Friction Ring

A main shaft structure of a slip shaft and a slip ring thereof, the slip shaft comprises a main shaft body, a plurality of roller units and a plurality of air rising units, and the roller unit is arranged at the outer circumference of the main shaft, and can provide various slips The ring is...

A main shaft structure of a slip shaft and a slip ring thereof, the slip shaft comprises a main shaft body, a plurality of roller units and a plurality of air rising units, and the roller unit is arranged at the outer circumference of the main shaft, and can provide various slips The ring is sleeved and rolled. The slip ring has two ring bodies and one cam element. The two ring bodies can be combined in a combined or overlapping manner to accommodate different sizes of reels. The utility model is provided with a plurality of friction wheels, and the rotating cam element can push the friction wheel to protrude and clamp the reel, and the magnetic component is embedded in the cam element, and the friction wheel can be hidden, thereby achieving the convenience of operation and cost saving.

The slip ring is a unit on the slip axis, mainly in the winding process, because the material's winding tension is too large, and the material winding is easy to occur, and the slip ring plays a big role. It can eliminate the tension of the material to achieve the desired winding state.

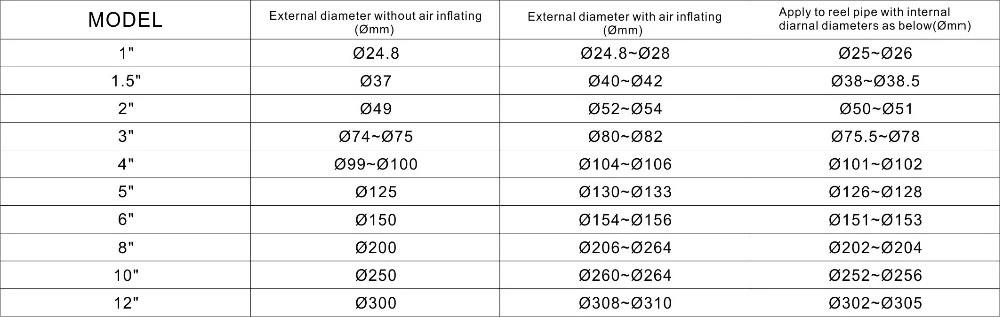

The types of slip shafts are different, the slip rings are different, and the width of each slip ring is also different.

Key friction ring: The commonly used width of the key slip ring is 10mm, 15mm, 20mm, 37mm, 50mm;

Ball slip ring: the standard width of the ball slip ring is 25mm;

East extension slip ring: the width of the east extension slip ring is 50mm;

West Village slip ring: West Village slip axis has 30mm, 40mm, 45mm, double gas road West Village slip ring has 22mm, 40mm, 45mm.

Each type of slip axis has its own advantages and disadvantages. Or, each type of slip axis is based on the width of the customer's needs, and the material to be cut to select which kind of slip axis. For example, the ball roller slip shaft is mostly used in our adhesive industry. PET, PE and other membranes use key-type slip shafts. Sheets and the like use the east extension slip shaft. The diaphragm of the lithium battery industry uses the double-gas road. In the lithium battery industry, most of the ear and pole pieces use the West Village slip axis.

Application

Technique parameter

Order Details

Item Name | Friction Rings |

MOQ(Minimum Order Quantity) | 20Pcs |

Lead time | 15-18 days after receiving the deposit |

Calculated Weight | Need to count |

Package | Wooden Box |

Price Term | EXW,FOB, CIF, etc |

Payment term | TT,L/C,Western Union |

Country of Origin | China |

Hot Tags: friction ring, China, manufacturers, suppliers, factory, quotation, pricelist, buy