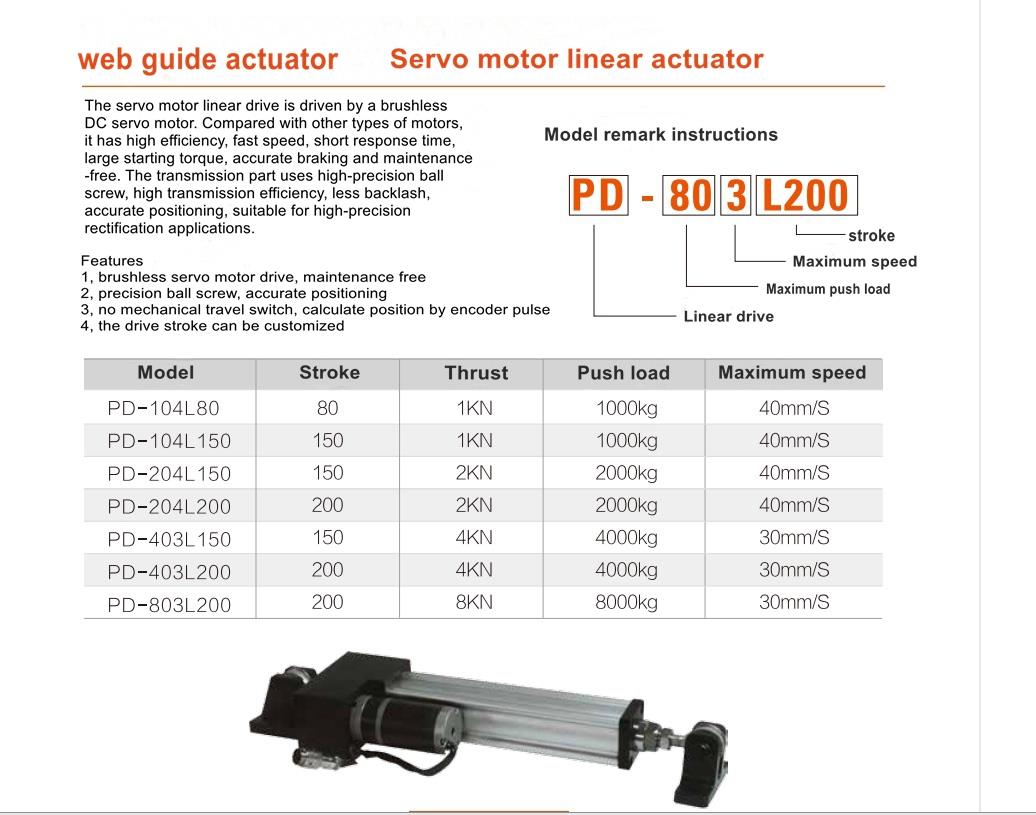

Web Guide System Electric Actuator

In the production process of printing, printing and dyeing, film, textile, packaging and other industries, thin materials are unwinded, transported and wound up on long high-speed production lines. Due to various mechanical reasons, the coils will be deflected, resulting in Problems such as...

In the production process of printing, printing and dyeing, film, textile, packaging and other industries, thin materials are unwinded, transported and wound up on long high-speed production lines. Due to various mechanical reasons, the coils will be deflected, resulting in Problems such as unwinding, unwinding, and intermediate transmission misalignment affect product quality and even fail to complete the production process.

The automatic guiding solves the above problem. If the coil is transferred, processed, unwinded or wound in the production line, if the deviation is made, the automatic guiding opportunity will automatically pull the material (tow) to the correct position in real time, so that the production process can be carried out smoothly and the product quality can be guaranteed. Automatic corrector is an indispensable production equipment for printing, printing and dyeing, film, textile, packaging and other industries.

