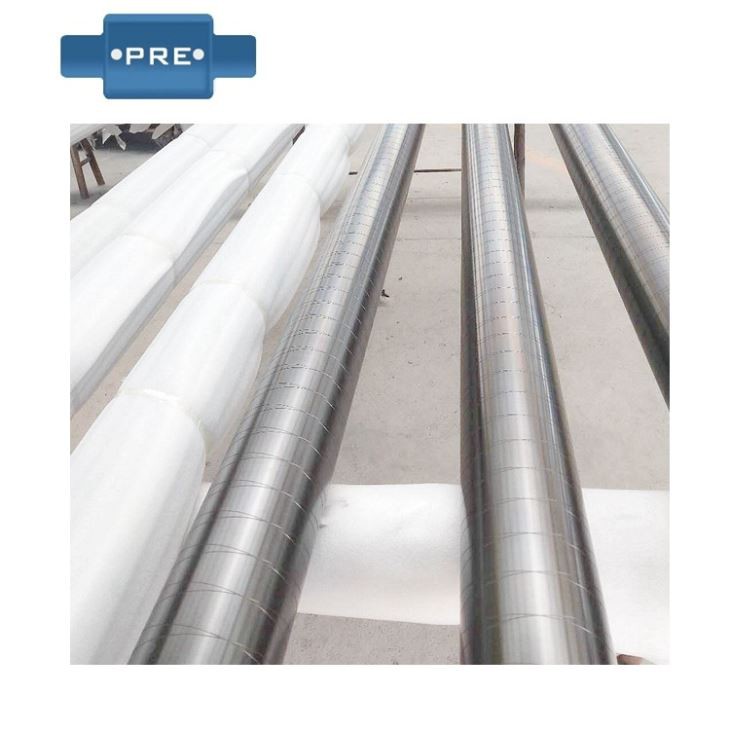

Aluminum Groove Roller

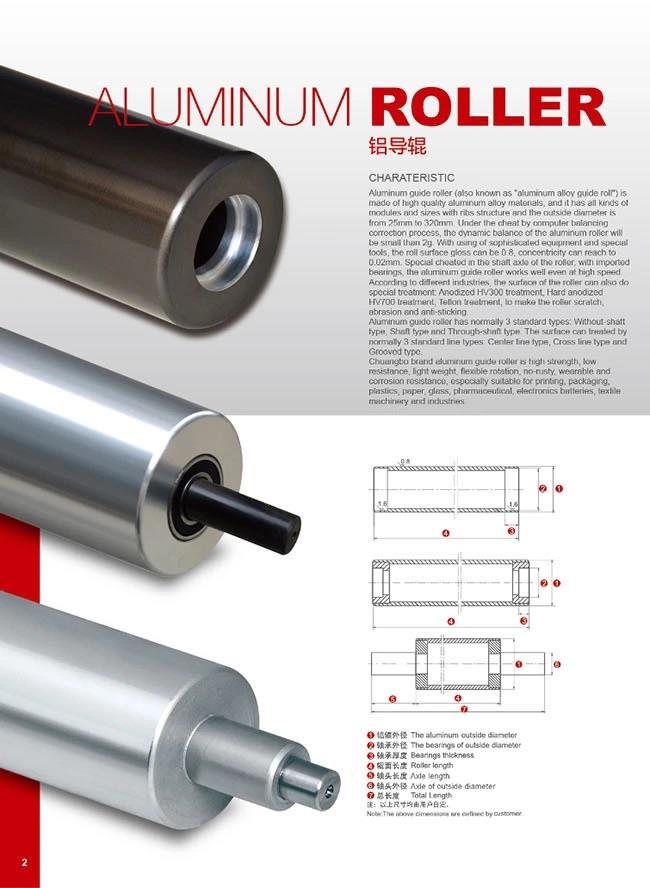

Aluminum tube is also called aluminum roller, it is made of advantaged aluminum alloy material. It has all kinds of modules and sizes. Inside the roller, there is a strong rib structure, chich is very fixed. And the Omni-axes is controlled by dynamic balance correction treatment, which limits to...

Aluminum tube is also called aluminum roller, it is made of advantaged aluminum alloy material. It has all kinds of modules and sizes. Inside the roller, there is a strong rib structure, chich is very fixed. And the Omni-axes is controlled by dynamic balance correction treatment, which limits to 2g. with the special cutting method, the roll surface's lustrousness is from 1.6 to 0.8, and coaxially is 0.02mm. the axle end under technology processing and with best bearing, though it is running with high speed, it still works well. according to different industry, the roller can also be used in anodic oxidation HV300, HV700, Teflo, it can bear the stuff working surrounding.

