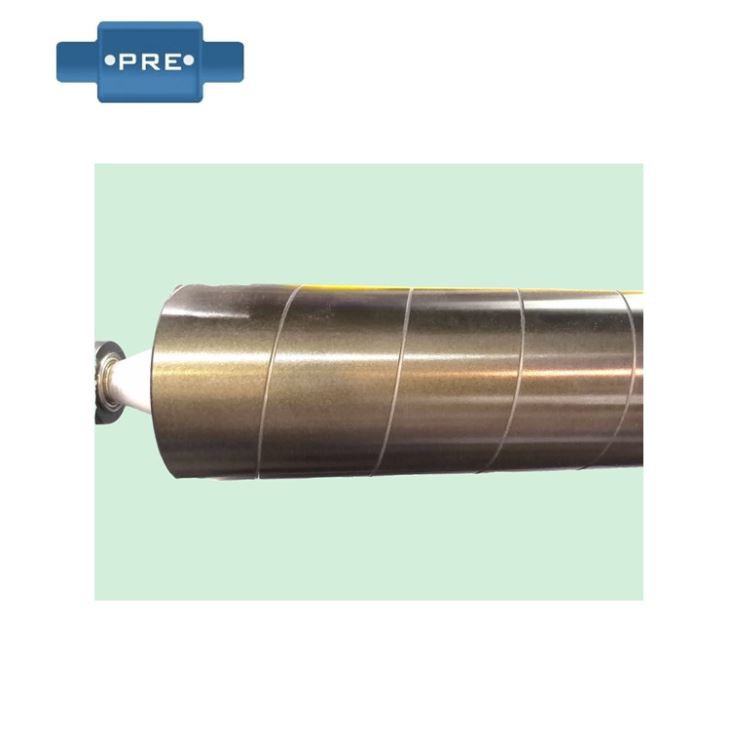

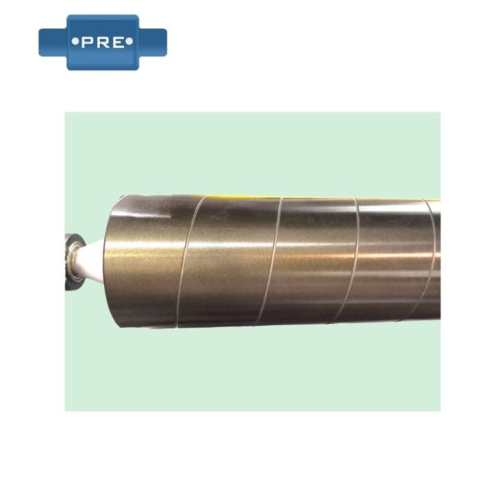

Hard Oxidation Aluminum Idler Roller

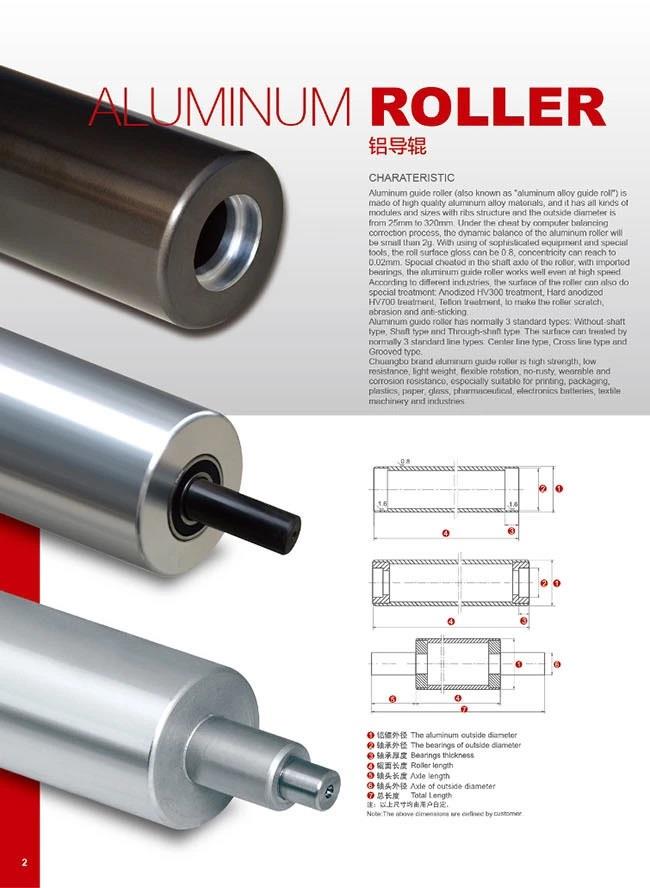

The aluminum guide roller is also called aluminum alloy guide roller. It is made of high-quality aluminum alloy material (6063-T5), and is made into a tube type (from 30mm to 220mm in outer diameter). It has a rib structure and high strength. And using precision equipment and special tools for...

The aluminum guide roller is also called aluminum alloy guide roller. It is made of high-quality aluminum alloy material (6063-T5), and is made into a tube type (from 30mm to 220mm in outer diameter). It has a rib structure and high strength.

