Aluminum Roller Track

The aluminum alloy manual roller has the advantages of high unit energy, light weight, small inertia, and suitable look of mild and rust. it's far broadly used in embossing printing, coating, winding, blown film, lamination, coating, slitting, paper making, and textile. awaiting the...

The aluminum alloy manual roller has the advantages of high unit energy, light weight, small inertia, and suitable look of mild and rust. it's far broadly used in embossing printing, coating, winding, blown film, lamination, coating, slitting, paper making, and textile. awaiting the production line.

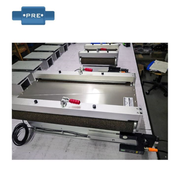

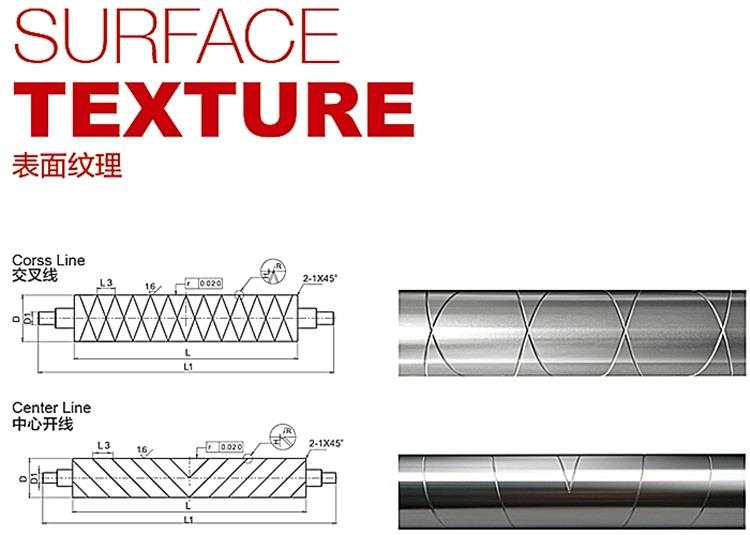

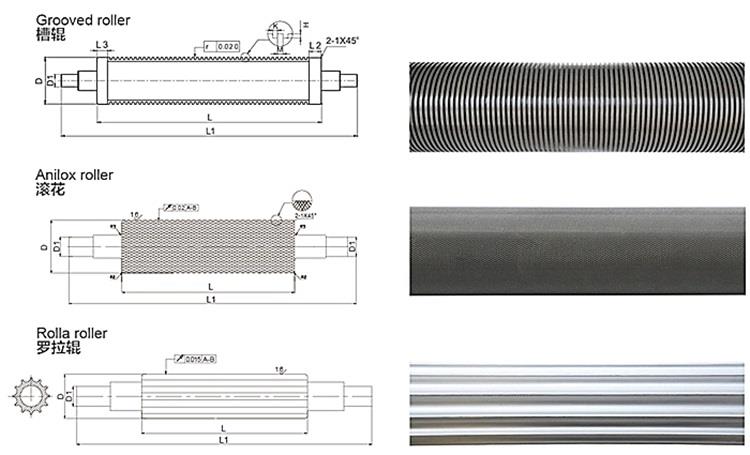

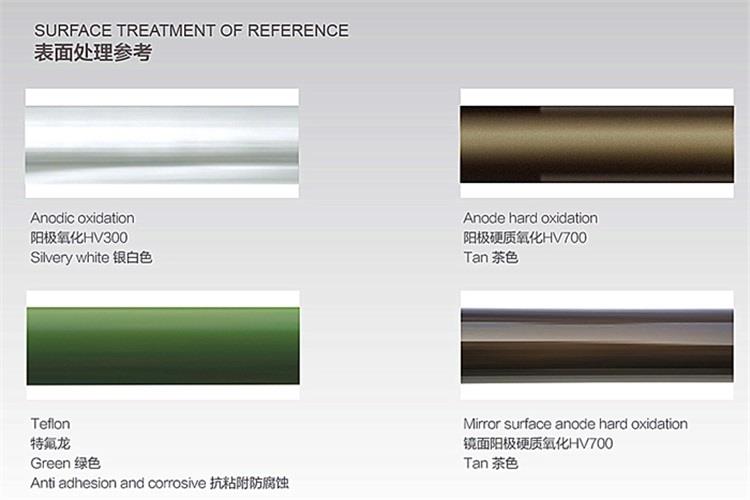

The construction of the aluminum alloy guide rolls may be more or less divided into:

(1) hole aluminum curler: the inner bearing kind shape, the bearing is set up at the bearing holes in the two faces.

(2) coupling aluminum roller: the roller frame is hooked up to the metal shaft or the chrome steel shaft quit at both ends, and is an integrated structure.

(3) water-passing aluminum roll: cooling or heating liquid enters and exits thru both facets and circulates inside the roll body.

(four) unique rolls: diverse unique creation rolls processed as proven.

