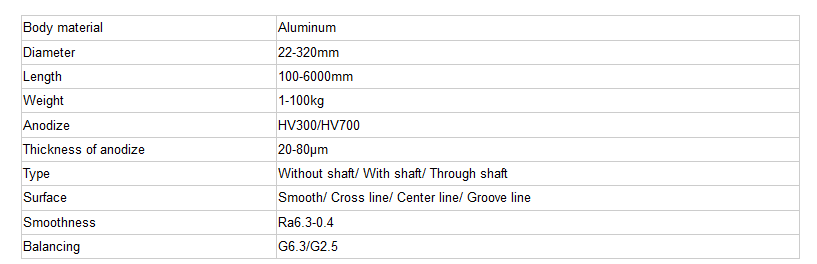

Aluminum Idler Rollers

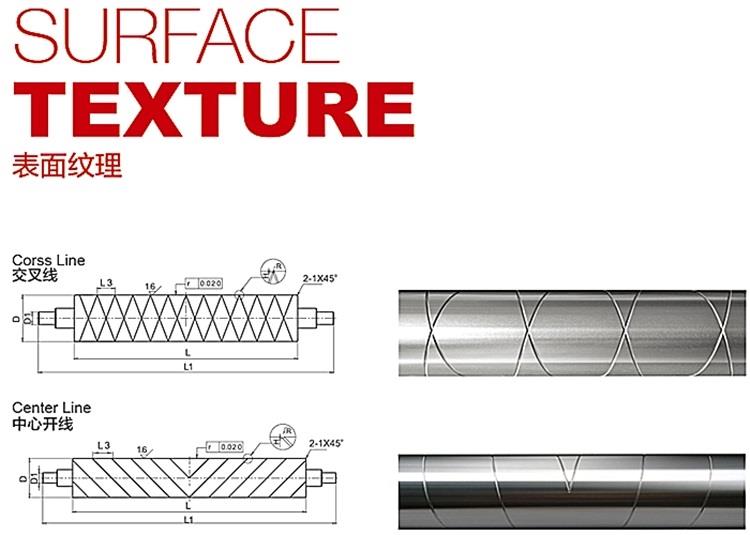

The aluminum guide boring machine uses precise equipment and special tools for surface finishing, which makes the surface smooth, the coaxiality reaches 0.02mm, the whole axis is corrected by the computer balance correction within 2g, the special technology of the shaft end and the imported...

The aluminum guide boring machine uses precise equipment and special tools for surface finishing, which makes the surface smooth, the coaxiality reaches 0.02mm, the whole axis is corrected by the computer balance correction within 2g, the special technology of the shaft end and the imported bearings, under high speed operation, All can work easily and freely.

The aluminum guide is made of high-quality aluminum alloy. It has nine reinforcing ribs and a wall thickness of 5cm. The surface treatment is based on user requirements. It has ordinary oxidation, hard oxidation, Teflon, etc. to ensure its rigidity and wear resistance. Sex.

Using Taiwan's imported precision processing equipment, tools and measuring tools, the surface roughness of the manufactured roller is 0.8, the coaxiality is 0.02mm, and the reasonable shaft connection method can easily run freely at any running speed, never transform.

The aluminum guide has high strength, low resistance, corrosion resistance, light weight, smooth rotation and no rust.