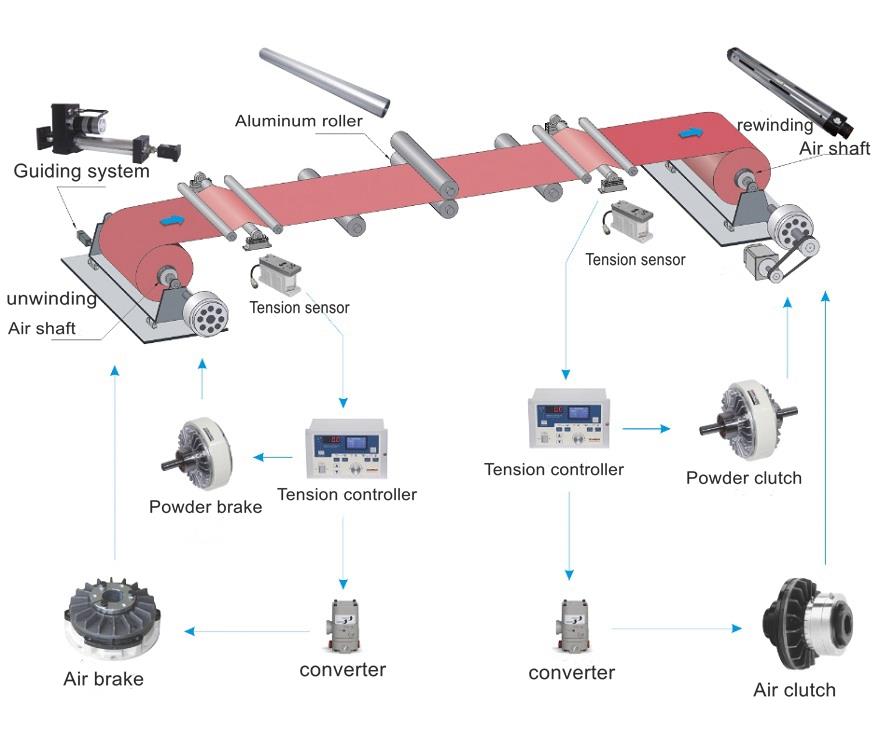

The automatic guiding is an electronic and mechanical integrated product, an internationally renowned brand, produced in Italy. It consists of three components: (1) detector, (2) amplifier, and (3) driver. The three components are connected by a dedicated cable.

Unwinding automatic tension correction control system (photoelectric edge-to-edge system): The tension of the unwinding is controlled by the braking torque of the magnetic powder brake in the unwinding device, and must be continuously reduced as the winding diameter of the winding is continuously reduced Braking torque. The tension detector is used to detect the tension of the winding, and the tension controller automatically controls the torque of the magnetic powder brake to make the tension constant.

Winding automatic tension correction control system (photoelectric edge-to-edge system): The winding speed is normally faster than the material's line speed, so the magnetic powder clutch works in the slip state, the tension is controlled by the torque of the magnetic powder clutch, in order to keep the tension constant. , must increase or decrease the torque of the magnetic powder clutch according to the size of the winding diameter

Rewinding and unwinding is a very important process in wire and cable, textile, metal processing, papermaking and other processing. At present, there are many ways to control the tension of the rewinding and unwinding in the winding system. The quality of the fully automatic tension correction control system (optical edge-to-edge system) directly affects the quality of the product. Due to the diversity and complexity of tension control, it is important to select a fully automatic tension correction control system (photoelectric edge-to-edge system) with reasonable design, reliable performance, convenient maintenance and economical rationality.

Packing:

Order Details

Item Name | Web Guide Actuator |

MOQ(Minimum Order Quantity) | 1Set |

Lead time | 2-3 days after receiving the deposit |

Calculated Packing Size | According to model |

Package | Carton/Wooden Box |

Price Term | EXW,FOB, CIF, etc |

Payment term | TT, L/C,Western Union |

Country of Origin | China |

Hot Tags: web guide system electric actuator, China, manufacturers, suppliers, factory, quotation, pricelist, buy