Particle Clutches

The magnetic powder clutch is separated by a transmission unit (input shaft) and a driven unit (input shaft). The space between the two groups of cells is filled with granular magnetic powder (remaining about 0.4 micron). When the magnetic coil is not conductive, the torque will not be...

The magnetic powder clutch is separated by a transmission unit (input shaft) and a driven unit (input shaft). The space between the two groups of cells is filled with granular magnetic powder (remaining about 0.4 micron). When the magnetic coil is not conductive, the torque will not be transmitted from the transmission shaft to the driven shaft. However, if the coil is electromagnetically energized, the magnetic powder will be released due to the magnetic dyeing, and the image will be straightened and smoothed. Torque communication.

The magnetic powder brake is an excellent automatic control component. It uses magnetic powder as the working medium and uses the excitation current as the control material to reach the purpose of controlling braking or transferring. The input transition and the excitation current are in a subtle linear relationship and are independent of the speed or slip, and have the advantages of fast response structure and redundant structure. Widely monopolized in the automatic control of tension, such as wire, cable, packaging, printing, paper and paper processing, textile, rubber and leather, metal foil strip processing, etc. The magnetic powder clutch is also used for buffer starting, overload screening, speed regulation, and the like.

(1) High precision torque control

The torque control scale is wide-ranging, and the control accuracy is high, and the torque and the exciting current are correctly proportional, and high-precision control can be realized.

(2) Superior durability and long life

It accepts super-alloy magnetic powder with high heat resistance, wear resistance, oxidation resistance and corrosion resistance, and has a long service life.

(3) The strong torque personality of the superiority

The magnetic particle has a good personality, and the powder particles are peaceful and peaceful, and the sliding torque is too strong. It is not related to the relative number of revolutions and can always throw a constant torque.

(4) Intermittent sliding operation monopoly

The cooling performance is exquisite and accepts the cooling layout with a thermal deformation of 1 and the high heat resistance of the magnetic powder. It is guaranteed to maintain a large braking power and sliding power, and the rough and smooth sliding operation will not cause the touch.

(5) Maintain a smooth, non-impact

The impact during maintenance is extremely small, and the rough and smooth impact is initiated and carried out. Moreover, the resistance torque is extremely small, and the magnetic powder brake does not cause useless fever.

(6) Stable high frequency operation

Respond to agile speed and special heat dissipation layout, stable high-frequency operation monopoly.

(7) Lightweight, no nursed back to health, long life

The type is cumbersome and lightweight, monopolizing the low-temperature resistant coils and special grease bearings, and applying special wear-resisting treatments to the armatures that are prone to wear and tear, shrinking the monopoly life.

The magnetic powder clutch is arranged with magnetic powder between the active and the driven parts. When the magnetic powder is not energized, the magnetic powder is in a meta-state. When the magnetic powder is energized, the magnetic powder is gathered, and the active part and the driven part are simultaneously turned. Sweet head: The conditioning current can be used to adjust the torque, and the larger slip can be allowed. Deviation: When the slip is large, the temperature rises greatly, and the absolute price is high.