O.D(mm) | I.D(mm) | Wall Thickness | Stiffener |

Ф32 Ф33 Ф40 | Ф24 Ф27 Ф34 | 4:00 3:00 3.00 |

8 |

Ф40.5 Ф42.5 serrated roller Ф43.8 | Ф31 Ф30 Ф34.5 | 5.00 4.50 5.00 | |

Ф47 Ф50.5 Ф51 with groove | Ф40.8 Ф40.5 Ф38 | 3.00 5.00 6.50 | 8

6 |

Ф55 Ф58.5 Ф61 | Ф46.5 Ф51.5 Ф51 | 4.50 3.50 4.90 | 6 8 6 |

Ф70 serrated roller Ф71 Ф71 | Ф46 Ф63.2 Ф61 | 7.20 4.50 3.50 |

8 7 |

Ф74.5 Ф75.5 Ф80 | Ф60 Ф66 Ф73 | 7.20 4.50 3.50 |

8 8 |

Ф81 Ф81 Ф80 | Ф72.5 Ф71 Ф69 | 4.30 5.00 5.50 | 8 8 8 |

Ф90 Ф99 Ф101 | Ф81 Ф90.5 Ф92 | 4.50 4.30 4.50 | 8 8 7 |

Ф101.5 Ф101 Ф101 | Ф91.5 Ф89 Ф86.3 | 4.50 11.00 11.00 | 7 8 8 |

Ф111 Ф115 Ф116 | Ф102 Ф93 Ф94 | 4.50 11.00 11.00 |

7 8 |

Ф120.5 Ф121.5 Ф130.5 | Ф105.5 Ф111.5 Ф118 | 7.50 5.00 6.25 |

9 |

Ф140 Ф145 Ф151.5 | Ф120 Ф123 Ф139.5 | 10.00 11.00 6.20 | 8 7 8 |

Ф151.5 Ф153 Ф162 | Ф131.5 Ф121 Ф148 | 10.00 11.00 7.00 |

9 |

Ф184 Ф203 | Ф168 Ф179 | 8.00 12.00 | |

Ф150.5 Ф151 Ф200 Ф320 | Ф136.5 Ф140 Ф186 Ф296 | 7.00 5.50 7.00 12.00 |

10 |

Aluminium guide roller multi-purpose broken pores and skin feather cloth roll guide fabric curler and guide missile fabric guide curler meeting cowl about the right end has a guide curler steam to form a hole tube assumed in the cover meeting and the steam passage, hole short shaft guide fabric the curler adheres to the steam engine and the duration of the inner and outer ring of the agency and the length of the guide curler of the manual curler nearly enters the hole tube shaft and the short shaft. the pipe is fixedly related with the steam cover. the pipe is issued and the gasoline is handed via the manual curler. the steam roller assumes that i take advantage of the axial groove b of the nozzle and the guide cloth manual curler meeting.

The left and proper bulkheads are tumbling from the inlet hole shaft and the quick shaft of the bearing and the steam guide roller assembly. the guide curler is a guide curler assembly having a hollow guide curler and left and proper bulkheads disposed at both ends of the hollow manual curler, and similarly having a steam guide roller meeting; the steam manual fabric the roller meeting is composed of a steam storage guide roller with a left and right quit cowl, an inlet hole tube shaft and a short shaft; the steam garage manual curler is disposed inside the hollow manual roller; the inlet hole tube shaft and the quick axis is fixedly coupled with the left and proper cease caps of the steam garage guide curler; the inner hollow of the inlet hollow tube shaft penetrates with the inner cavity of the steam garage manual curler; the steam garage guide curler is narrowly disposed along the axial direction the nozzle of the manual curler assembly is a mesh guide roller, and the left and right heads are specifically connected by way of the bearing and the inlet hole tube shaft and the fast shaft.

The manual curler has more than one features including heating, de-mixing and dehydration. the application version can simplify the mechanical structure, keep strength intake and do away with the impurities at the floor of the fabric to improve the pleasant of the cloth of the finished product.

A multi-reason guide curler having an aluminum guide roller meeting that is externally closed by means of a hole guide curler and an internal cavity formed via left and proper bulkheads disposed at both ends of the hollow manual roller.

Application

Order Details

Item Name | Aluminum roller |

MOQ(Minimum Order Quantity) | 1PC |

Lead time | 10-15 days after receiving the deposit |

Calculated Weight | Need to count |

Package | Wooden Box/Pallet packing/according to clients's requirement and demand |

Price Term | EXW,FOB, CIF, etc |

| Payment term | TT,L/C,Western Union |

| Country of Origin | China |

Hot Tags: aluminum idler rollers, China, manufacturers, suppliers, factory, quotation, pricelist, buy