24V Magnetic Powder Brake

The magnetic powder brake is based on the electromagnetic principle and uses magnetic powder to transmit torque. It has the characteristics that the excitation current and the transmission torque are basically linear. It can transmit a certain torque regardless of the slip, and has the...

The magnetic powder brake is based on the electromagnetic principle and uses magnetic powder to transmit torque. It has the characteristics that the excitation current and the transmission torque are basically linear. It can transmit a certain torque regardless of the slip, and has the advantages of fast response, simple structure, no pollution, no noise, no impact vibration and energy saving.

The preparations and precautions before starting the magnetic powder brake are as follows:

1. Inspection before installation

a. Thoroughly check the mechanical seal, and whether the attachments and pipelines are installed properly and meet the technical requirements.

b. Perform static pressure test before starting the mechanical seal to check whether the mechanical seal has leakage. If there are more leaks, you should find out the reasons and try to eliminate them. If it is still invalid, it should be disassembled and reinstalled. Generally, the static pressure test pressure is 2~3 kg/cm2.

c. Press the pump to turn the disc to check if it is light and even. If the car is struggling or not moving, check whether the assembly size is wrong and the installation is reasonable.

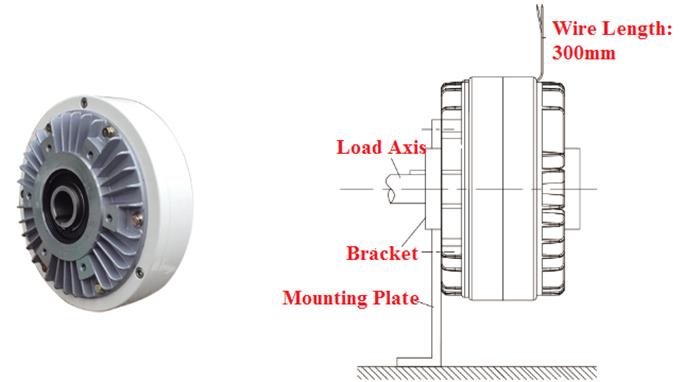

2, installation and outage

a. The magnetic powder clutch should be filled with liquid in the sealed chamber before starting. For transporting the solidified medium, steam is applied to heat the sealed chamber to melt the medium. The magnetic powder brake must be driven before starting to prevent the soft ring from breaking due to sudden start.

b. For the mechanical seal using the pump external sealing system, the oil sealing system should be activated first. Finally stop the oil sealing system after parking.

c. After the hot oil pump is stopped, the cooling water of the sealing oil chamber and the end face seal cannot be stopped immediately. When the oil temperature of the end seal is lowered to below 80 degrees, the cooling water can be stopped to avoid damage to the sealing parts.

3, running

a. If there is a slight leakage after the pump starts, it should be observed for a while. If the leakage is still not reduced after 4 hours of continuous operation, the pump should be stopped.

b. The operating pressure of the pump should be stable and the pressure fluctuation should be no more than 1 kg/cm 2 .

c. During the operation of the pump, evacuation should be avoided to avoid dry friction and seal damage on the sealing surface.

d. Sealing should be checked frequently. During operation, when the leakage exceeds the standard, the heavy oil is not more than 5 drops/min, and the light oil is not more than 10/min. If there is no improvement trend within 2-3 days, the pump plug should be stopped to check the sealing device.

