Impact Roller

Where should the correct maintenance of the aluminum guide roller start? The correct maintenance of the reticulated aluminum guide rolls should begin with the confirmation of the current use of the reticulated aluminum guide rolls, including the state of the components on the press, such as...

Where should the correct maintenance of the aluminum guide roller start?

The

correct maintenance of the reticulated aluminum guide rolls should

begin with the confirmation of the current use of the reticulated

aluminum guide rolls, including the state of the components on the

press, such as gears, bearings, squeegee systems, etc. This confirmation

process can be combined with the machine. The routine maintenance work

or troubleshooting process is carried out simultaneously.

Carefully

use some magnifiers to carefully observe the surface of the aluminum

guide roller and the condition of the cells, as well as the relevant

machine parts, and record them in words, such as: bearing wear,

looseness of the anilox roll assembly, resulting in the roll direction

is not stamped. Evenly; the teeth are worn or damaged, the overprint is

not accurate, and the horizontal regular stripes are repeated on the

roll;

The surface of the reticulated aluminum guide roller is

damaged, which causes the volume of the cell at the relevant part to

change, which affects the uniformity of the ink color of the printed

sheet; the operation of cleaning the anilox roll is inappropriate,

insufficient or damages the anilox roll, affecting the color of the ink,

and appears Stripes or ink leaks or stains. If such defects are

discovered during the printing preparation time, it will inevitably

delay production and increase losses. Regular inspections and

maintenance should be performed during routine equipment maintenance

work.

