Aluminum Roller Conveyor

"Aluminum guide roller", also known as "aluminum alloy guide roller", is made of high-quality aluminum alloy material, through the mold, into a tube type, with a rib structure inside, and high strength. The outer diameter has various specifications such as Φ22m-Φ320mm. The...

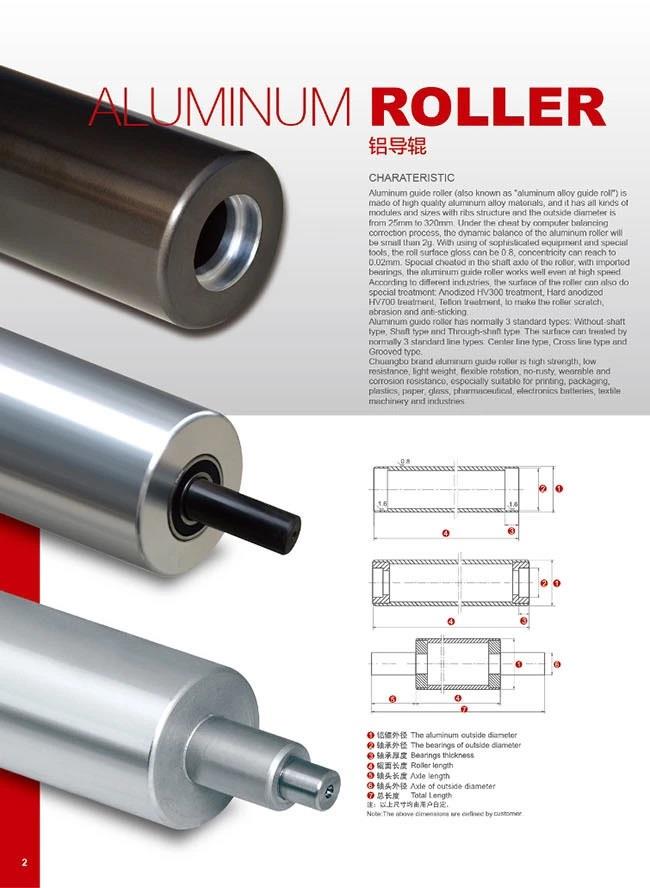

"Aluminum guide roller", also known as "aluminum alloy guide roller", is made of high-quality aluminum alloy material, through the mold, into a tube type, with a rib structure inside, and high strength. The outer diameter has various specifications such as Φ22m-Φ320mm. The whole axis is corrected by the computer dynamic balance, so that the balance can reach the highest precision within 2g. Using the precision equipment and special tools, the gloss of the roller surface can reach 0.8 and the coaxiality can reach 0.02mm. The shaft end is treated with special technology and matched with imported bearings. It can be easily operated at high speed. According to the different needs of the industry, the roller surface can also be specially treated: anodized HV300 treatment, anode hard oxidation HV700 treatment, mirror anode hard oxidation HV700, Teflon treatment, so that it has good scratch resistance and resistance Grinding, anti-adhesive properties.