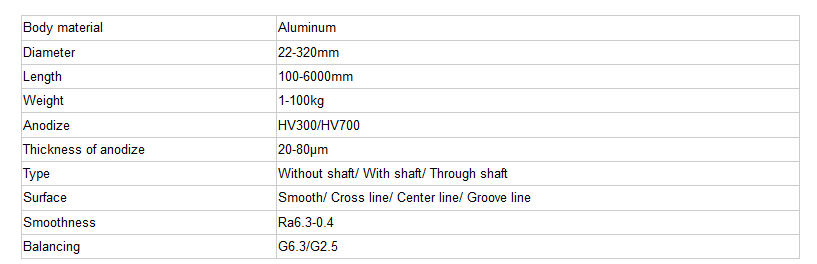

O.D(mm) | I.D(mm) | Wall Thickness | Stiffener |

Ф32 Ф33 Ф40 | Ф24 Ф27 Ф34 | 4:00 3:00 3.00 |

8 |

Ф40.5 Ф42.5 serrated roller Ф43.8 | Ф31 Ф30 Ф34.5 | 5.00 4.50 5.00 | |

Ф47 Ф50.5 Ф51 with groove | Ф40.8 Ф40.5 Ф38 | 3.00 5.00 6.50 | 8

6 |

Ф55 Ф58.5 Ф61 | Ф46.5 Ф51.5 Ф51 | 4.50 3.50 4.90 | 6 8 6 |

Ф70 serrated roller Ф71 Ф71 | Ф46 Ф63.2 Ф61 | 7.20 4.50 3.50 |

8 7 |

Ф74.5 Ф75.5 Ф80 | Ф60 Ф66 Ф73 | 7.20 4.50 3.50 |

8 8 |

Ф81 Ф81 Ф80 | Ф72.5 Ф71 Ф69 | 4.30 5.00 5.50 | 8 8 8 |

Ф90 Ф99 Ф101 | Ф81 Ф90.5 Ф92 | 4.50 4.30 4.50 | 8 8 7 |

Ф101.5 Ф101 Ф101 | Ф91.5 Ф89 Ф86.3 | 4.50 11.00 11.00 | 7 8 8 |

Ф111 Ф115 Ф116 | Ф102 Ф93 Ф94 | 4.50 11.00 11.00 |

7 8 |

Ф120.5 Ф121.5 Ф130.5 | Ф105.5 Ф111.5 Ф118 | 7.50 5.00 6.25 |

9 |

Ф140 Ф145 Ф151.5 | Ф120 Ф123 Ф139.5 | 10.00 11.00 6.20 | 8 7 8 |

Ф151.5 Ф153 Ф162 | Ф131.5 Ф121 Ф148 | 10.00 11.00 7.00 |

9 |

Ф184 Ф203 | Ф168 Ф179 | 8.00 12.00 | |

Ф150.5 Ф151 Ф200 Ф320 | Ф136.5 Ф140 Ф186 Ф296 | 7.00 5.50 7.00 12.00 |

10 |

How to improve the service life of the guide roller. Through the comprehensive evaluation of the plasma alloy guide rolls, it can be known that the application of the plasma cladding technology on the guide rolls of the rolling mill can significantly improve the service life of the rolling mill guide rolls, thereby reducing the cost of guide roller handling and loading, and reducing the labor intensity and guidance of frequent replacement. The waste of steel rolling work time caused by the disassembly and handling of the roller can increase the amount of steel rolling, save a large amount of high-quality steel, and also reduce the safety accident caused by the damage of the guide roller.

When the aluminum guide roll is glazed, the surface area of the rubber is greatly reduced, and the transfer performance to the ink and the fountain solution is deteriorated, resulting in difficulty in printing.

The following set of data can illustrate the severity of glazing:

Ordinary rubber roller: After the printing machine reaches 1 million revolutions, the rubber surface begins to glaze.

High-quality rubber roller: After the printing machine runs 5 million revolutions, the rubber surface area is less than 30%.

High-quality glazed rubber roller: After 30 million revolutions of printing machine, the rubber surface area can maintain more than 70% of the original.

The aluminum guide roller is glazed to make the surface of the aluminum guide roller hard, the elasticity is reduced, and the printing pressure is increased, which makes it difficult to adjust the pressure of the ink roller and the water roller.

It directly leads to insufficient density of printed ink, slow drying, unstable ink balance, increased paper waste and difficulty in cleaning aluminum guide rolls.

Application

Order Details

Item Name | Aluminum roller |

MOQ(Minimum Order Quantity) | 1PC |

Lead time | 10-15 days after receiving the deposit |

Calculated Weight | Need to count |

Package | Wooden Box/Pallet packing/according to clients's requirement and demand |

Price Term | EXW,FOB, CIF, etc |

| Payment term | TT,L/C,Western Union |

| Country of Origin | China |

Hot Tags: aluminum roller track, China, manufacturers, suppliers, factory, quotation, pricelist, buy