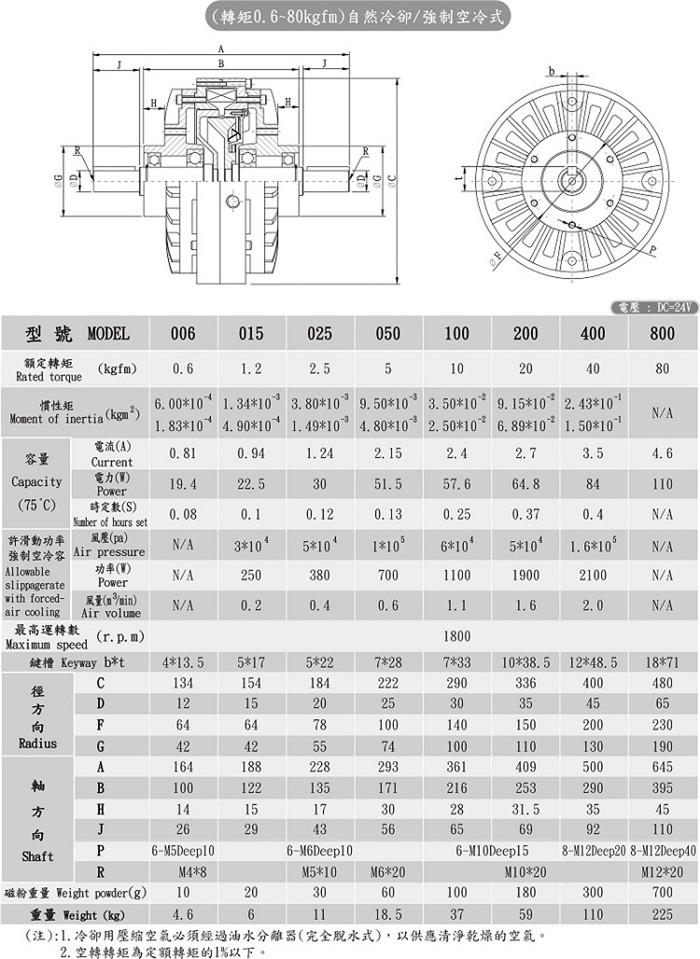

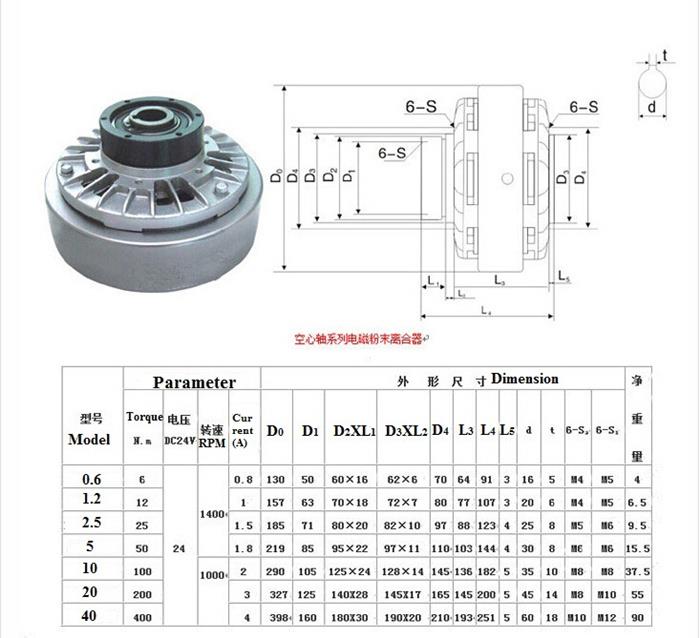

PRE-A Double Shaft Magnetic Powder Clutch

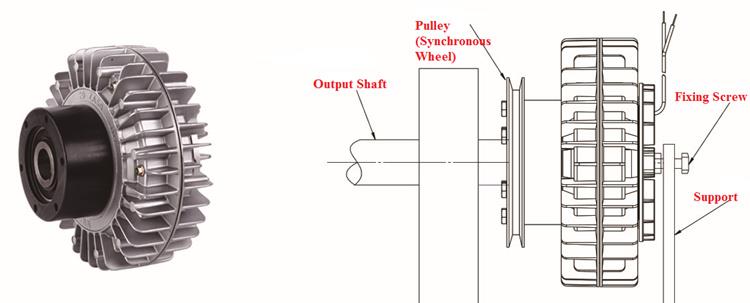

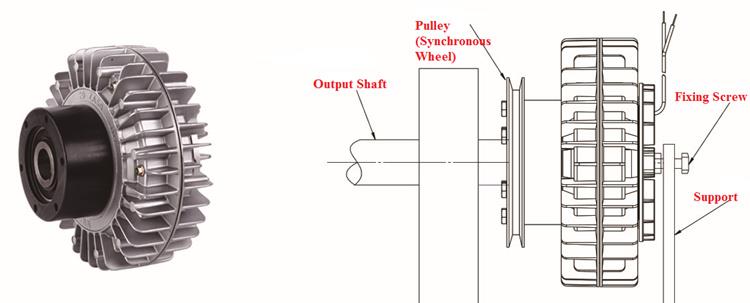

PRE-A1 Hollow Shaft Shell Rotating Magnetic Powder Clutch

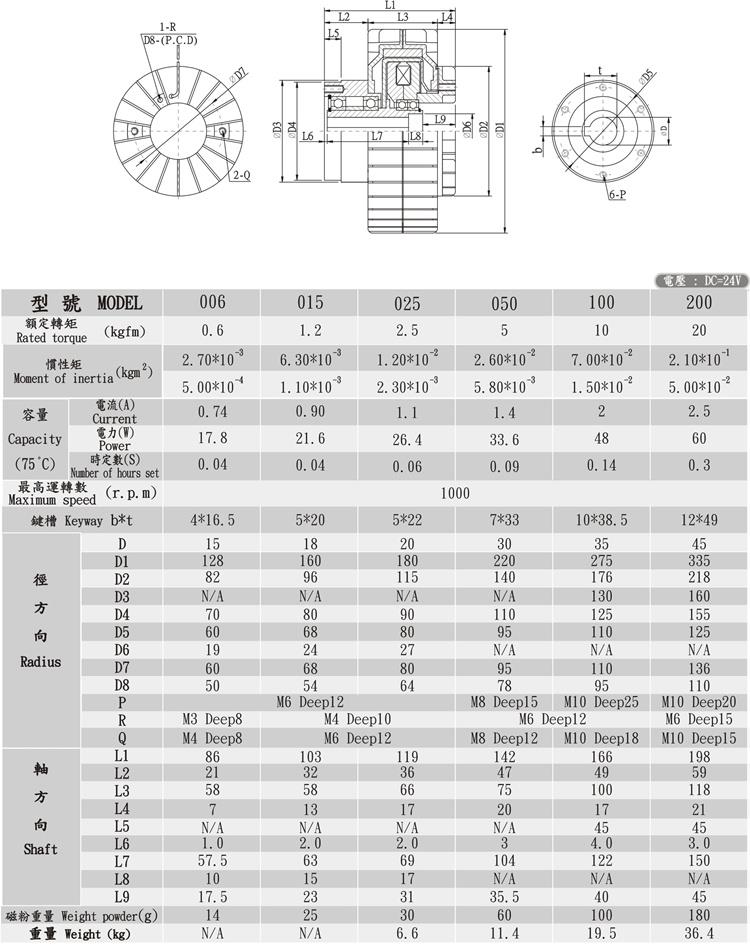

PRE-A2 Hollow Shaft Inner Shell Rotating Magnetic Powder Clutch

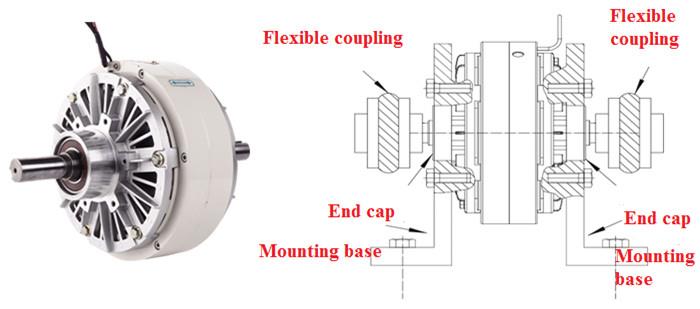

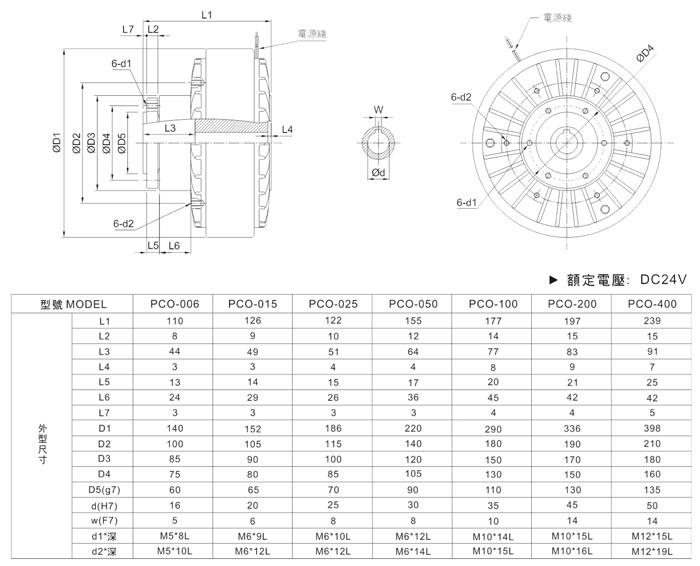

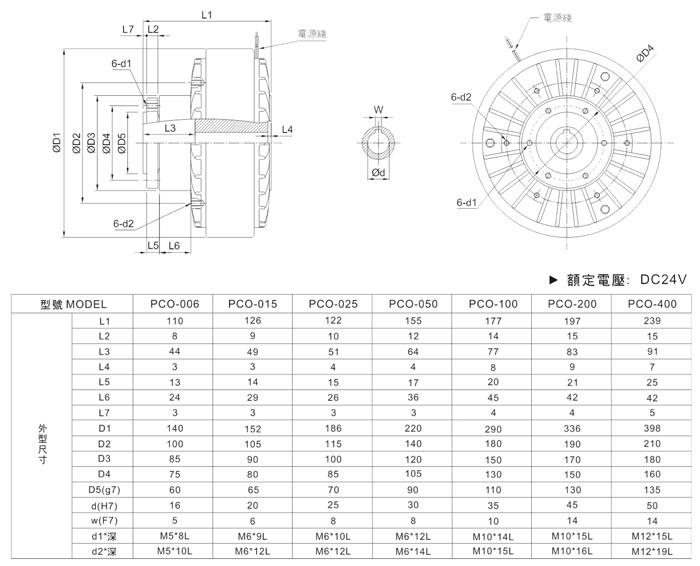

POC rotating magnetic powder clutch

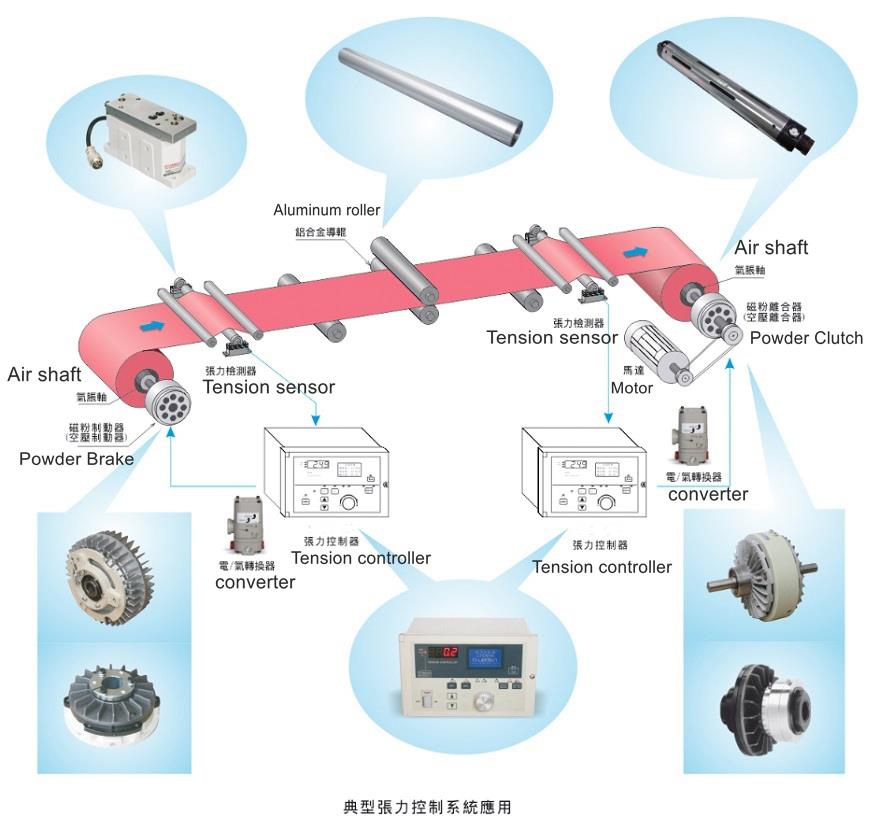

The Schematic Diagram of powder clutch,tension control, web guide system and other parts on equipment.

What should you pay attention to before using the magnetic powder clutch for the first time?

The

magnetic powder brake can transmit a certain torque regardless of the

slip. The magnetic powder brake is a multi-purpose, superior performance

automatic control component with fast response, simple structure, no

pollution, no noise, no impact vibration saving. Advantages of energy,

etc. Before the magnetic powder brake is officially operated or after

the device is moved, it must be evenly operated to be officially

