Edge Of The Web Guider

The high-precision, high-speed, high-efficiency coil material automatic processing process of the correction system has higher and higher requirements for the control of the lateral position of the coil. Equipped with a high-performance automatic correction system is the key to improving the...

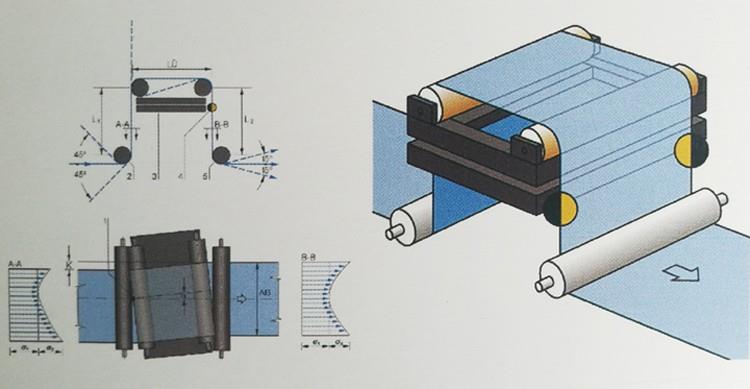

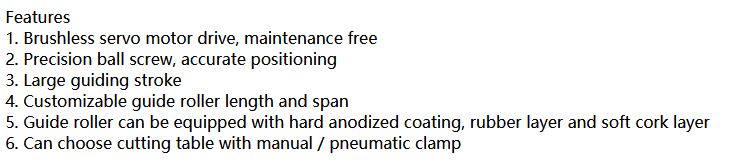

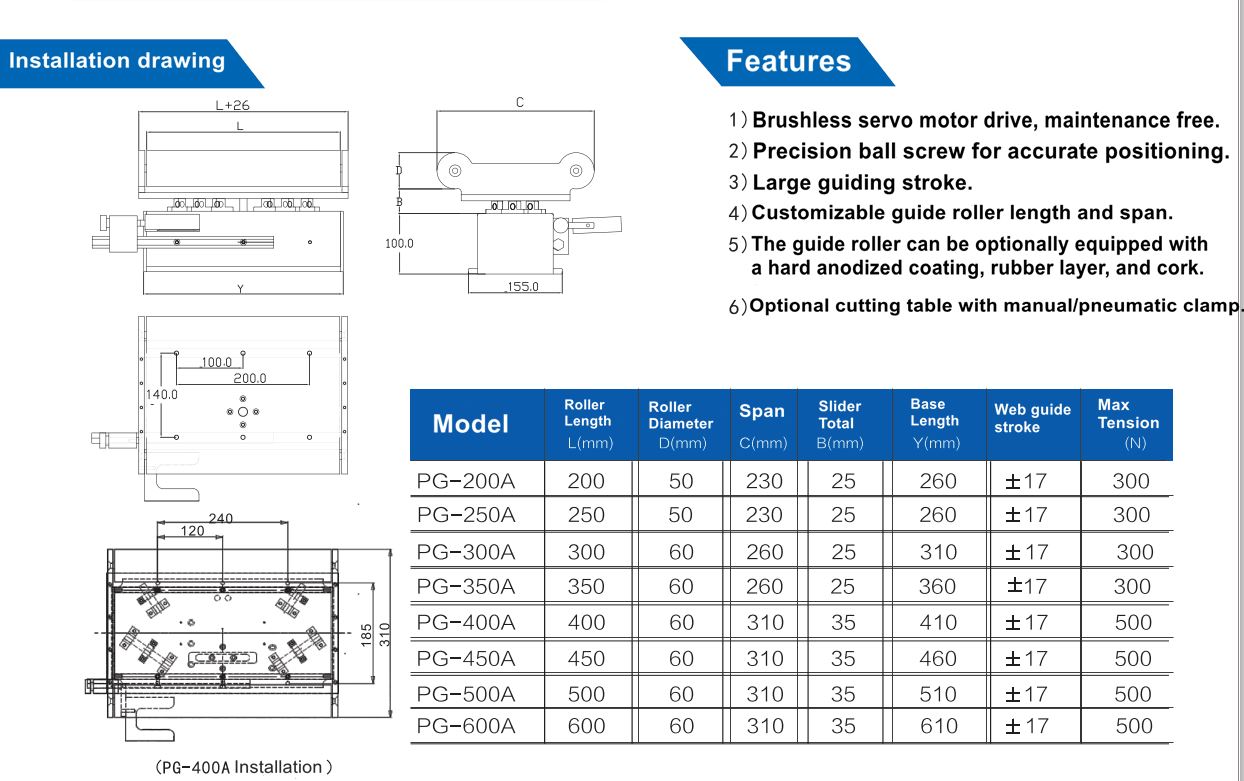

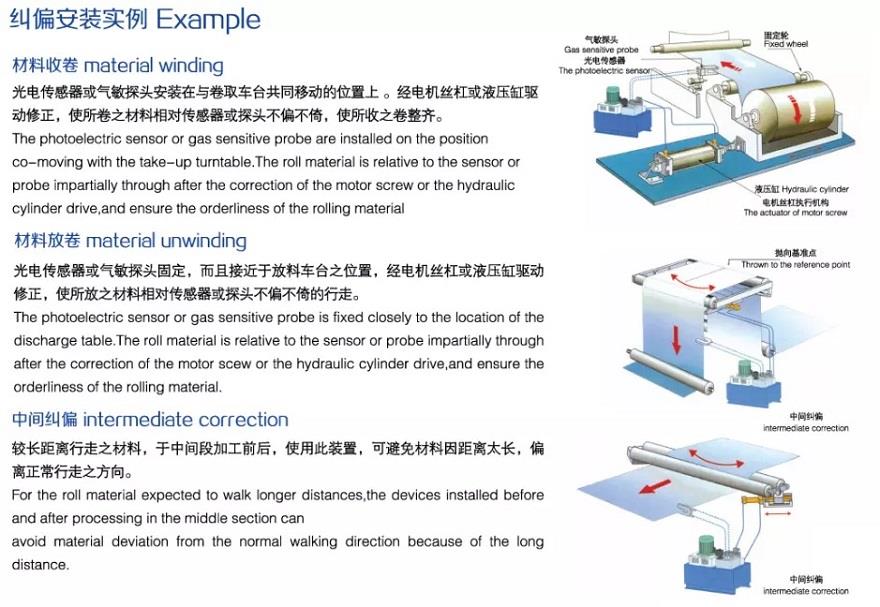

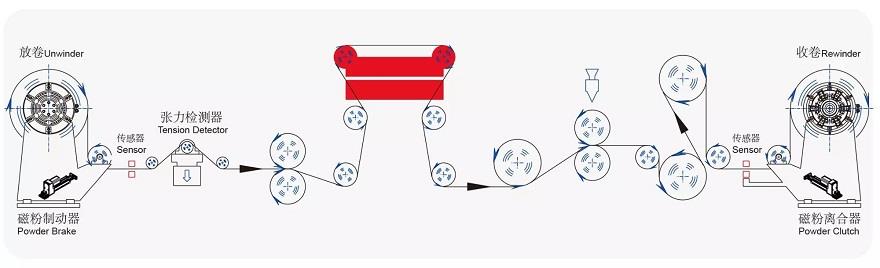

The high-precision, high-speed, high-efficiency coil material automatic processing process of the correction system has higher and higher requirements for the control of the lateral position of the coil. Equipped with a high-performance automatic correction system is the key to improving the production capacity and yield of coils. The coil will produce lateral displacement (running deviation) during travel, unwinding and winding, so the correction system can be installed in the above three positions to control the precise passing of the coil.

The system uses high-speed microprocessor, digital, modular, intelligent circuit design; advanced programming, user-friendly interface, LCD screen display; high-performance components and perfect circuit protection design to make the system run continuously and stably; control system response The time is less than 0.01 seconds; the accuracy of the system itself is up to 0.01mm. During the material winding process, the position of the edge or line is detected by the photoelectric sensor to pick up the edge correction frame or line position deviation signal. Then, the position deviation signal is transmitted to the photoelectric correction controller for logic operation, and a control signal is sent to the mechanical actuator to drive the mechanical actuator to correct the serpentine deviation of the material during operation to ensure linear motion of the material. Optional left and right limit switches prevent the system from running out of control.

Main maintenance work of the guide system

1. The daily maintenance worker shall take the initiative to patrol the installation level and accuracy of the equipment in the district city, and make detailed records for future reference.

