Linear Actuator

The high-precision, high-velocity, high-efficiency coil cloth automated processing method of the manual device has higher and better necessities for the manage of the lateral position of the coil. geared up with a high-performance automated guide gadget is the key to improving the manufacturing...

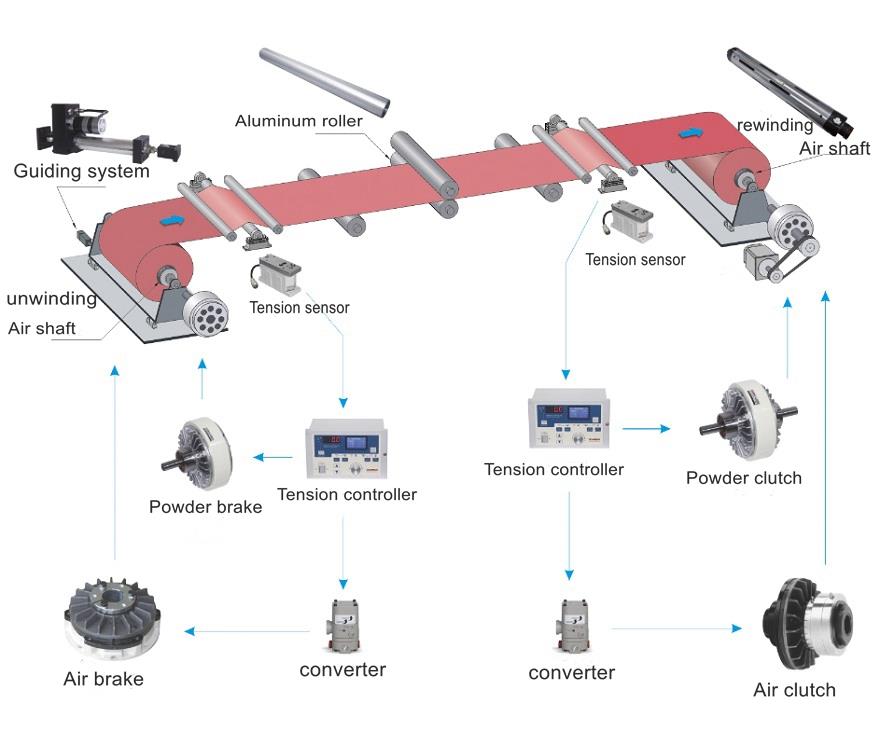

The high-precision, high-velocity, high-efficiency coil cloth automated processing method of the manual device has higher and better necessities for the manage of the lateral position of the coil. geared up with a high-performance automated guide gadget is the key to improving the manufacturing capacity and yield of coils. the coil will produce lateral displacement (running deviation) at some point of travel, unwinding and winding, so the guide system can be mounted within the above 3 positions to manipulate the proper passing of the coil.

The system makes use of excessive-velocity microprocessor, digital, modular, intelligent circuit design; superior programming, user-friendly interface, lcd display show; excessive-performance additives and perfect circuit protection design to make the system run continuously and stably; manipulate gadget response the time is less than 0.01 seconds; the accuracy of the system itself is as much as 0.01mm. all through the cloth winding manner, the placement of the brink or line is detected by way of the photoelectric sensor to pick out up the edge manual body or line position deviation sign. then, the placement deviation signal is transmitted to the photoelectric manual controller for common sense operation, and a control sign is sent to the mechanical actuator to pressure the mechanical actuator to accurate the serpentine deviation of the material throughout operation to make certain linear motion of the fabric. optionally available left and right restriction switches save you the gadget from going for walks out of manage.