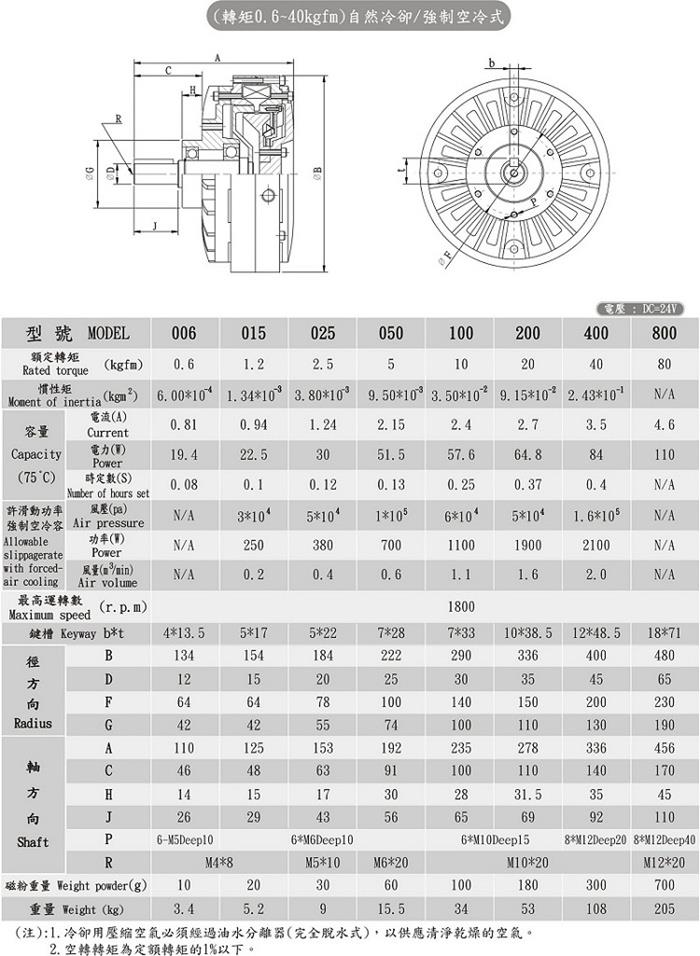

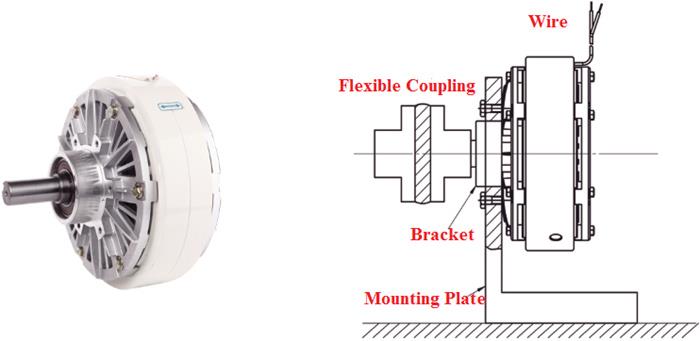

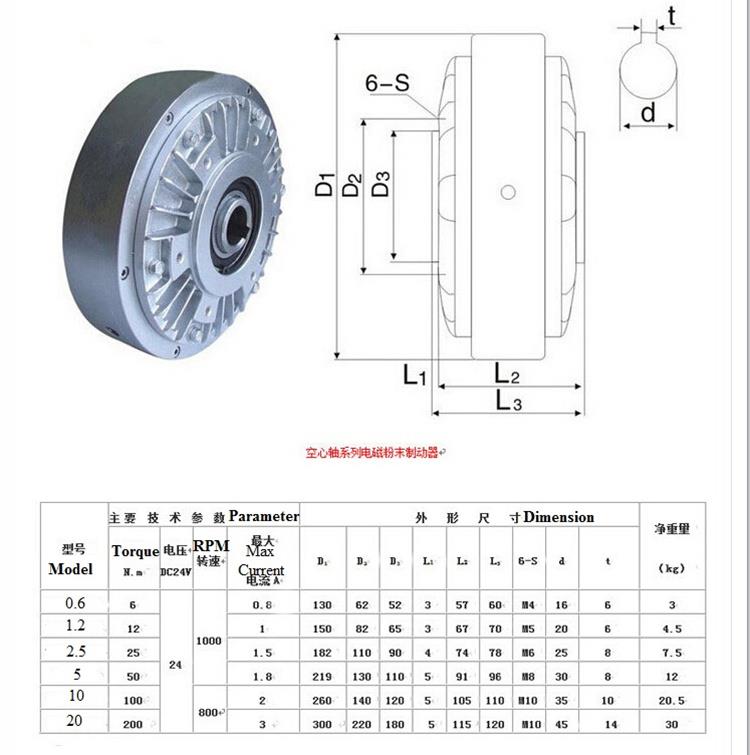

PRE-B Single Shaft Magnetic Powder Brake

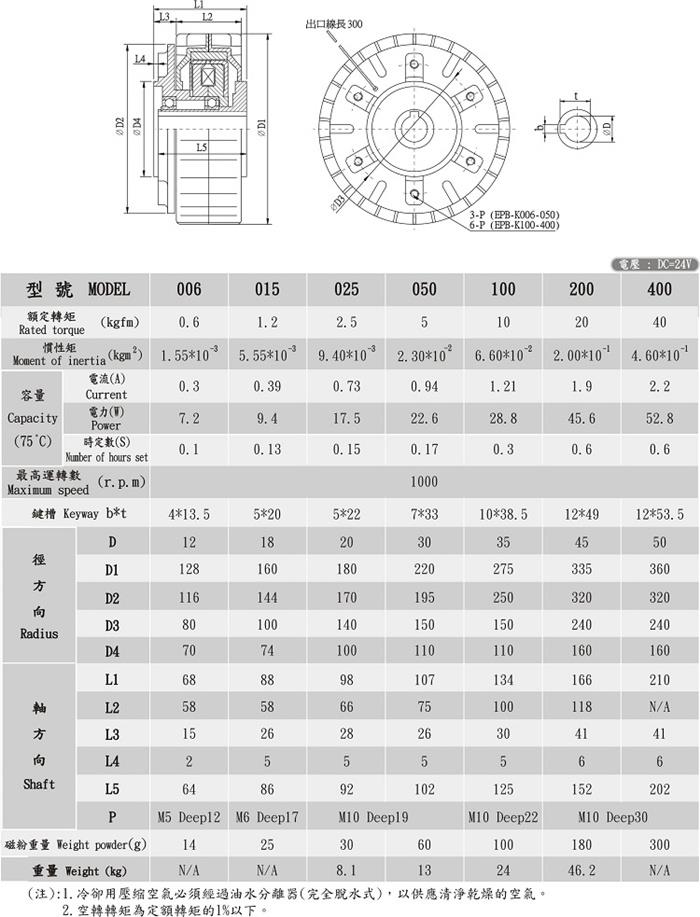

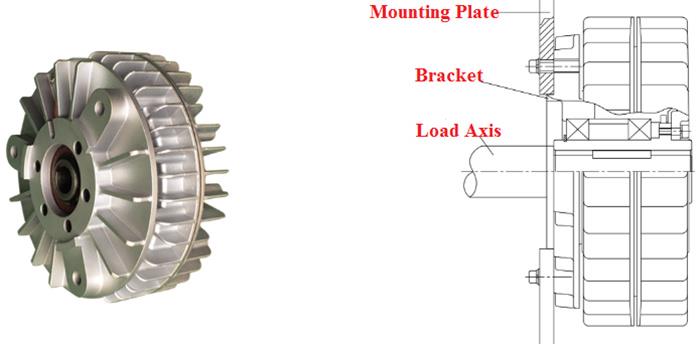

PRE-B1 Hollow Shaft Shell Rotating Magnetic Powder Brake

PRE-B2 Hollow Shaft Inner Shell Rotating Magnetic Powder Brake

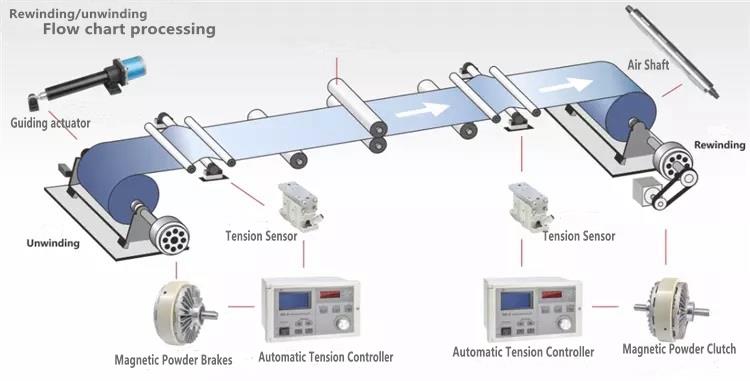

The magnetic powder brake and magnetic powder clutch are an excellent automatic control component. It uses magnetic powder as the working medium and uses the excitation current as the control means to achieve the purpose of controlling braking torque or transmitting torque. The output torque has a good linear relationship with the excitation current, and has nothing to do with the speed or slip, and has the advantages of fast response speed and simple structure.

See the following points for details:

1. Excitation current——torque characteristic: The excitation current has a good linear relationship with the torque. The excitation current can be used to control the torque infinitely.

2. Speed - Torque characteristics: The torque is independent of the speed and maintains a fixed value. There is no difference between static torque and dynamic torque. Its characteristics are shown in Figure B.