2. The correcting system has special requirements for the environment (constant temperature, constant humidity, anti-vibration, dustproof). The enterprise must take corresponding measures to ensure that the accuracy and performance of the equipment are not affected.

3. Precision, rare, and critical equipment Generally, do not disassemble parts, especially optical components, during routine maintenance. When it must be dismantled, it should be carried out by a special repair worker. If abnormal phenomena are found during operation of the equipment, it is necessary to stop immediately and not allow sickness to operate.

4. Operate in strict accordance with the processing range specified in the equipment manual. Super-standard, super-weight, overload, and over-pressure equipment are not allowed. Precision equipment is only allowed to be finished for direct use, the machining allowance should be reasonable, and the castings and blanks should be sandblasted or painted beforehand.

5. The lubricating oil material, wiping material and cleaning agent of the equipment shall be used strictly in accordance with the provisions of the manual, and shall not be used as appropriate. Lubricating oil must pass the test and must be filtered before being added to the tank.

6. Precision, rare equipment should be equipped with a protective cover during non-working hours. If you stop for a long time, wipe, lubricate and run dry regularly.

7. The accessories and special tools of the equipment shall have a special cabinet shelf, be kept clean, prevent rust and bruise, and shall not be borrowed or used for other purposes.

8. Equipment lubrication work is an important part of the on-site use and maintenance of machinery equipment.

Application

Order Details

Item Name | Offset Pivot Guide System |

MOQ(Minimum Order Quantity) | 1pc |

Lead time | 10-15 days after receiving the deposit |

Calculated Packing Size | According to model |

Package | Wooden Box |

Price Term | EXW,FOB, CIF, etc |

Payment term | TT, L/C,Western Union |

Country of Origin | China |

Hot Tags: edge of the web guider, China, manufacturers, suppliers, factory, quotation, pricelist, buy