Tension Controller

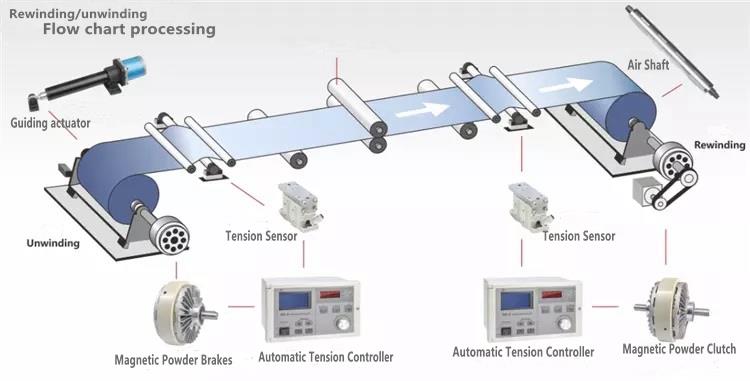

The tension control system is an automatic control system that realizes constant tension or taper tension control. Its function is mainly to achieve synchronization between rolls, uniform control of winding and unwinding. The working principle can be divided into open-loop, closed-loop or...

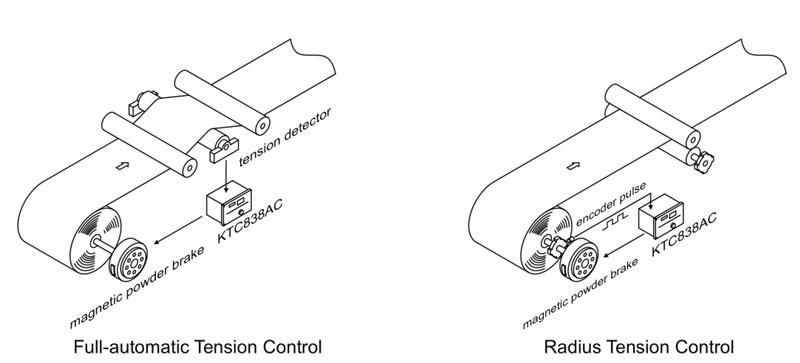

The tension control system is an automatic control system that realizes constant tension or taper tension control. Its function is mainly to achieve synchronization between rolls, uniform control of winding and unwinding. The working principle can be divided into open-loop, closed-loop or free-loop tension control systems according to the loop; according to the monitoring methods of different coils, it can be divided into ultrasonic, floating roller, tracking arm and other control systems. The entire system consists primarily of tension controllers, tension detectors, brakes and clutches. The system is divided into direct tension control and indirect tension control. Control methods include manual control, semi-automatic mode, and fully automatic mode.

Applicable industries: printing, packaging, paper, non-woven, lithium batteries, solar energy, rubber tires, textiles, metallurgy, etc.

Applicable coil: Winding materials such as web, film, metal foil, film, leather, non-woven fabric, woven fabric, etc.

Automatic Tension Controller with Taper and Communication Function

The automatic tension controller is mainly composed of a tension detector, a high-precision A/D, a D/A converter, and a high-performance single-chip microcomputer. The automatic tension controller compares the tension of the coil material with the set target tension according to the tension detector, and automatically adjusts the D/A output by the PID calculation of the single-chip microcomputer to change the magnetic powder clutch, the excitation current of the brake or the torque of the servo motor. To achieve constant tension of the coil material, it can be widely used in various occasions where precision measurement and control is required, and it has flexible use and wide applicability.

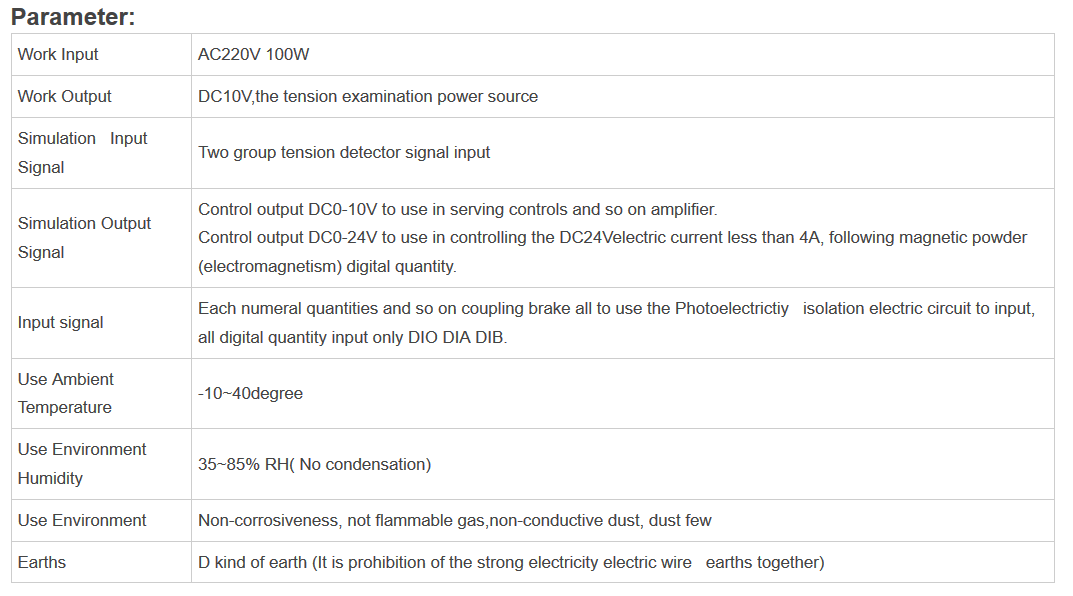

Operating Panel:

