Fast Response And High Precision Ultrasonic Sensor

Photoelectric guide manufacturers believe that photoelectric sensors are widely used and developed rapidly, mainly because they have the following characteristics: 1. The detection distance is long. If the detection distance of 10 m or more is retained in the through-beam type, detection that...

Photoelectric guide manufacturers believe that photoelectric sensors are widely used and developed rapidly, mainly because they have the following characteristics:

1. The detection distance is long. If the detection distance of 10 m or more is retained in the through-beam type, detection that cannot be realized by other detection means (magnetic, ultrasonic, etc.) can be realized.

2. There are fewer restrictions on detecting objects. Since the shading and reflection caused by the detection object are the detection principle, the detection object is not limited to the metal material like the proximity sensor, and the photoelectric sensor can detect almost all objects such as glass, plastic, wood, liquid, and the like.

3. The response time is short. The light itself is high speed, and the sensor circuit is composed of electronic parts, so it does not contain mechanical working time and the response time is very short. Easy to adjust. In the type of visible light, the light beam is visible to the eye, and the photoelectric guide system can adjust the position of the detected object.

4. High resolution. High resolution can be achieved by concentrating the beam of light at small spots by advanced design techniques or by forming a special light-receiving optics. Small object detection and high-precision position detection are also possible.

5, can achieve non-contact detection. The detection can be performed without mechanical contact with the detection object, so that damage to the detection object and the sensor is not caused. Therefore, the sensor can be used for a long time. 6, can achieve color discrimination. The reflectance and the absorptivity of light formed by detecting an object differ depending on the wavelength of the light to be emitted and the color combination of the detected object. With this property, the color of the detected object can be detected.

Since the objects in the textile processing process are various fibers or yarns, they are a flexible object that is easily deformed by an external force. Therefore, in order to detect changes in some parameters during processing, if a normal contact sensor is used, the detection result may have an error due to contact, and the photoelectric detection is non-contact, which does not change the original state of the yarn. Photoelectric sensor is a device that converts the amount of photoelectric energy into electric quantity. It converts non-electricity such as yarn, yarn defect, etc. into a change in electric quantity, thereby realizing detection of these non-electric quantities, because the photoelectric sensor is a non-contact measurement. It makes it widely used in textile production.

Photoelectric guide Sensor Manufacturers Analyze the Application of Photoelectric Sensors in Automated Production Lines

The application of photoelectric sensors in automated production lines. Photoelectric sensors generally consist of a light source, an optical path, and a photovoltaic element. The photoelectric detection method has the advantages of high precision, fast response, non-contact, etc., and has many parameters to be measured, the sensor has a simple structure, a flexible form and a small volume. In recent years, with the development of optoelectronic technology, photoelectric sensors have become a series of products, and their varieties and output are increasing. Users can select various specifications according to their needs and obtain wide applications in various light industrial automata.

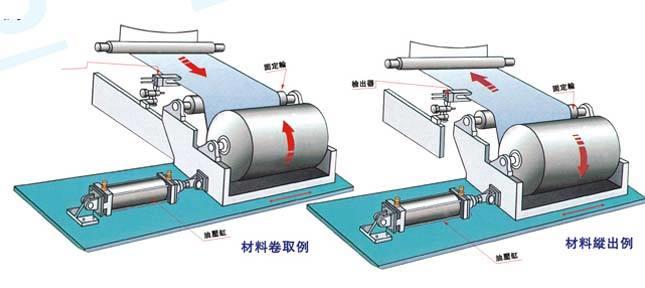

1. Photoelectric strip deviation detector. The strip deviation detector is used to detect the size and direction of the strip material in the correct position during processing, thereby providing a correction signal for the rectification control circuit, which is mainly used in the production process of printing, dyeing, paper feeding, film and tape.

Principle of photoelectric strip deviation detector: The light from the light source is concentrated by the lens 1 into a beam of light, which is directed to the lens 2 and then concentrated on the photoresistor. On the way that the parallel beam reaches the lens 2, part of the light is blocked by the strip under test, reducing the amount of light transmitted to the photoresistor.

2, packaging filling height detection. The volumetric method is used to measure the finished product of the package. In addition to the certain error range requirements for the weight, there are certain requirements for the filling height to ensure the appearance quality of the product. The finished product that does not meet the filling height will not be allowed to leave the factory. When the filling height h deviation is too large, the photoelectric connector has no electrical signal, that is, the packaged article is pushed out by the actuator for processing.

3. Photoelectric color quality detection. If the packaged item is white, the quality will be poor, and some will appear yellow. Before the product is packaged, the color will be detected by photoelectricity. When the item is yellow, there will be a comparison of the voltage difference output, and the solenoid valve will be connected. Blow out the yellowed items.

Order Details

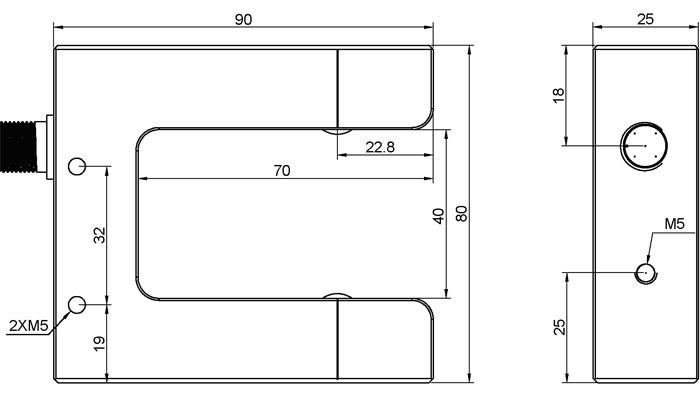

Item Name | PS-400S Photoelectric Sensor |

MOQ(Minimum Order Quantity) | 1pc |

Lead time | 1-2 days after receiving the deposit |

Calculated Packing Size | 15cm*10cm*10cm,1kg/pc |

Package | Carton/Wooden Box |

Price Term | EXW,FOB, CIF, etc |

Payment term | TT, L/C,Western Union |

Country of Origin | China |

Hot Tags: fast response and high precision ultrasonic sensor, China, manufacturers, suppliers, factory, quotation, pricelist, buy