3. Load characteristics: The allowable slip power of the magnetic powder brake is a fixed value when the heat dissipation condition is constant. When it is continuously running, the actual slip needs to be within the allowable slip power. When using the high speed, reduce the torque.

Magnetic powder brakes are widely used. The practical applications include large-scale transmission equipment, walking cranes, large blowers, axial fans, air compressors, cement kilns, paper machines, rotary impact machines, rolling, rolling machines, wire drawing machines, Large-scale textile, printing and dyeing, printing machinery, and the inching and operation of various industrial machinery.

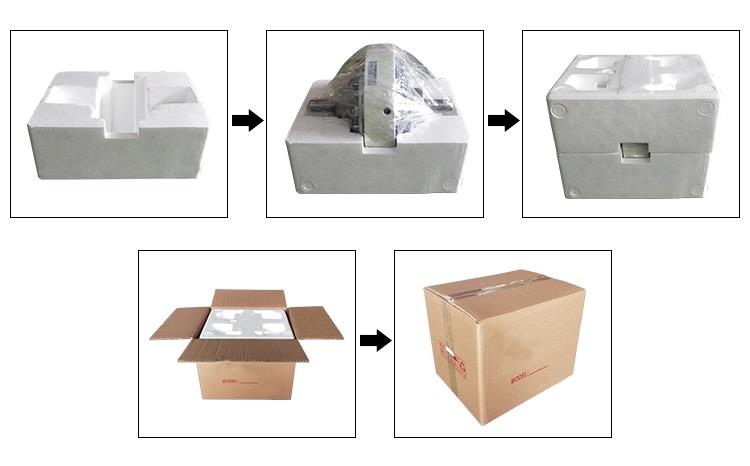

Packing

Order Details

Item Name | Magnetic Powder Brake |

MOQ(Minimum Order Quantity) | 1Pc |

Lead time | 3-5 days after receiving the deposit |

Calculated Weight | According to different models |

Package | Carton/Wooden Box |

Price Term | EXW,FOB, CIF, etc |

Payment term | TT,L/C,Western Union |

Country of Origin | China |

Hot Tags: 24v magnetic powder brake, China, manufacturers, suppliers, factory, quotation, pricelist, buy