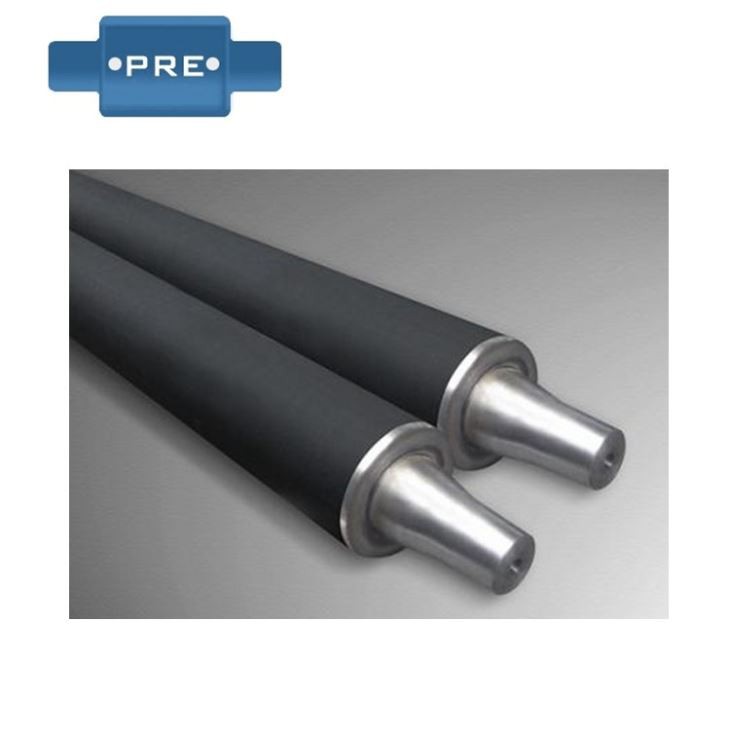

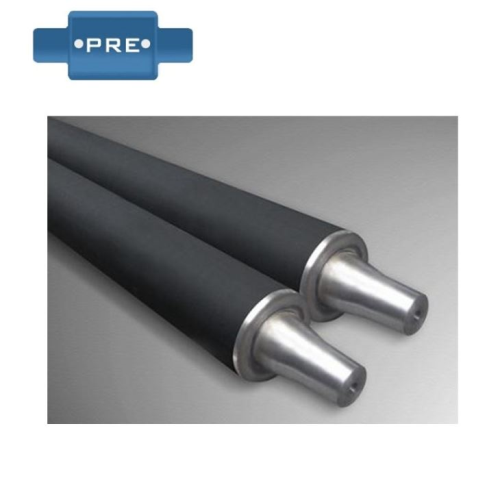

Carbon Fiber Rollers

Carbon Fiber Rollers Low-Inertia, low-drag idler rollers (composite rollers). Respond immediately to changes in web speed. Less vibration at higher speeds. Line speed achieved almost immediately. Large diameter carbon fiber roller Carbon fiber idler rollers (composite rollers) are designed for...

Carbon Fiber Rollers

Low-Inertia, low-drag idler rollers (composite rollers).

Respond immediately to changes in web speed.

Less vibration at higher speeds.

Line speed achieved almost immediately.

Large diameter carbon fiber roller

Carbon fiber idler rollers (composite rollers) are designed for reduced weight and high critical speed.

Lightweight, low-inertia idler rollers allow faster web speeds, reduce vibration, decrease waste, and improve product quality.

light weight, higher critical speed, reduced vibration, less deflection, and faster line speeds.

With carbon fiber rollers in place, machines can run at faster speeds and the web is far less likely to drag and get damaged. These improvements in shaft and roller performance directly affect productivity and increase machine throughput.

FEATURE

1, Low Rotational Inertia

(Reduced mass moment of inertia by up to 80%)

2, High Stiffness

(High Modulus)

3, High Specific Modulus

(High Stiffness to Density Ratio)

4, Low Mass

5, Low Momentum

Carbon fiber is a kind of fibrous carbon material with higher strength than steel, lower density than aluminum, better corrosion resistance than stainless steel, high temperature resistance than heat resistant steel, and a new material that can conduct electricity and conduct heat like copper. Composite material made of carbon fiber and resin is light and consumes less power.

Material: | carbon fifber |

Diameter: | 50 mm-250 mm |

Length: | 100-6000 mm |

Balancing: | Dynamic balance |

ADVANTAGE

1, Rollers spin at line speed. Serrations are not used so dust is not created.

2, Quicker response to changes in line speed.

3, Less horsepower and/or fewer motors required.

4, Less deflection

5, Faster line speeds with less vibration (higher critical speed).

6, Less self-loaded deflection.

7, Super lightweight.

8, Less bearing wear.

9, More accurate transducer measurements.

10, Less lay-on roller bounce.

11, Quicker dancer and accumulator roller response.

The application form of carbon fiber composite materials in the industrial field is gradually diversified, and the carbon fiber composite material roll is one of the most promising application forms. Recently, carbon fiber rolls have been gradually used in various industrial machines, such as papermaking machinery, printing machinery, textile machinery, film machinery, etc. In general, the application advantages of carbon fiber rolls are very prominent, compared with the traditional metal rolls. Light weight, low inertia, low deflection angle and high natural frequency. This article gives a brief introduction to the carbon fiber roller for industrial machinery for the case of the domestic carbon fiber professional manufacturer Wuxi Zhishang New Material Technology Co., Ltd.

Raising roller for textile machinery:

A pilling machine is a textile machine that pulls the ends of the fibers out of the yarn to evenly coat the surface of the fabric with a pile of fluff. The raising roller is the most important roller body on the raising machine. The traditional raising roller is made of steel. In order to meet the high speed requirements of the raising machine, the steel raising roller must have sufficient wall thickness to ensure sufficient rigidity, but this rigidity It is at the cost of increasing its own weight and increasing energy consumption. Even so, the fatigue resistance of the steel raising roller is still not satisfactory, because the metal texture has a certain ductility. During the high-speed operation, the longer the steel roller, the more easily the distortion occurs, which affects the quality of the raising. effect. Therefore, such steel raising rolls are also limited in length, and generally do not exceed two meters to avoid significant deformation.

Packing

Order Details

Item Name | Carbon Fiber Rollers |

MOQ(Minimum Order Quantity) | 1PC |

Lead time | 10-15 days after receiving the deposit |

Calculated Weight | Need to count |

Package | Wooden Box/Pallet packing/according to clients’demand |

Price Term | EXW,FOB, CIF, etc |

| Payment term | TT,L/C,Western Union |

| Country of Origin | China |

Hot Tags: carbon fiber rollers, China, manufacturers, suppliers, factory, quotation, pricelist, buy