rectification sensor detects the edge or line of the coil, and the system automatically reads the actual position and design of the coil. The offset of the position is converted, and the offset is converted into a proportional electrical signal to the controller. The signal is amplified and calibrated by the controller, and then output to the linear driver. The linear driver drives the correcting and guiding according to the magnitude of the signal. The mechanism returns the coil to the set position. The drive signal of the current drive is only proportional to the amount of deflection of the coil, which allows precise control of the various coils and web guide systems.

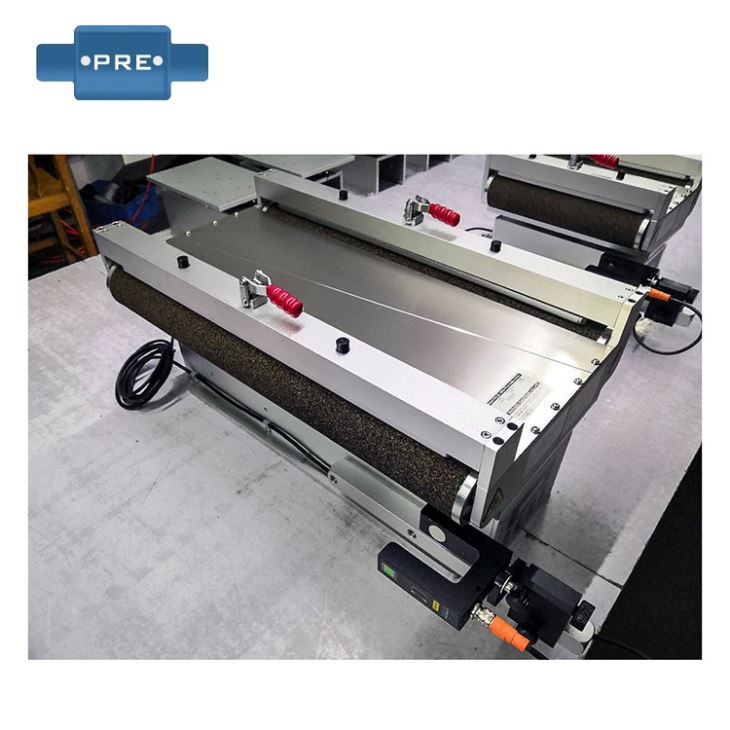

- Industrial control systems for steel, corrugated, textile, printing, labeling, labeling, paper, plastic film, building materials, cables, rubber, tires, etc. Guide control refers to the technical operation of the coil produced by the manufacturer during the spraying, printing, punching, laminating, slitting or other coil winding process, always keeping the sides of the coil neat and consistent. Because the edge of the coil is not aligned, it will cause subsequent step errors, resulting in material waste or downtime adjustment. Therefore, when processing the processed coil, it is necessary to perform a timely guiding operation on the offset coil, which is called rectification. The entire process of the device constitutes a set of correction systems. Web guide systems are extremely diverse and are essential in the packaging, printing, labeling, construction materials, pulp, household paper, plastics, garments, cables, metal processing, nonwovens, corrugated paper processing and other industries. A typical guide system includes a guide controller, a guide sensor, a guide frame, and a driver.

Operation and maintenance

Precautions

a. Thoroughly check the mechanical seal, and whether the attachments and pipelines are installed properly and meet the technical requirements.

b. Perform static pressure test before starting the mechanical seal to check whether the mechanical seal has leakage. If there are more leaks, you should find out the reasons and try to eliminate them. If it is still invalid, it should be disassembled and reinstalled. Generally, the static pressure test pressure is 2~3 kg/cm2.

c. Press the pump to turn the disc to check if it is light and even. If the car is struggling or not moving, check whether the assembly size is wrong and the installation is reasonable.

Installation and outage

a. Keep the sealed chamber filled with liquid before starting. For transporting the solidified medium, steam is applied to heat the sealed chamber to melt the medium. The car must be driven before starting to prevent the soft ring from breaking due to sudden start.

b. For the mechanical seal using the pump external sealing system, the oil sealing system should be activated first. Finally stop the oil sealing system after parking.

c. After the hot oil pump is stopped, the cooling water of the sealing oil chamber and the end face seal cannot be stopped immediately. When the oil temperature of the end seal is lowered to below 80 degrees, the cooling water can be stopped to avoid damage to the sealing parts.

Running

a. If there is a slight leakage after the pump starts, it should be observed for a while. If the leakage is still not reduced after 4 hours of continuous operation, the pump should be stopped.

b. The operating pressure of the pump should be stable and the pressure fluctuation should be no more than 1 kg/cm 2 .

c. During the operation of the pump, evacuation should be avoided to avoid dry friction and seal damage on the sealing surface.

d. Sealing should be checked frequently. During operation, when the leakage exceeds the standard, the heavy oil is not more than 5 drops/min, and the light oil is not more than 10/min. If there is no improvement trend within 2-3 days, the pump plug should be stopped to check the sealing device.

Packing

Order Details

Item Name | PG series Web Guide Control System |

MOQ(Minimum Order Quantity) | 1Pc |

Lead time | 10-15 days after receiving the deposit |

Calculated Weight | depends on the model |

Package | Carton/Wooden Box |

Price Term | EXW,FOB, CIF, etc |

Payment term | TT,L/C,Western Union |

Country of Origin | China |

Hot Tags: web guiding principles, China, manufacturers, suppliers, factory, quotation, pricelist, buy