O.D(mm) | I.D(mm) | Wall Thickness | Stiffener |

Ф32 Ф33 Ф40 | Ф24 Ф27 Ф34 | 4:00 3:00 3.00 |

8 |

Ф40.5 Ф42.5 serrated roller Ф43.8 | Ф31 Ф30 Ф34.5 | 5.00 4.50 5.00 | |

Ф47 Ф50.5 Ф51 with groove | Ф40.8 Ф40.5 Ф38 | 3.00 5.00 6.50 | 8

6 |

Ф55 Ф58.5 Ф61 | Ф46.5 Ф51.5 Ф51 | 4.50 3.50 4.90 | 6 8 6 |

Ф70 serrated roller Ф71 Ф71 | Ф46 Ф63.2 Ф61 | 7.20 4.50 3.50 |

8 7 |

Ф74.5 Ф75.5 Ф80 | Ф60 Ф66 Ф73 | 7.20 4.50 3.50 |

8 8 |

Ф81 Ф81 Ф80 | Ф72.5 Ф71 Ф69 | 4.30 5.00 5.50 | 8 8 8 |

Ф90 Ф99 Ф101 | Ф81 Ф90.5 Ф92 | 4.50 4.30 4.50 | 8 8 7 |

Ф101.5 Ф101 Ф101 | Ф91.5 Ф89 Ф86.3 | 4.50 11.00 11.00 | 7 8 8 |

Ф111 Ф115 Ф116 | Ф102 Ф93 Ф94 | 4.50 11.00 11.00 |

7 8 |

Ф120.5 Ф121.5 Ф130.5 | Ф105.5 Ф111.5 Ф118 | 7.50 5.00 6.25 |

9 |

Ф140 Ф145 Ф151.5 | Ф120 Ф123 Ф139.5 | 10.00 11.00 6.20 | 8 7 8 |

Ф151.5 Ф153 Ф162 | Ф131.5 Ф121 Ф148 | 10.00 11.00 7.00 |

9 |

Ф184 Ф203 | Ф168 Ф179 | 8.00 12.00 | |

Ф150.5 Ф151 Ф200 Ф320 | Ф136.5 Ф140 Ф186 Ф296 | 7.00 5.50 7.00 12.00 |

10 |

The roller of the aluminum guide roller serves to support the conveyor belt and the weight of the material. The roller must be flexible and reliable. Reducing the friction between the conveyor belt and the idler roller plays a key role in the life of the conveyor belt, which accounts for more than 25% of the total cost of the conveyor.

The criteria for judging the quality of the rollers are as follows: the amount of radial runout of the idler; the flexibility of the idler; the amount of axial turbulence.

The roller of the aluminum guide roller is an important part of the belt conveyor, and has many types and a large number.

It accounts for 35% of the total cost of a belt conveyor and withstands more than 70% of the resistance, so the quality of the rollers is particularly important.

Although the rollers of the aluminum guide rolls are a small part in the belt conveyor and the structure is not complicated, it is not easy to manufacture a high quality idler.

In order to improve the wear resistance and crack resistance of the rolling mill guide rolls, plasma cladding technology is adopted.

After testing, the coating obtained by the above plasma cladding process is uniform and dense, and has no pores and no cracks. Since the 45 steel substrate has good thermal conductivity and solidification speed is fast when cooled in air, the structure of the obtained coating and the precipitated phase therein are very fine and uniform.

Compared with conventional high-chromium cast steel guide rolls, the plasma alloy guide rolls have a significantly improved service life. The service life of high-chromium cast steel guide rolls is generally 8 hours. After that, serious wear grooves and fatigue cracks appear. The deep grooves generated by wear will cause sticking steel and calendering, which will seriously affect the surface quality of the steel. Retirement expired. The plasma alloy guide roller has remarkable resistance to abrasive wear and thermal fatigue resistance, and its average service life reaches 138 hours. Moreover, after repairing the guide roller, the average life span can reach 96 hours, and the effect is very remarkable.

Through the comprehensive evaluation of the plasma alloy guide rolls, it can be known that the application of the plasma cladding technology on the guide rolls of the rolling mill can significantly improve the service life of the rolling mill guide rolls, thereby reducing the cost of guide roller handling and loading, and reducing the labor intensity and guidance of frequent replacement. The waste of steel rolling work time caused by the disassembly and handling of the roller can increase the amount of steel rolling, save a large amount of high-quality steel, and also reduce the safety accident caused by the damage of the guide roller.

Question:

Can you customized the rolls for me if I provide the size or drawing?

Answer:

Yes! All the rolls and shafts are customized for every customer.

Question:

I need the roll which diameter not included in your list, can you produce?

Answer:

Yes! We can produce all sizes of rolls.

Question:

What is the minimum order of the rolls?

Answer:

The minimum order is only 1 piece.

Question:

What is the delivery time of the roll?

Answer:

According to the quantity you order, mostly is within 30 working days.

Aplication

Packing

Order Details

Item Name | Aluminum groove roller |

MOQ(Minimum Order Quantity) | 1PC |

Lead time | 10-15 days after receiving the deposit |

Calculated Weight | Need to count |

Package | Wooden Box/Pallet packing/according to clients’demand |

Price Term | EXW,FOB, CIF, etc |

| Payment term | TT,L/C,Western Union |

| Country of Origin | China |

Hot Tags: aluminum groove roller, China, manufacturers, suppliers, factory, quotation, pricelist, buy