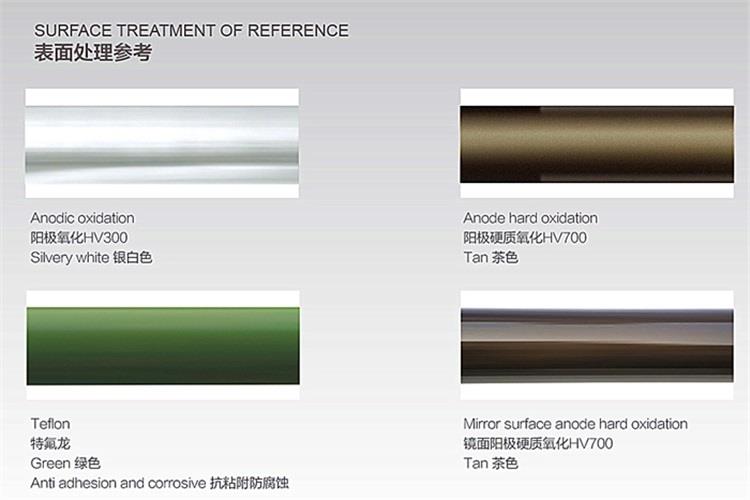

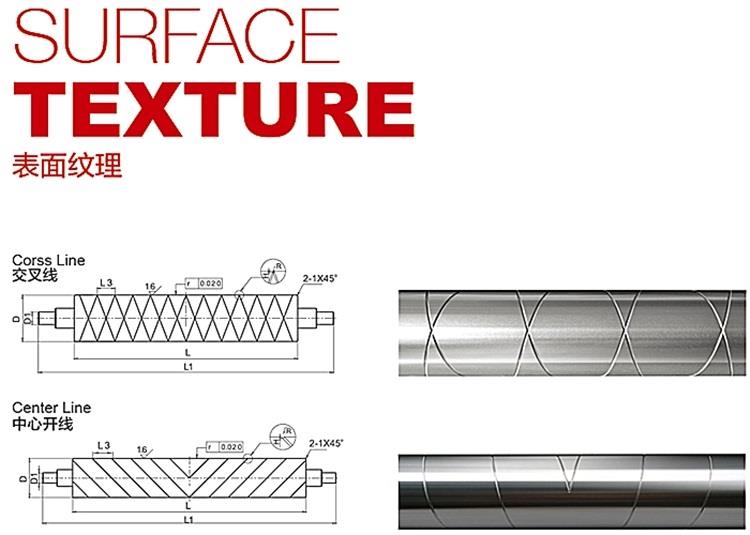

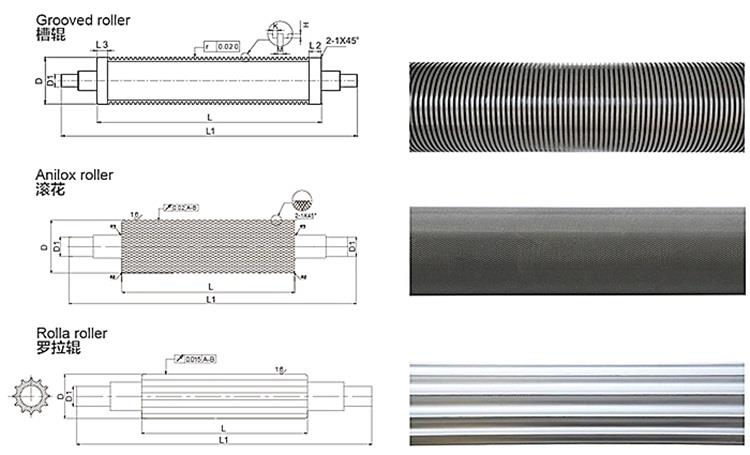

Aluminum guide roller surface treatment

A. Ordinary anodizing (natural or white) surface hardness HV300

B. High hardness anodizing (brown) surface hardness HV700

C. Sandblasting (20 mesh \ 60 mesh \ 80 mesh \ 120 mesh) ordinary or hard oxidation

D. Teflon (green or black) surface hardness HV700

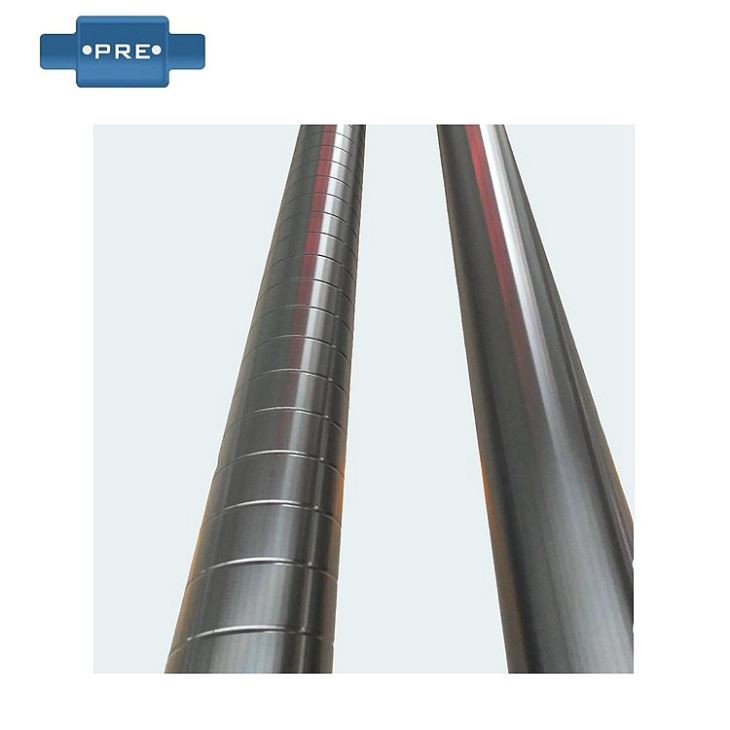

E. knurling (tooth pitch according to the drawings)

F. Groove rolls, cooling rolls, etc. are produced according to the drawings.

G. Dynamic balance G2.5 (within 3g), G6.3 (within 10g)

Aluminum guide roller has high strength, low resistance, light weight, flexible rotation, no rust, wear and corrosion resistance, especially suitable for printing, packaging, plastics, paper, fiberglass, pharmaceutical, electronic battery, textile and other machinery industries. Various coil processing industries.