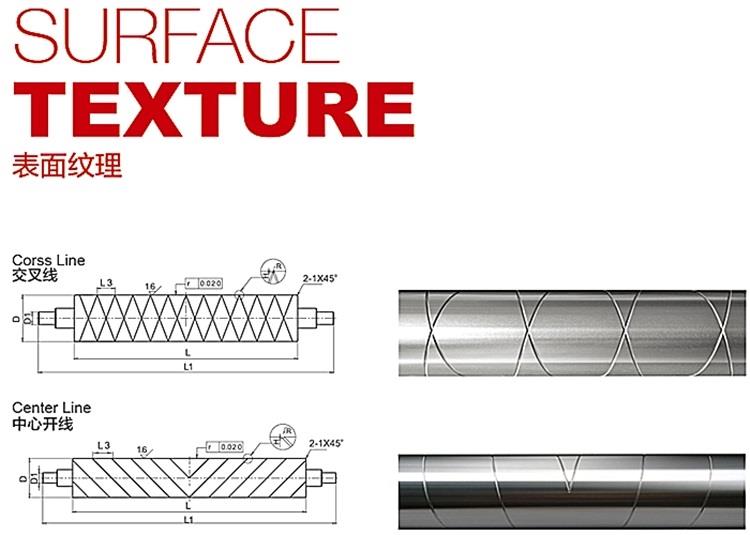

And using precision equipment and special tools for surface finishing, the surface is smooth, the coaxiality reaches 0.02mm, the whole axis is corrected within 2g by computer balance correction, the special technology of the shaft end and the imported bearings can be used under high speed operation. Easy to operate. According to the different needs of the industry, the surface can also be specially treated: sandblasting, reticulated, Teflon and special hardening HV700, which has good scratch and wear resistance.