operated. The maintenance of magnetic powder brakes must follow the

principle of “maintenance and maintenance, prevention first”, so that

regular maintenance and enforcement are carried out, and the

relationship between use, maintenance and repair is correctly handled.

It is not allowed to use only no maintenance, only repair and no

maintenance. Smooth torque and uniform operation are as follows: In the

non-excited state, the drive side is rotated as fast as possible (after

1800 rpm) for about 1 minute, and the excitation current is set at

1/4-1/5 of the rated value. Side, on the one hand, open in 5 seconds,

close in 10 seconds, about 20 times of excitation.

Before the

magnetic powder clutch is used for the first time, it is rated at 30% of

rated current. After 10 seconds of operation, the power is turned off

and then energized. Repeated several times to ensure the fluidity and

uniform distribution of the magnetic powder. The magnetic powder clutch

often causes the magnetic powder to gather somewhere during

transportation. There may be a "catch" phenomenon, the brake can be

flipped as a whole, the magnetic powder clutch drive shaft is

horizontally mounted, the mounting accuracy of the drive shaft and the

coupling is H8/f8, the hammer is not allowed to be assembled, and the

magnetic powder clutch is not supported. Radially subjected to the main

drive force installation method, such as cantilever mounting pulleys,

gears, etc., to loosen the magnetic powder, or use a lever to move. In

order to prevent the precipitation of magnetic powder during

transportation, the internal component of the magnetic powder clutch is

the rotor, and the external component is the outer casing assembly. The

magnetic powder brake above CZ-50 is poured out after the test, and the

magnetic powder can be gradually injected from the magnetic powder hole

during the running-in process.

Packing

Order Details

Item Name | Magnetic Powder Clutch |

MOQ(Minimum Order Quantity) | 1Pc |

Lead time | 3-5 days after receiving the deposit |

Calculated Weight | According to different models |

Package | Carton/Wooden Box |

Price Term | EXW,FOB, CIF, etc |

Payment term | TT,L/C,Western Union |

Country of Origin | China |

Hot Tags: particle clutches, China, manufacturers, suppliers, factory, quotation, pricelist, buy