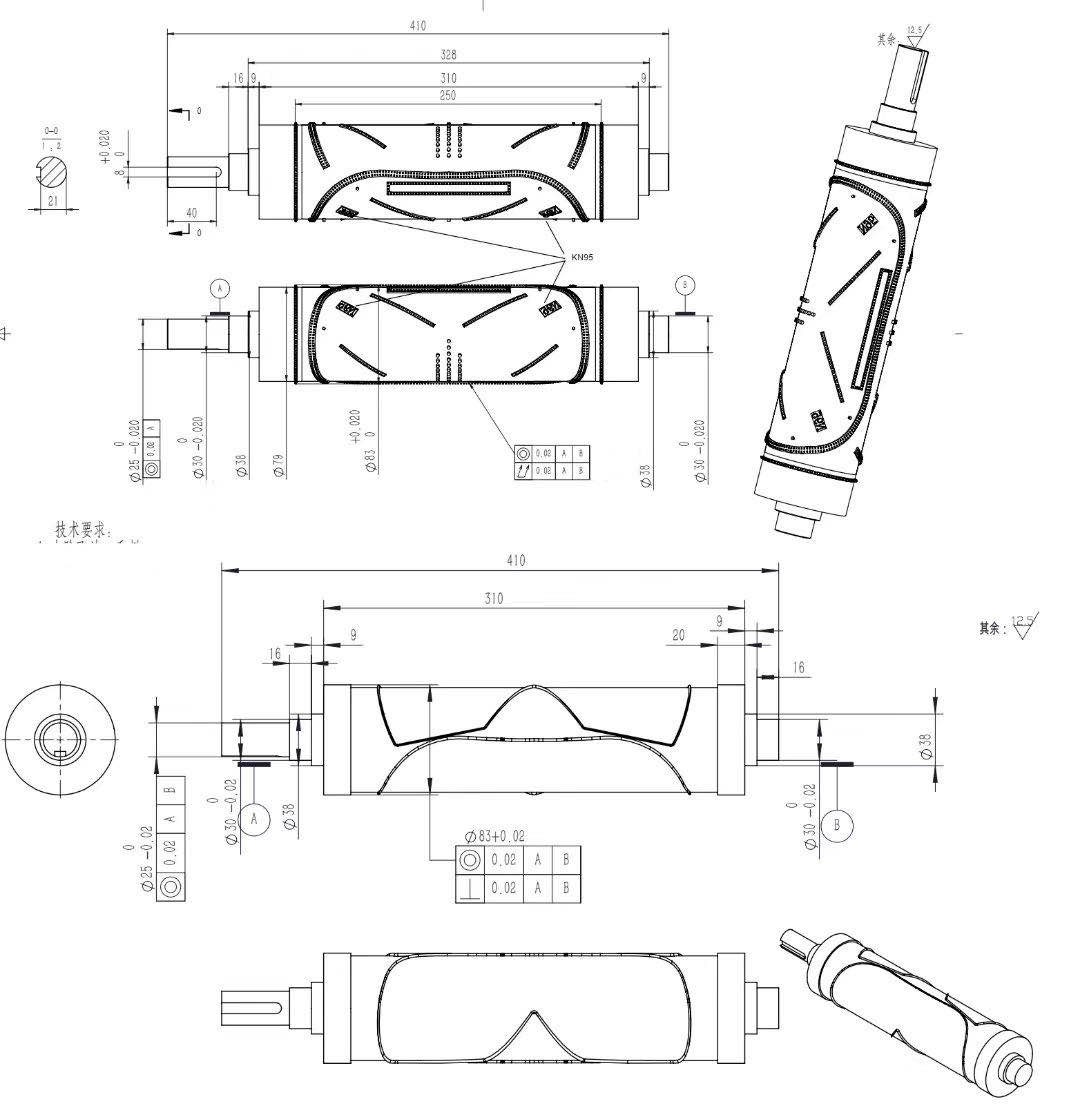

Kn95 N95 Embossing Roller And Cutter Shaft

Introduction Knurling roller and shaft for face mask machine Drawing 1. See clearly customer process requirements and work order requirements. 2. Check which side of the die-cut product (printed bottom side and printed front side) the base plate that has been slit meets the requirements of the...

Introduction

Knurling roller and shaft for face mask machine

Drawing

1. See clearly customer process requirements and work order requirements.

2. Check which side of the die-cut product (printed bottom side and printed front side) the base plate that has been slit meets the requirements of the work order.

3. Whether the cutting edge is smooth and tight, if the cutting edge has high and low positions, the non-closed will cause the product to cut continuously.

4. Whether the blade is scratched and whether there is a gap, the blade scratch will affect the service life of the blade, and the gap will make the product cut continuously.

5. Whether the bridge position is too high or too shallow, the bridge position is too high, the knife and line are easy to bend and deform; the bridge position is too shallow, causing the knife and line to be uneven, the knife line cannot be knocked to the end, it is easy to damage the knife and cause the line to burst. (1) The general bridge position should be 0.5 ~ 1mm higher than the layout, except for special customer requirements. (2) The puzzle bridge position cannot be higher than the layout, otherwise it is easy to deform.

6. When the wire hits the bridge position, the direction should be unified. If it is not unified, it will affect the product size and cause poor molding. Because the wire will deform when it hits the bridge position, if the direction is not uniform, the deformation direction of the wire will be the opposite, which will affect the size.

Packaging

Order details

Hot Tags: kn95 n95 embossing roller and cutter shaft, China, manufacturers, suppliers, factory, quotation, pricelist, buy