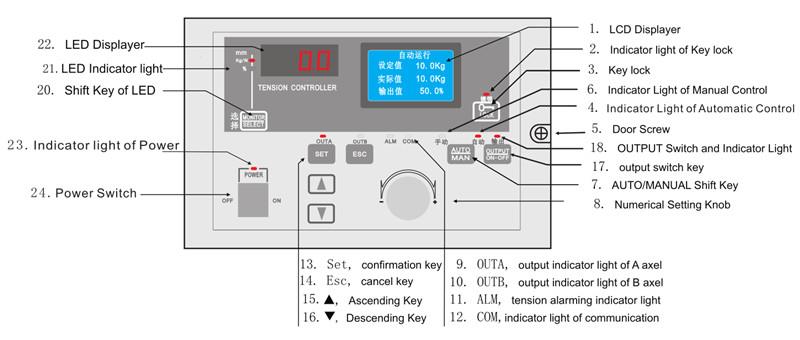

Wiring Diagram:

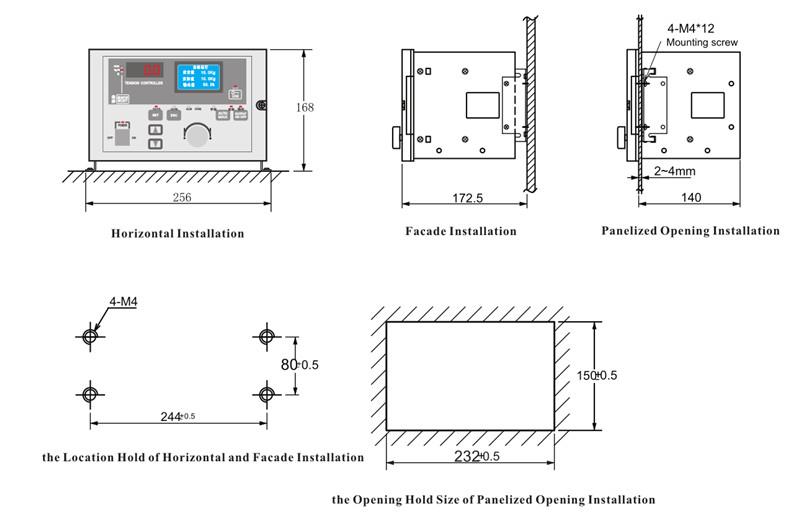

Installation:

Application

Tension controller for gravure press

The producing precision and meeting precision of the main additives of the gravure printing device which include the bottom, the wall panel, the guide curler, and many others. are deviated, and the transmission synchronization mistakes is caused in the course of the printing manner, which is bound to change the anxiety of every printing unit, and the gravure printing system is wound up. all through the unwinding manner, the winding and unwinding diameters are continuously changing. the exchange in diameter need to purpose the tension of the belt to exchange. whilst the braking torque is steady, the diameter is reduced and the tension will growth.

Tension controller have to be effective for any speed of the gadget, such as acceleration, deceleration and uniform speed of the gadget. it also has the capacity to make sure that the belt does not break. the manual gravure manipulate device of the present day gravure press has been essentially eliminated.

Closed-loop automated anxiety control is to at once measure the real anxiety cost of the material belt through the anxiety sensor. by means of evaluating this sign with the preset tension value of the controller, the manipulate sign is calculated. due to the better printing velocity and production process, higher requirements are placed on the tension manage, making the magnetic powder seize incapable of being the govt unit of this kind of gadget.

The Tension controller is strong, the tension exchange is small, and the color registration accuracy and reject charge of the gravure printing device are without problems controlled. the tension control system of the gravure printing gadget is largely a special type of input amount that modifications in keeping with an adjustable attenuation law. dynamic gadget, fluctuation of fabric elastic modulus, cloth thickness variation along the width and length, and so forth., the nice of the coil is eccentric, and the temperature and humidity of the production environment alternate, so that it will have a subtle effect at the tension fluctuation of the entire device. inside the method of automatic refueling without stopping the machine, the cloth receiving and breaking will reason the unexpected tension of the authentic machine to abruptly trade.

Magnetic powder brakes and magnetic powder clutches are extensively utilized in papermaking, printing, plastics, rubber, textile, printing and dyeing, wire and cable, metallurgy, tablet presses and different associated winding and winding anxiety control, tension manipulate way the ability to completely manipulate the anxiety of the tape as it's miles transported on the device.

Order Details

Item Name | KTC-838A Automatic Tension Controller with Taper and Communication |

MOQ(Minimum Order Quantity) | 1pc |

Lead time | 2 days after receiving the deposit |

Calculated Packing Size | 20cm*15cm*15cm,2kg/pc |

Package | Carton |

Price Term | EXW,FOB, CIF, etc |

Payment term | TT,L/C,Western Union |

Country of Origin | China |

Hot Tags: tension controller, China, manufacturers, suppliers, factory, quotation, pricelist, buy