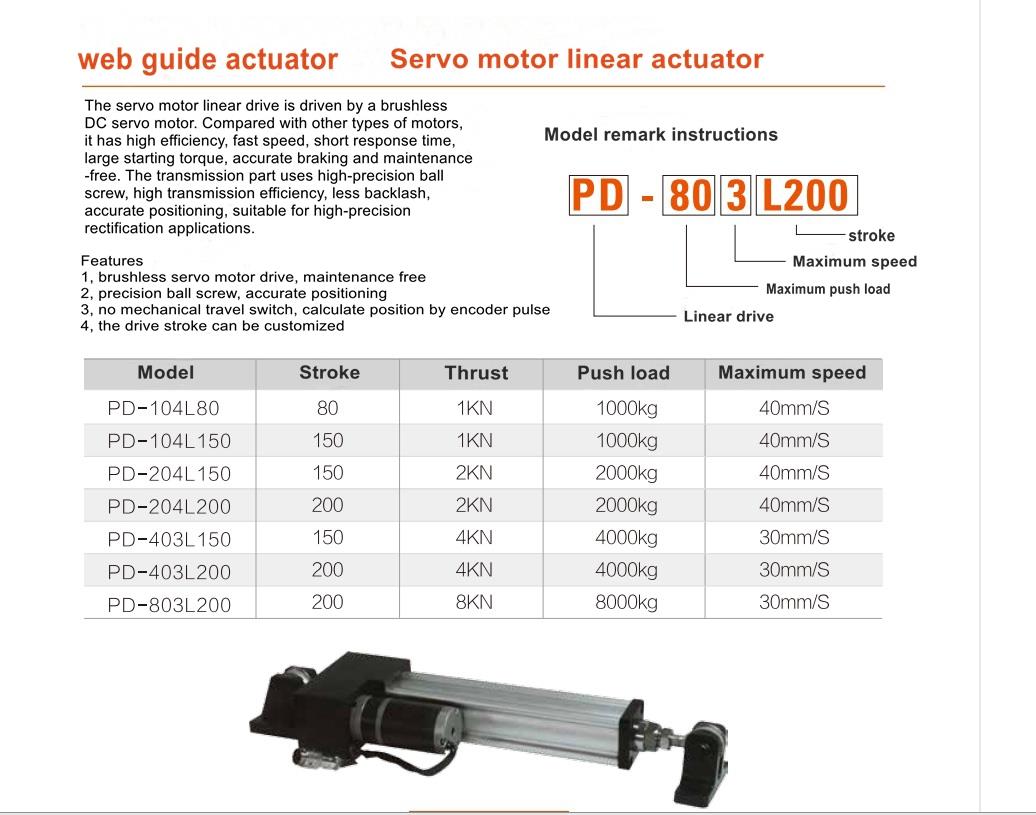

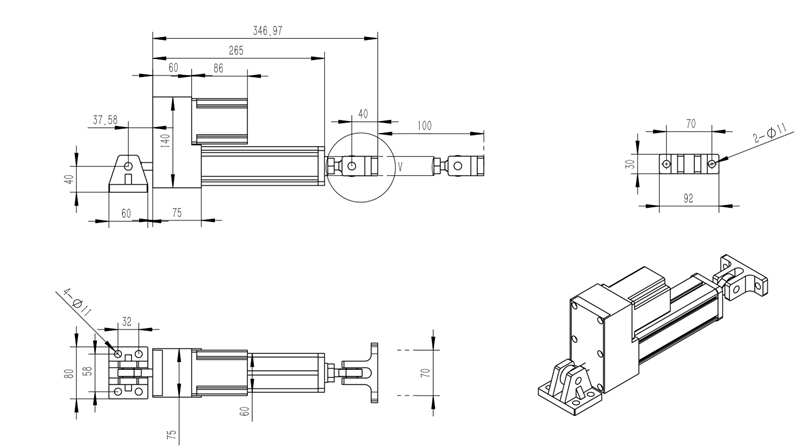

The servo motor linear drive is driven by a brushless DC servo motor. Compared with other types of motors, it has the characteristics of high efficiency, fast speed, short response time, large starting torque, accurate braking and maintenance-free. The transmission part uses high-precision ball screw, which has high transmission efficiency, less backlash and accurate positioning, and is suitable for high-speed and high-precision correcting applications.

Servo pusher features:

1,Precision ball screw

2,Brushless servo motor

3,Silent timing pulley

4,Built-in encoder and limit

5,Maintenance free long life

Actuator

The rectifying device is mainly used for the lateral

deviation control of the reel material, and can be used for various coil

materials such as web film, metal foil, non-woven fabric, woven fabric,

etc. on a long and fast production line, because of speed, Pulling

force or uneven thickness of materials and various types of mechanical

damage, causing the material to move left and right on the production

line and unidirectional deviation, so that the processing action in the

middle section is not easy to match, or the movement of the front and

rear sections is not smooth, resulting in many materials. Loss and

subsequent processing difficulties. The photoelectric-to-edge

line-to-line device can solve this problem. The corrector is used for:

coating machine, self-adhesive machine, laminating machine, slitting

machine, rewinding machine, packaging and printing machinery, etc.

Packing:

Order Details

Item Name | Web Guide Actuator |

MOQ(Minimum Order Quantity) | 1Set |

Lead time | 2-3 days after receiving the deposit |

Calculated Packing Size | According to model |

Package | Carton/Wooden Box |

Price Term | EXW,FOB, CIF, etc |

Payment term | TT, L/C,Western Union |

Country of Origin | China |

Hot Tags: linear actuator, China, manufacturers, suppliers, factory, quotation, pricelist, buy