OD | ID | Wall Thickness | Strong Gluten Mark | Quantity of Strong Gluten |

25 | 18 | 3.50 | A1 | |

28 | 22 | 3.00 | A1 | |

30.1 | 20.1 | 5.00 | A1 | |

33.8 | 25.4 | 4.20 | A1 | |

38.2 | 30.2 | 4.00 | A1 | |

40.1 | 30.1 | 5.00 | A1 | |

45.1 | 32 | 6.50 | A1 | |

50 | 40 | 5.00 | A1 | |

51.4 | 38.8 | 6.30 | A2 | 3 |

52 | 44.6 | 3.70 | A1 | |

55 | 45 | 5.00 | A1 | |

60 | 50 | 5.00 | A1 | |

70 | 61 | 4.50 | A1 | |

71 | 64.6 | 3.20 | A2 | 7 |

75 | 66 | 4.50 | A1 | |

75 | 60 | 7.50 | A1 | |

76.2 | 69.8 | 3.20 | A2 | 7 |

77.4 | 70 | 3.70 | A2 | 9 |

80.7 | 70.3 | 5.10 | A2 | 9 |

81 | 73.2 | 4.00 | A2 | 9 |

90.5 | 82.9 | 3.80 | A2 | 9 |

90.6 | 75.6 | 7.50 | A1 | |

101 | 92.4 | 4.30 | A2 | 9 |

101 | 90.2 | 5.40 | A2 | 9 |

110 | 101 | 4.50 | A2 | 9 |

120.9 | 109.1 | 5.90 | A2 | 9 |

121 | 111.6 | 4.70 | A2 | 9 |

130 | 120 | 5.00 | A2 | 9 |

150.5 | 136.5 | 7.00 | A1 | |

150.9 | 136.9 | 7.00 | A3 | 8 |

151 | 140 | 5.50 | A2 | 10 |

200 | 186 | 7.00 | A1 | |

320 | 296 | 12.00 | A1 |

Understand the different surface treatments or coatings of aluminum guide rolls

Rubber surface: The aluminum guide roller is used as the core shaft, and different rubber layers can provide versatility of different characteristics and different hardnesses. Teflon surface: The special Teflon coating makes the ink easy to clean and provides moderate anti-stick properties.

(1) Universal white oxidized surface: moderate surface hardness HV300, low cost, can also provide different color surface (such as pure black) according to customer requirements, suitable for low tension film industry.

(2) Brown hard oxidized surface: surface hardness of aluminum guide roller HV700 and oxide film thickness of 0.1mm or more. The oxidation technology introduced in Taiwan, high hardness and high abrasion resistance can be applied to various high tension and thick materials. The life of the aluminum guide roller can be greatly improved.

(C) Teflon surface: The special Teflon coating makes the ink easy to clean and provides moderate anti-stick properties.

(4) Rubber surface: The aluminum guide roller is used as the core shaft, and different rubberized layers can provide versatility of different characteristics and different hardnesses.

(5) Industrial hard chrome surface: the highest surface hardness and corrosion resistance, surface roughness can be as low as Ra0.01 (ultra-mirror surface), compared with traditional chrome-plated steel roller, light-weight chrome-plated aluminum roller can be applied to higher speed machine.

Common cleaning method for aluminum rolls

In the usual use process, it needs to be cleaned and there are many cleaning methods. What kind of method does the aluminum roller often take?

1. Manual cleaning method The cleaning agent is applied to the surface of an aluminum roller, and a copper wire brush is used for cleaning the chrome-plated metal aluminum roller; and the ceramic aluminum roller must be cleaned with a wire brush. This type of cleaning method is convenient and does not cause pollution, but if it is not thoroughly cleaned, it will affect the ink transfer effect. Generally suitable for low-wire aluminum rollers or not very dirty aluminum rollers.

2. Chemical cleaning method Apply the corrosive cleaning agent evenly on the surface of the aluminum roller. If necessary, wrap a layer of plastic products on the surface of the aluminum roller to prevent the liquid from volatilizing. The aluminum roller is ablated for 1 to 48 hours. After fully softening, the aluminum roller is washed with water or alcohol ** combined with manual cleaning. Such a cleaning method has a good cleaning effect, but has a certain corrosive effect on the aluminum roller and causes environmental pollution.

3. Ultrasonic cleaning method: The aluminum roller is immersed in an ultrasonic cleaning tank filled with a chemical cleaning solution. When cleaning, the aluminum roller rotates slowly, and the frequency conversion device capable of transmitting high-frequency sound waves in the liquid pool starts to work, causing the solution to vibrate and generate bubbles. Initiating inward, the ink is ejected from the cell, and the cleaning time is generally 15 to 45 minutes.

Application

Packing

Order Details

Item Name | Aluminum roller |

MOQ(Minimum Order Quantity) | 1PC |

Lead time | 10-15 days after receiving the deposit |

Calculated Weight | Need to count |

Package | Wooden Box/Pallet packing/according to clients' demand |

Price Term | EXW,FOB, CIF, etc |

| Payment term | TT,L/C,Western Union |

| Country of Origin | China |

Hot Tags: hard oxidation aluminum idler roller, China, manufacturers, suppliers, factory, quotation, pricelist, buy