O.D(mm) | I.D(mm) | Wall Thickness | Stiffener |

Ф32 Ф33 Ф40 | Ф24 Ф27 Ф34 | 4:00 3:00 3.00 |

8 |

Ф40.5 Ф42.5 serrated roller Ф43.8 | Ф31 Ф30 Ф34.5 | 5.00 4.50 5.00 | |

Ф47 Ф50.5 Ф51 with groove | Ф40.8 Ф40.5 Ф38 | 3.00 5.00 6.50 | 8

6 |

Ф55 Ф58.5 Ф61 | Ф46.5 Ф51.5 Ф51 | 4.50 3.50 4.90 | 6 8 6 |

Ф70 serrated roller Ф71 Ф71 | Ф46 Ф63.2 Ф61 | 7.20 4.50 3.50 |

8 7 |

Ф74.5 Ф75.5 Ф80 | Ф60 Ф66 Ф73 | 7.20 4.50 3.50 |

8 8 |

Ф81 Ф81 Ф80 | Ф72.5 Ф71 Ф69 | 4.30 5.00 5.50 | 8 8 8 |

Ф90 Ф99 Ф101 | Ф81 Ф90.5 Ф92 | 4.50 4.30 4.50 | 8 8 7 |

Ф101.5 Ф101 Ф101 | Ф91.5 Ф89 Ф86.3 | 4.50 11.00 11.00 | 7 8 8 |

Ф111 Ф115 Ф116 | Ф102 Ф93 Ф94 | 4.50 11.00 11.00 |

7 8 |

Ф120.5 Ф121.5 Ф130.5 | Ф105.5 Ф111.5 Ф118 | 7.50 5.00 6.25 |

9 |

Ф140 Ф145 Ф151.5 | Ф120 Ф123 Ф139.5 | 10.00 11.00 6.20 | 8 7 8 |

Ф151.5 Ф153 Ф162 | Ф131.5 Ф121 Ф148 | 10.00 11.00 7.00 |

9 |

Ф184 Ф203 | Ф168 Ф179 | 8.00 12.00 | |

Ф150.5 Ф151 Ф200 Ф320 | Ф136.5 Ф140 Ф186 Ф296 | 7.00 5.50 7.00 12.00 |

10 |

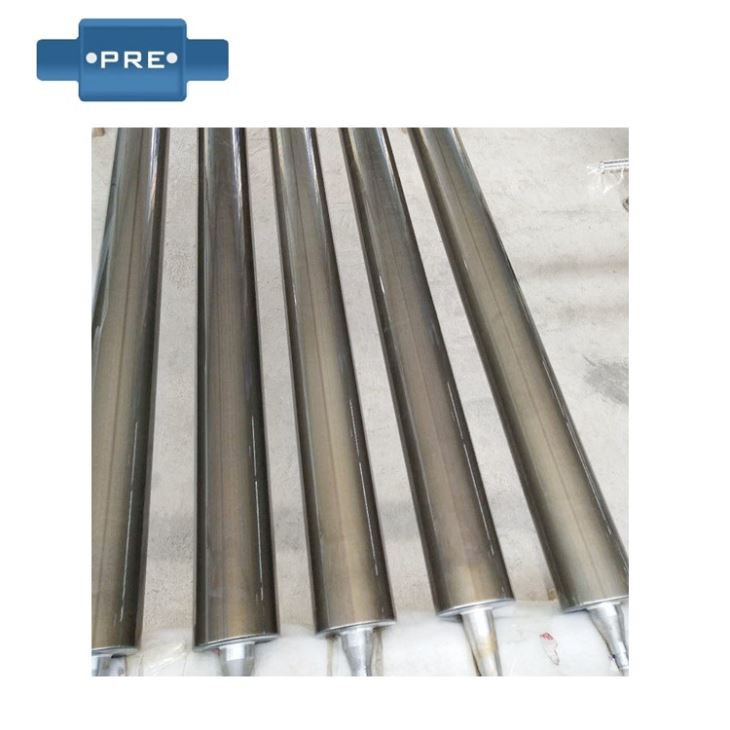

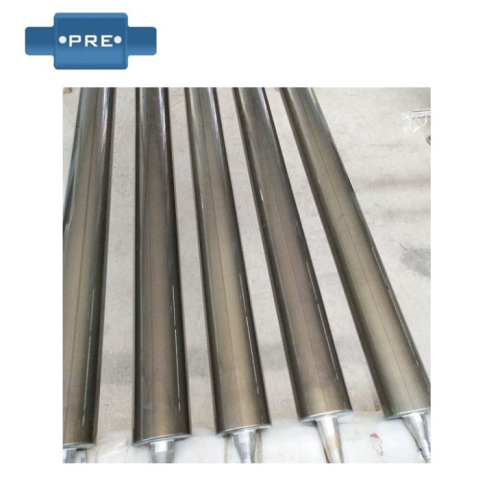

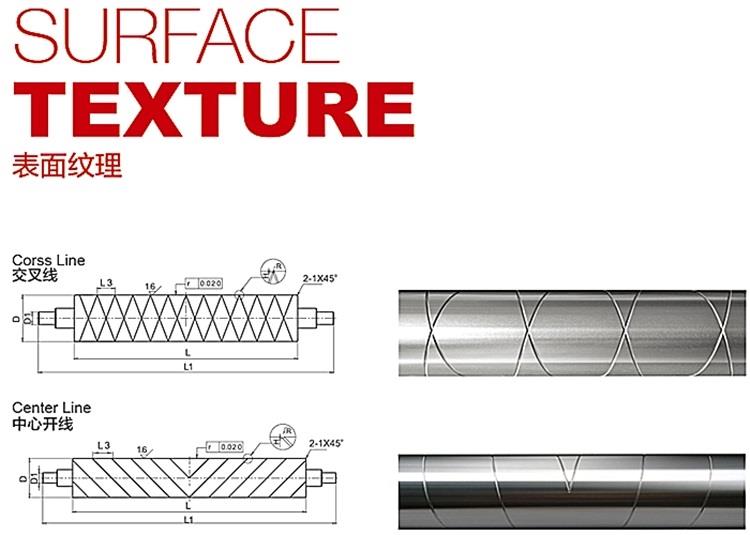

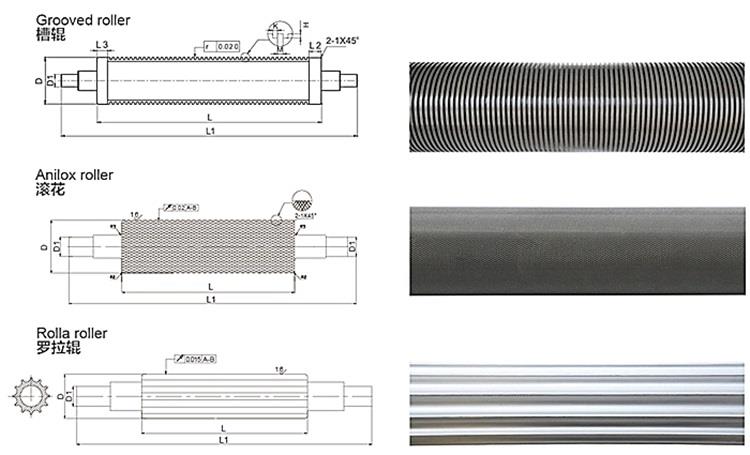

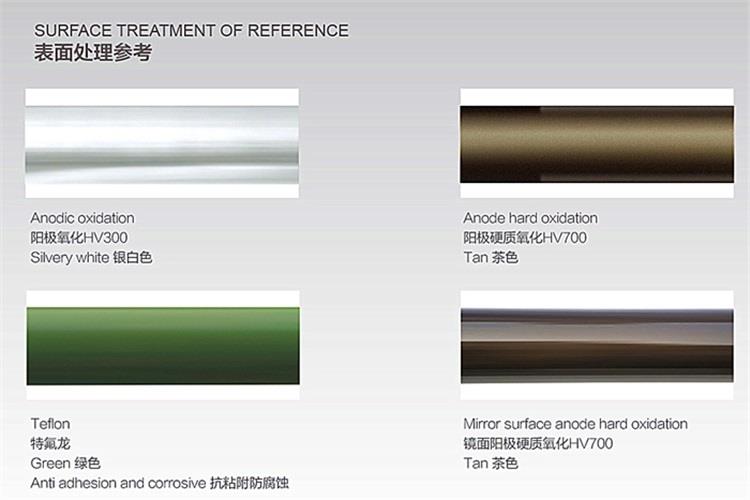

The aluminum guide curler is likewise known as the aluminum alloy guide roller. it's miles manufactured from super aluminum alloy material, and has numerous specifications of the tube via the mold. it has a reinforced rib structure and excessive energy. and using precision device and unique gear for floor completing, the floor is clean, the coaxiality reaches 0.02mm, the entire axis is corrected inside 2g through pc stability correction, the special generation of the shaft end and the imported bearings may be used