Factory Produce High-End Slitting Machines For Lithium Battery

Introduction: Product humanized design, practical and strong, easy to operate. Advantages of high-end lithium battery copper foil slitting machine equipment: a. High stability body; 70mm thick plate is adopted for the side plate materials on both sides, and the main body base adopts integral...

Introduction:

Product humanized design, practical and strong, easy to operate.

Advantages of high-end lithium battery copper foil slitting machine equipment:

a. High stability body; 70mm thick plate is adopted for the side plate materials on both sides, and the main body base adopts integral casting heat treatment, which will not deform during use;

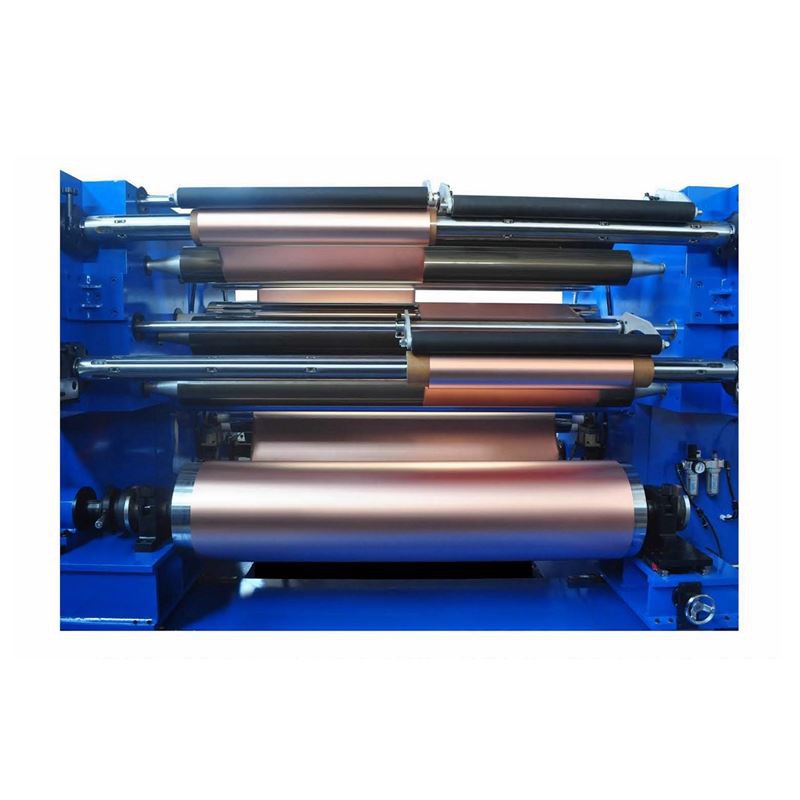

b. High precision; all guide rollers have undergone multiple heat treatment, multiple processing, multiple high-speed dynamic balancing, using famous SKF bearings, all guide rollers have ultra-high rotation accuracy; all guide rollers have ultra-high precision and surface finish It is a mirror level requirement;

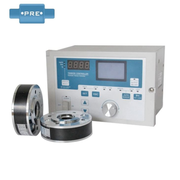

c. High dynamic control system; the whole machine is driven by full servo motor + servo controller, high-end advanced CPU programming, large display screen display, multi-channel closed-loop feedback high dynamic compensation, and the tension of the parent roll can also be stable and the winding tension can be guaranteed. Multi-stage taper output control to effectively control the phenomenon of internal tightness and external looseness;

d. High speed; slitting ultra-thin lithium battery foil is stable at 60-120m / min speed, the highest slitting speed can run continuously above 120m / min; the designed maximum running speed is 150m / min;

e. Low dry noise; the imported precision type is adopted for the motion bearing guides, etc., and the best synchronized synchronous arc tooth belt is used for the transmission belt. The precision of the machine and the low noise under high speed are clearly felt during the operation of the machine.

f. Low copper powder; break the historical traditional cutting mode, ensure high or no copper powder under high-speed conditions through high-precision, high-quality cutting tools, and special layout structure design;

Technique parameter

| Model | 1400-A sheeter | 1550-A sheeter |

| Cutting width range | 150mm -1400mm | 150mm -1550mm |

| Rewinding maximum diameter | Φ350mm | Φ350mm |

| Unwinding maximum diameter | Φ650mm | Φ650mm |

| Rewinding maximum load | Φ800kg | Φ700kg |

| Unloading maximum load | Φ2500kg | Φ2500kg |

| Design speed | 150m / min | 150m / min |

| Cutting original degree range | 0.006-0.03mm | 0.006-0.03mm |

| Cutting accuracy | ± 0.20mm | ± 0.20mm |

| Mechanical footprint (LxWxH) | 2150x3165x1680mm | 2150x3435x1680mm |

| Equipment weight | 7.5T | 7.8T |

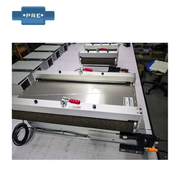

Rewinding and unwinding Part

1. Unwinding adopts large torque servo motor as the active unwinding, the unwinding mechanism can be adjusted in cross direction, the left and right movement range is large, the movement uses grinding precision screw guide rail movement;

2. The upper and lower axes of the winding are driven by independent servo motors, and the N-section taper tension output is provided to effectively prevent the inner looseness and the outer tension, and the winding is not round.

3. The rewinding shaft adopts integral through-key shaft, with high precision, and with moving guide bearing, which is convenient for loading and unloading;

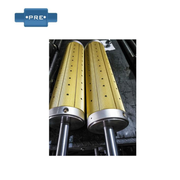

The cutter part

1. The slitting is a high-precision large round knife main drive rotary cutting, the knife edge is flat, low copper powder, and the knife is durable;

2. The tool adjustment is convenient and simple, the adjustment tool does not need to disassemble the tool holder, and the use efficiency is high;

3. The ear material winding is driven by a servo motor, the tension display is adjustable, to avoid the fluctuation of the ear material tension affecting the cost side effect;

Guide roller Part

1. All guide rollers are verified by multiple dynamic balance after high-speed rotation, the balance is within 3g, and the whole shaft runout is within 0.01mm;

2. The surface of all guide rollers is smooth <0.8um mirror processing, which will not scratch the copper foil surface;

Hot Tags: factory produce high-end slitting machines for lithium battery, China, manufacturers, suppliers, factory, quotation, pricelist, buy