Differential Air Shaft

The working principle of the slip shaft is: the center air pressure slip shaft is a tension adjustment type slip shaft, and the slip ring is independently slipped. Taking the precision air core ventilation main shaft as the core, the piston is used to push the piston in the cavity, so that the...

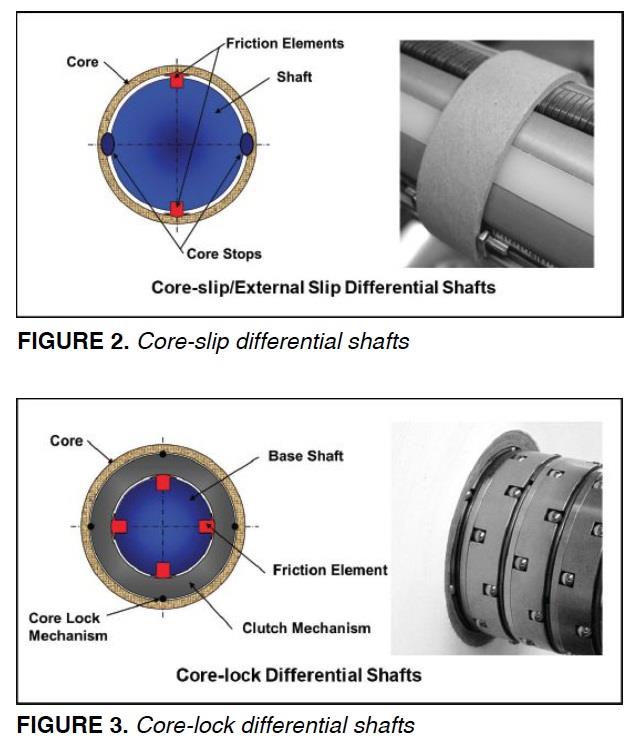

The slip shaft, also known as the friction shaft. It is applied to the reel of the slitting machine, and it is also used for the reel in special occasions. The purpose is to use the principle of slipping of each slip ring on the slip shaft, so that the multiple reels on the shaft always maintain the constant tension retracting and unwinding.

The slitter is a device that divides a roll of roll into multiple rolls and is widely used. The function of the take-up reel is to wind the multi-roll material after striping of various materials from the core to the outer layer, evenly and neatly, and to wind on one or two shafts under constant tension. However, due to the uneven thickness of the material itself, there is a certain thickness error, and after the coil is continuously wound up, the diameter of each coil produces a larger accumulation error. This results in a greater difference in the take-up speed of each strip and a greater difference in tension. The winding material is different in tension, and the end surface is uneven. In severe cases, the material is damaged due to excessive pulling force, especially the polyester film, which not only has large thickness error, but also has large elongation and is easy to be deformed due to tensile deformation.

1. Depending on the material and quality of the paper core, the slip ring must be taken every week to one month to clean up the dust, paper scraps and other debris in the slip ring to ensure the smoothness of the steel ball and the key strip. Wipe the debris on the mandrel and apply an appropriate amount of white oil on the wool felt to assemble the slip shaft as it is.

2. It is recommended to replace the wool felt and airbag for half a year. Due to the different torque of different materials, it is found that the wool felt is light and hard in use, and should be replaced immediately, otherwise it will affect the torque.

3. Do not overload the slip-type air expansion shaft, which will cause the mandrel to deform and break.

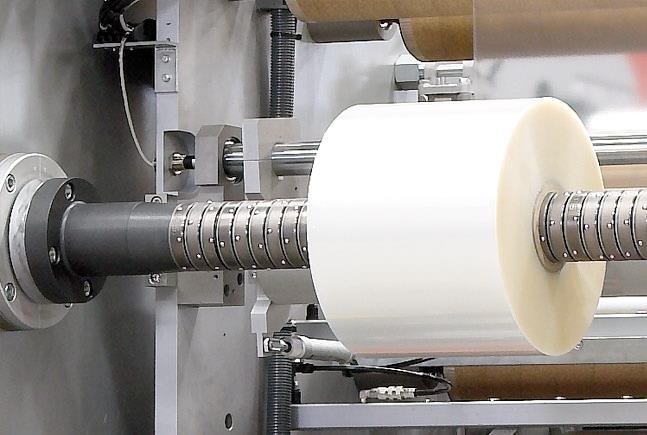

Applicaton:

Technique parameter

Model | Paper tube inner diameter | Shaft diameter before expanding | Shaft diameter after expanding |

2" Differential Shaft | Φ50.8mm | Φ50mm | Φ52mm |

3" Differential Shaft | Φ76.2mm | Φ75mm-Φ75.5mm | Φ78.5mm |

6" Differential Shaft | Φ152.4 | Φ151mm | Φ156mm |

Order Details

Item Name | Differential air shaft |

MOQ(Minimum Order Quantity) | 1Pc |

Lead time | 15-18 days after receiving the deposit |

Calculated Weight | Depend on dimension |

Package | Carton/Wooden Box |

Price Term | EXW,FOB, CIF, etc |

Payment term | TT,L/C,Western Union |

Country of Origin | China |

Hot Tags: differential air shaft, China, manufacturers, suppliers, factory, quotation, pricelist, buy