Chuck Shaft

The air-expansion shaft is easy to use and can be wound freely. It can complete the tight fixation of the inflation shaft and the coil tube to achieve a good winding effect. Similarly, the deflation can take only 2 seconds to make the inflation shaft and the coil tube. Separation, to facilitate...

The air-expansion shaft is easy to use and can be wound freely. It can complete the tight fixation of the inflation shaft and the coil tube to achieve a good winding effect. Similarly, the deflation can take only 2 seconds to make the inflation shaft and the coil tube. Separation, to facilitate the removal of the expansion shaft from the coil. The air-filling shaft matching clamp is suitable for the coiled tube with large inner diameter and the safety chuck. It can make the folding between the air-expansion shaft and the machine convenient and convenient, saving time, labor and cost.

The gas-increasing shaft mainly passes through the principle of expansion and contraction, and reaches the inflation shaft to expand the paper tube to receive the material, and discharges the material after deflation. Good shrinkage performance and not easy to blast. Suitable for items with a large inner diameter of the coiled tubing.

1. When installing the air-expansion shaft, the first thing to be determined is that the compressor that controls the air pressure is in a stable state, and a filter is directly installed between the compressor and the air-expansion shaft to prevent impurities from clogging the air pipe, thereby causing air leakage. ; Zhejiang steam rising shaft.

2. The direction of entry of air should be vertical to prevent damage to the valve;

3. When exhausting, it is necessary to use the standard matching exhaust port, and it is forbidden to use tools such as sharp hammer to avoid air leakage;

4. Pressure gauge and pressure control device should be installed, and the air pressure must be controlled within the range of 3-8kg/cm; Zhejiang steam rising shaft.

5. Be careful to avoid straining the valve.

Technique parameter

|

Model |

Inner Diameter of Paper Tube |

Shaft Diameter Before Expanding |

Shaft Diameter After Expanding |

|

1" Shaft |

Φ25.4mm |

Φ24.5mm |

Φ27.5mm-Φ28mm |

|

1.5" Shaft |

Φ38mm |

Φ37mm |

Φ41mm |

|

2" Shaft |

Φ50mm |

Φ49mm |

Φ53mm |

|

3" Shaft |

Φ76.2mm |

Φ74mm-Φ74.5mm |

Φ82mm |

|

4" Shaft |

Φ102mm |

Φ100mm |

Φ108mm |

|

6" Shaft |

Φ152.4mm |

Φ150mm |

Φ158mm |

|

8" Shaft |

Φ203.2mm |

Φ200mm |

Φ210mm |

|

10" Shaft |

Φ254mm |

Φ250mm |

Φ260mm |

|

12" Shaft |

Φ304.8mm |

Φ300mm |

Φ312mm |

Maintenance and application of the air shaft

When the air shaft is repaired, the paper tube should be loosened. When the paper is pressed by the sliding air core on the air nozzle, the key strip will return to the original state, and the external parts (such as a round paper tube) can be taken out. .

1) Neat: tools, workpieces, and accessories are placed neatly; safety protection devices are complete; line piping is complete.

2) Cleaning: The inside and outside of the equipment are clean; all sliding surfaces and screws, gears, racks, etc. are free of oil and dirt; no leakage, no leakage, no leakage, no leakage; cleaning of the chips.

3) Lubrication: Oil is changed on time, oil quality meets the requirements; oil pot, oil gun, oil cup, linoleum, oil line are clean and complete, the oil mark is bright, and the oil path is smooth.

4) Safety: Analysis of the air-expansion shaft maintenance factory, implementation of the fixed-machine setting and handover system; familiar with the equipment structure and compliance with operational procedures, rational use of equipment, careful maintenance of equipment, to prevent accidents.

Scope of application:

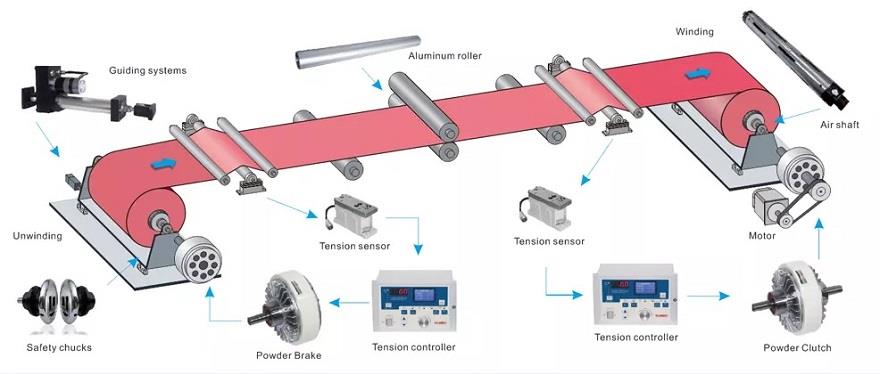

1. The pneumatic reel, also known as the air-up shaft, is based on the principle of air compression, which changes the outer diameter of the shaft, and then closely combines with the coiled tubing to facilitate the transmission and winding of the whole roll of material, and promotes the rational, simple and precise operation on the production line. Sex and automation.

2. When the air is injected into the interior for expansion, the parts in the shaft body are expanded and pushed out, and the outer diameter of the shaft body is increased, so that the coiled tube is fully and accurately fixed to the shaft body.

3. When the internal air is released, the parts that are expanded and extruded are retracted, and the shaft can be easily taken out. Slatted air expansion shaft.

4. The main body of the shaft is made of high-stress steel or aluminum alloy, and the inner expansion body is made of special imported synthetic rubber.

5, and a variety of structural forms: the center guide key bar type gas rise shaft or slat type air expansion shaft; surface rotation key bar type or slat type; independently adjust the slip type convex key type air expansion shaft.

Packing

Order Details

|

Item Name |

chuck shaft |

|

MOQ(Minimum Order Quantity) |

1Pc |

|

Lead time |

15-18 days after receiving the deposit |

|

Calculated Weight |

Depend on dimension |

|

Package |

Carton/Wooden Box |

|

Price Term |

EXW,FOB, CIF, etc |

|

Payment term |

TT,L/C,Western Union |

|

Country of Origin |

China |

Hot Tags: chuck shaft, China, manufacturers, suppliers, factory, quotation, pricelist, buy