underneath high pace operation. clean to operate. according to the specific desires of the industry, the floor can also be in particular treated: sand blasting, reticulation, teflon and unique hardening treatment, so that it has top scratch resistance and wear resistance.

The aluminum guide roller has a dynamic rubber-to-bond bond electricity. the aluminum guide rollers are dynamic degreasing for each piercing and the most pre-emptive shaft, non-water, degreasing machine after which ensuring that the tainted steel is pierced. every of the guide roller primers is carefully selected to suit the unique polymer-cured substrate. all aluminum guide rolls are excessive strain injection molded in maximum modern-day machines.

Vulcanization using this manner permits us to supply an limitless variety of thermoset or thermoplastic polymers for any application designed to deliver most performance. aluminum manual rolls are available in a huge variety of floor finishes and diameter beating .001.

Precision grinding device can sharpen the tolerance of the material rolls and our maximum superior profiling era permits us to lessen the style of paperwork required to addiction your precise manual curler.

Application

Order Details

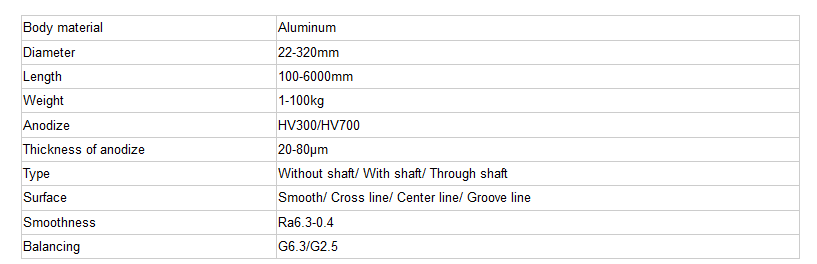

Item Name | Aluminum roller |

MOQ(Minimum Order Quantity) | 1PC |

Lead time | 10-15 days after receiving the deposit |

Calculated Weight | Need to count |

Package | Wooden Box/Pallet packing/according to clients's requirement and demand |

Price Term | EXW,FOB, CIF, etc |

| Payment term | TT,L/C,Western Union |

| Country of Origin | China |

Hot Tags: impact roller, China, manufacturers, suppliers, factory, quotation, pricelist, buy