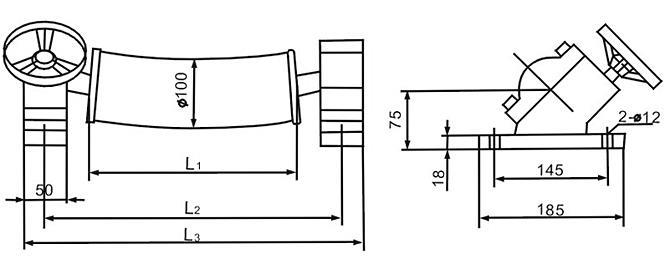

Curved Roller

It is suitable for processing machinery for film, paper, textile, metal foil and other products to prevent wrinkles and stretch and stretch during the operation of the substrate. Technical Parameters 2, characteristics ●High line speed, low jitter, no noise ● Small rotating torque and can...

It is suitable for processing machinery for film, paper, textile, metal foil and other products to prevent wrinkles and stretch and stretch during the operation of the substrate.

Technical Parameters

| Roll surface diameter | Ø80, Ø100, Ø125, Ø150 |

| Roll length | 200-3600mm |

| Substrate roll angle | 15°-30° |

| Roll line speed | <300m/min |

| Rubber variety | Butadiene rubber, EPDM rubber, silicone |

2, characteristics

●High line speed, low jitter, no noise

● Small rotating torque and can withstand large pulling force

● Good sealing performance, waterproof, acid and alkali resistance

● Safe and durable, easy to install and debug

● There is a unique flattening function for the substrate to appear in the middle of the tight side of the two sides or the loose side of the middle.

The flattening ability is relatively small, the angle of the substrate wrapping roller should not be too large or the tension is too large, otherwise the film-based substrate may be permanently deformed, the paper substrate may be broken, and the cloth substrate may be bent in the weft direction. It is sometimes necessary to adjust the direction of the curvature in time depending on the condition of the substrate.

The curved flattening roller is widely used in textile, printing and dyeing, printing, papermaking, film, packaging and other industries. It is a variety of products with wide application range and large dosage.

Curved roller mounting arrangement

In order to achieve the best stretching effect, the arc roller should be kept at a certain length between the introduction roller and the arc roller. The lead roller and the curved roller should be as short as possible.

1. The distance between the introduction roll and the curved roll is at least twice the distance between the take-up roll and the curved roll.

2. The distance between the take-up roll and the curved roll is twice the roll diameter.

Packing

Order Details

Item Name | Curved roller |

MOQ(Minimum Order Quantity) | 1PC |

Lead time | 10-15 days after receiving the deposit |

Calculated Weight | Need to count |

Package | Wooden Box/Pallet packing/according to clients's requirement and demand |

Price Term | EXW,FOB, CIF, etc |

| Payment term | TT,L/C,Western Union |

| Country of Origin | China |

Hot Tags: curved roller, China, manufacturers, suppliers, factory, quotation, pricelist, buy