|

O.D(mm) |

I.D(mm) |

Wall Thickness |

Stiffener |

|

Ф32 Ф33 Ф40 |

Ф24 Ф27 Ф34 |

4:00 3:00 3.00 |

8 |

|

Ф40.5 Ф42.5 serrated roller Ф43.8 |

Ф31 Ф30 Ф34.5 |

5.00 4.50 5.00 |

|

|

Ф47 Ф50.5 Ф51 with groove |

Ф40.8 Ф40.5 Ф38 |

3.00 5.00 6.50 |

8

6 |

|

Ф55 Ф58.5 Ф61 |

Ф46.5 Ф51.5 Ф51 |

4.50 3.50 4.90 |

6 8 6 |

|

Ф70 serrated roller Ф71 Ф71 |

Ф46 Ф63.2 Ф61 |

7.20 4.50 3.50 |

8 7 |

|

Ф74.5 Ф75.5 Ф80 |

Ф60 Ф66 Ф73 |

7.20 4.50 3.50 |

8 8 |

|

Ф81 Ф81 Ф80 |

Ф72.5 Ф71 Ф69 |

4.30 5.00 5.50 |

8 8 8 |

|

Ф90 Ф99 Ф101 |

Ф81 Ф90.5 Ф92 |

4.50 4.30 4.50 |

8 8 7 |

|

Ф101.5 Ф101 Ф101 |

Ф91.5 Ф89 Ф86.3 |

4.50 11.00 11.00 |

7 8 8 |

|

Ф111 Ф115 Ф116 |

Ф102 Ф93 Ф94 |

4.50 11.00 11.00 |

7 8 |

|

Ф120.5 Ф121.5 Ф130.5 |

Ф105.5 Ф111.5 Ф118 |

7.50 5.00 6.25 |

9 |

|

Ф140 Ф145 Ф151.5 |

Ф120 Ф123 Ф139.5 |

10.00 11.00 6.20 |

8 7 8 |

|

Ф151.5 Ф153 Ф162 |

Ф131.5 Ф121 Ф148 |

10.00 11.00 7.00 |

9 |

|

Ф184 Ф203 |

Ф168 Ф179 |

8.00 12.00 |

|

|

Ф150.5 Ф151 Ф200 Ф320 |

Ф136.5 Ф140 Ф186 Ф296 |

7.00 5.50 7.00 12.00 |

10 |

There are some things that should be paid attention to during the use of shaft-free aluminum alloy guide rollers.

Before using the aluminum alloy guide roller air expansion shaft, we must first fully understand the structure, performance and characteristics of the air expansion shaft, and understand the type, specification, type and adaptation of the air expansion shaft. Be proficient in the laying, installation methods, and skills of the inflation shaft, and understand the precautions in the construction, such as the bending radius of the inflation shaft, the arrangement of the laying, how to enter and exit the distribution box, the cabinet, how to pay attention to eliminate the eddy current . Familiar with the accessories of the inflatable shaft, as well as the installation and use of each accessory. Understand the special tools required for the installation of the expansion shaft and be familiar with the method of use. Familiar with the construction drawings and site conditions, and develop detailed construction plans. During the laying process of the inflation shaft, or after laying and installing, it is strictly forbidden to drag or collide the live electric welding faucet wire on the inflation shaft, because the electric welding faucet will be connected with the copper sheath of the inflation shaft (equivalent The welding spark is generated on the grounding wire, so that the copper sheath is melted, which causes holes in the copper sheath of the inflation shaft, causing moisture in the air to be absorbed by the magnesium oxide insulation, and the insulation resistance of the inflation shaft is lowered. Sometimes, because the fault segment that creates the hole is not found, it is mistaken to think that there is a problem with the product of the inflation shaft manufacturer. This must be taken seriously.

During the laying and installation process, the insulation of the air-expansion shaft should be measured and the problems should be dealt with in a timely manner. Before and after the air-filled shaft is laid and before and after the production of the terminal and the intermediate joint, the insulation resistance of the air-expansion shaft should be measured several times and compared before and after to ensure that the air-expansion shaft quality of each installation process is intact. At the same time, regardless of the interruption or suspension of the expansion shaft, or to be placed for a period of time before construction, the end of the expansion shaft must be timely in order to avoid the moisture of the magnesium oxide insulation. After the terminal head and the intermediate head of the air-expansion shaft are fabricated, an insulation test is performed immediately. After 24 hours, the test is repeated. If the inflation shaft head is not damp, the cover layer is not damaged. In the actual test, the megohmmeter is used. The pointer should point to “∝”, which indicates that the inflation shaft has good insulation properties. If the insulation resistance value is found to decrease in the second test, the fault point should be found. Generally speaking, the fault point of the aluminum alloy guide roller is at the terminal or the intermediate joint. When searching, the flame can be used in the lower part of the terminal. The two ends of the joint are heated, and the insulation resistance value of the inflation shaft is measured. After a few seconds of heating, the insulation resistance value drops sharply, indicating that there is a problem with the terminal or the middle head. At this time, it should be removed and redone until qualified. . If the insulation resistance does not change, check other terminals or intermediate heads on the line until the point of failure is found and repaired as described above. After the expansion shaft is laid, if there is no intermediate joint, the terminal can be directly used. If there is an intermediate joint, the intermediate joint should be made first, otherwise the trouble of checking the phase will be increased. The copper sheath of the inflatable shaft can be used for grounding and must be grounded.

Application

Packing

Order Details

|

Item Name |

Aluminum roller conveyor |

|

MOQ(Minimum Order Quantity) |

1PC |

|

Lead time |

10-15 days after receiving the deposit |

|

Calculated Weight |

Need to count |

|

Package |

Wooden Box/Pallet packing/according to clients' demand |

|

Price Term |

EXW,FOB, CIF, etc |

| Payment term | TT,L/C,Western Union |

| Country of Origin | China |

Hot Tags: aluminum roller conveyor, China, manufacturers, suppliers, factory, quotation, pricelist, buy